rotary vacuum pump in vacuum filter

To understand why the vacuum filter chooses the rotary vane vacuum pump. The vacuum filter (before start-up) of the concentrator and large water pump requires the vacuum pump to extract air from it. Because vacuum pump is a kind of compressor, it draws gas from thin air space and discharges it into the atmosphere. In general, the pressure of the gas it inhales is lower than atmospheric pressure (the recently manufactured vacuum pump can make the residual pressure in the container 1 × 10-15mm silver column larger), and the pressure of the gas discharged is slightly higher than atmospheric pressure.

The vacuum pump also has reciprocating vacuum pump, rotary vane vacuum pump and so on. Its working principle will be described later.

At present, the vacuum pump used in the concentrator has a rotary vane vacuum pump. The rotary vane vacuum pump only draws air from a certain space (such as the air in the filter), and it can extract 98% of the air. The wet air pump sucks out the liquid and air together and can only empty 85%. In order to maintain a certain volume of vacuum pump and heat dissipation, water must be continuously circulated. In order to supply water to the vacuum pump, a special water tank connected to the discharge pipe is arranged, and a gate valve is arranged on the water tank to regulate the circulating water volume. The used water is put into the box with air. In order to avoid blade end wear, there should be no inclusions in the circulating water, otherwise the blade will wear, the pumping capacity will decrease with the increase of wear, and the general wear should not exceed 0.1mm.

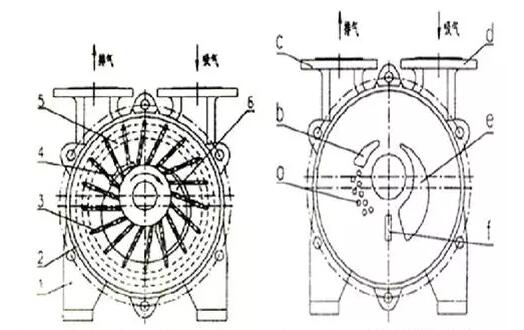

Working principle of vane vacuum pump: vane pump is mainly composed of stator, rotor, vane, fixed cover and spring. The structure is a rotor installed eccentrically in the stator cavity (the gap between the outer circumference of the rotor and the inner surface of the stator is very small) and the sliding in the rotor groove is closely attached to the inner wall. The stator is affected by spring tension and centrifugal force. When the rotor rotates, the two rotating parts always slide along the inner wall of the stator.

The crescent space surrounded by the rotor, stator cavity and fixed cover is divided into three parts a, B and C. when the rotor rotates in the direction shown, the volume and suction port of space a increase continuously, and the pressure in space a decreases continuously. When the pressure in space a is lower than the pressure in the pumping vessel, according to the principle of air pressure balance, the pumped gas is continuously sucked into suction chamber A. during suction. The space volume of cavity B decreases gradually and the pressure increases continuously. Now it is in the process of compression. The volume of space C connected with the exhaust port is further reduced, and the pressure of space C is further increased. When the pressure of the gas is greater than the exhaust pressure, the compressed gas pushes the exhaust valve to continuously exhaust the gas. The ground passes through the reservoir in the tank and is vented to the atmosphere. During the continuous operation of the pump, the suction, compression and exhaust processes are carried out continuously to achieve the purpose of continuous pumping.

The exhaust valve is immersed in oil to prevent air from entering the pump. The oil enters the pump chamber through the clearance, oil hole and exhaust valve on the pump body, so that all the movable surfaces in the pump chamber are covered by oil, forming an air intake chamber, and the exhaust chamber is sealed. At the same time, the oil fills all the harmful spaces to eliminate its impact on the extreme vacuum.

Why choose the main pump of rotary vane vacuum pump in vacuum filter?

1. The limiting pressure determines the type of main pump

2. Select the working pressure required in the production process as the main pump.

3. Select the main pump for the volume of the vacuum chamber and the required pumping time

4. Correct combination of vacuum pump

5. Judge whether there is oil type or no oil type according to the requirements of cleaning vacuum

6. Select vacuum pump according to the characteristics of gas composition

7. Select the main pump according to the economic indicators, such as the initial investment and the daily maintenance cost of the whole vacuum system.

rotary vacuum pump in vacuum filter

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)