Rotary vane vacuum pump for freeze drying

Freeze drying

Freeze drying, also known as freeze drying, is a particularly mild drying process and is therefore suitable for sensitive products. In pharmaceuticals and biotechnology, lyophilized substances include temperature-sensitive vaccines, antibiotics and bacteria. Dry them directly in a glass bottle or syringe and store them in a few seconds if needed. The purity and sterility of the system are particularly required when drying injectable products. For this purpose, vacuum provides support not only for the cleaning of vacuum products, but also for the monitoring of drying chamber.

Vacuum requirement

For freeze-drying, the pressure must be below the triple point of the solvent (e.g. water) used. In addition, unwanted substances such as oxygen are removed from the drying chamber during the vacuum. Although the working pressure during primary drying is usually between 0.5 hPa and 1*10-2 hPa, it can be as high as 1*10-3 hPa during secondary drying or during regulation in the drying chamber.

Product portfolio

Vacuum offers a comprehensive portfolio of freeze-drying products, including vacuum pumps for vacuum pumping, pressure gauges and calibration pump stations, gas analysis mass spectrometers for process monitoring, and leak detectors for leak location.

The products processed by rotary vane vacuum pump have the following outstanding features: keeping the original color, aroma and taste of the products to the maximum extent; For example, the natural pigment of vegetables can remain unchanged, and the loss of various aromatic substances can be reduced to a minimum; It is especially suitable for drying and processing.

Rotary vane vacuum pump technical parameter,freeze dryer with vacuum pump.

| Models | 2XZ -2C | 2XZ-4C | 2XZ-6C | 2XZ-8C | 2XZ-15C | 2XZ-25C | ||

| Pump speed | 50HZ (L/s) | 2 | 4 | 6 | 8 | 15 | 25 | |

| 60HZ (L/s) | 2.4 | 4.8 | 7.2 | 9.6 | 18 | 30 | ||

| 50HZ (m3/h) | 7.2 | 14 | 22 | 29 | 54 | 90 | ||

| 60HZ (m3/h) | 8.6 | 17 | 25 | 35 | 65 | 108 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ² | 6×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | 5×10ˉ² | |

| Total pressure | 1 | 1 | 1 | 1 | 1 | 1 | ||

| Rotary speed(r/min) | 50HZ | 1400 | 1400 | 1400 | 1400 | 1400 | 1400 | |

| 60HZ | 1720 | 1720 | 1720 | 1720 | 1720 | 1720 | ||

| Motor power(Kw) | 0.37 | 0.55 | 0.75 | 1.1 | 1.5 | 3.0 | ||

| Working voltage(v) | 220/380 | 220/380 | 380 | 380 | 380 | 380 | ||

| InletDiam(mm) | I.D. | KF-25 | KF-25 | KF-25 | KF-40 | KF-40 | KF-40 | |

| O.D. | ||||||||

| Dimensions(mm) | Length | 480 | 520 | 545 | 616 | 705 | 830 | |

| Width | 150 | 150 | 172 | 255 | 255 | 275 | ||

| Height | 200 | 200 | 285 | 360 | 360 | 440 | ||

| Noise(dBA) | 65 | 65 | 68 | 70 | 70 | 72 | ||

| Oil capacity (L) | 0.8 | 1 | 1.5 | 3 | 3.5 | 4 | ||

| G.W./N.W. (kg) | 22/20 | 26/22 | 55/46 | 70/60 | 86/75 | 105/85 | ||

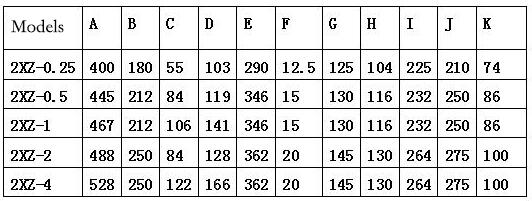

Extraction rate curve

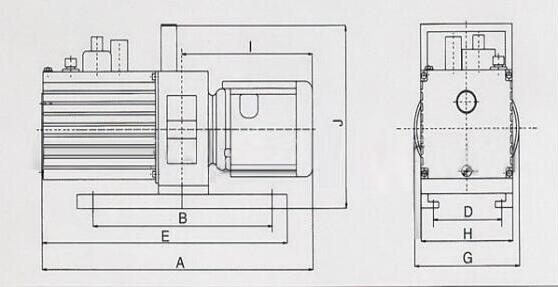

Installation dimension