Roots blower on melt blown cloth production line

Since the sudden outbreak of COVID-19 at the end of 2019, masks in many countries are in short supply! Let the raw material of meltblown cloth enter everyone’s sight. Melt blown cloth is the core material of the mask. The melt blown cloth is mainly made of polypropylene, and the fiber diameter can reach 1 to 5 microns. There are many voids, the structure is fluffy, and the ability to resist wrinkles is good. The ultrafine fibers with unique capillary structure increase the number and surface area of fibers per unit area, so that the melt blown cloth has good filter ability, shielding, heat insulation and oil absorption. It can be used in air&liquid filter materials, isolation materials, absorbing materials, mask materials, thermal insulation materials, oil absorbing materials and wiping cloths.

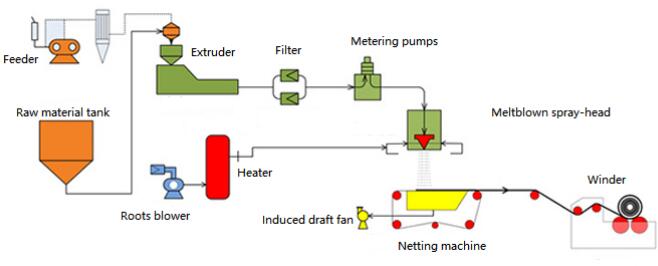

With the outbreak of the epidemic, how to ensure the timely supply of masks has become a top priority. On the one hand, we need to increase the production capacity of masks, and on the other hand, we need to ensure the supply of mask raw materials, especially melt blown cloth. So how to produce the melt blown cloth? The automatic feeder automatically sucks in 100% drawing-grade polypropylene and sends it to the extruder. The extruder heats and melts the PP particles to a liquid state. Roots blower compress air into the oven for heating. The hot air uses pressure to spray the molten polypropylene material from the nozzle to form filaments (the nozzle contains hundreds of small holes), and then spray the outgoing filaments reach the receiving equipment horizontally, and then roll the non-woven fabric with a rolling machine. Please see the P&ID below.

Roots blower is a very important equipment in the melt blown cloth production line. EVP developed automatically new model based on the technical characteristics of various types of roots blowers at oversea and domestic. The research and development of the product used advanced CAD paving design and advanced processing technology to ensure the performance of the fan, and has been widely used in the fields of national economy: sewage treatment, flour, aquaculture, pneumatic transportation, electric power, cement and other industries . The product has a wide range of capacity, densely divided files, and high boost pressure. There are nearly 20 models and more than 100 specifications.

Roots blowers produced by EVP have the following advantages:

(1) Constant-volume fan, without internal compression, is mandatory for conveying gas. With pressure changes, the flow rate changes very little.

(2) The product adopts a three-blade linear impeller, with smooth air intake and exhaust pulsation and low noise.

(3) The impeller adopts a special curve to make the meshing more reasonable, high efficiency, and low energy consumption. It is a new energy-saving product.

(4) The product adopts a variety of new structural designs to make the whole machine compact, small in size, light in weight, and beautiful in appearance.

(5) The product adopts high-precision hard-tooth synchronous gears with long life and low noise.

(6) The conveying air is clean and does not contain any oily dust

Edited by: Lany SHEN; Copyright: EVP Vacuum Pump

Related products: Roots blower

Application: Melt blown cloth production line.