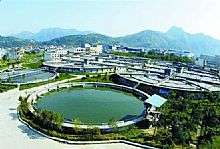

Steel degassing mechanical vacuum pump system

Steelmaking under vacuum

Steel is defined as iron-carbon alloys containing less than 2 % of carbon, which may additionally contain other alloying elements. The result is a wide range of different steel variants: construction steels, tempering steels, stainless, heat-resistant and cold-resistant steels are just a few examples.

Although they differ in application and properties, all steels contain iron and varying amounts of other elements. The proportions of these elements generally determine the steel’s physical properties, particularly those elements that are not desirable:

■ Sulfur

■ Nitrogen

■ Hydrogen

The basic requirement for any highquality steel is the removal of these elements from the steel in order to improve the material properties such as:

■ Impact resistance

■ Aging resistance

■ Impact strength

■ Elongation

■ Weldability and malleability

The processes used to refine liquid steel are referred to by the term “secondary metallurgy”. A removal of these elements from steel can be achievedby various vacuum processes. EVP Vacuum focuses on the Vacuum Degassing (VD) and the Vacuum Oxygen Decarburisation (VOD) processes.

In both processes, a ladle of liquid steel is placed inside a vacuum chamber, which is evacuated by a corresponding vacuum system. By the aid of appropriate feeding systems, other alloying elements can be added to obtain the desired steel composition.

In vacuum processes, substances will outgas or evaporate from the liquid steel (depending on their vapour pressure). This leads to additional gas loads for the vacuum system. During the evacuation process, the following substances/fumes, which place high demands on the robustness of the pumps in use, may be present:

■ Metallic and metallic oxide dust/fume

■ CO, CO2 (VOD process)

■ Hydrogen (H2), Nitrogen (N2)

The VD process uses pressures below 1 hPa (0.75 Torr) and stirring with Argon to remove these non desired elements.

The VOD process applies a lance to blow oxygen onto the melt and starts at a pressure of 100 to 200 hPa.In the production of high alloyed stainless steel, raw material costs represent roughly 80 % of the manufacturing costs.

To control the raw material cost, high carbon ferroalloys and stainless scrap have to be used, yet stainless steel must also have a very low carbon content to inhibit corrosion. The VOD process can be employed to remove carbon from the liquid steel.

In the VOD process, there are two competing reactions; carbon oxidation and chrome oxidation. The second reaction is not desirable. Fortunately, the products of these two reactions differ significantly: Carbon monoxide (CO) is a gas and chrome oxide (Cr2O3) is a solid chemical compound. This difference makes it possible to favor carbon oxidation by lowering the partial pressure of CO. In a VOD, this is achieved by vacuum. Consequently, the carbon content in the liquid steel can be reduced to the desired low level.

Energy-efficient alternative to steam ejector pump systems

In recent years, low energy consumption and environmentally friendly products have become increasingly important. This trend can also be observed where vacuum systems are concerned. Previously, mainly EVP steam ejector pumps were used for steel degassing. While purchasing costs for the ejector pumps are low, operating costs for steam production and cooling water are very high, as the created dust contaminates the cooling water. For this reason, EVP mechanical vacuum pumps are increasingly used today. They are cost effective and have a high pumping capacity at low pressures. Equipped with a dust filter, they offer reliable and stable performance under various conditions. Steel degassing mechanical vacuum systems compared to steam ejector pump systems can achieve substancial operating and maintenance cost savings. These pump system stages consist of gas-circulation-cooled Roots pumps, Roots pumps and screw pumps.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)