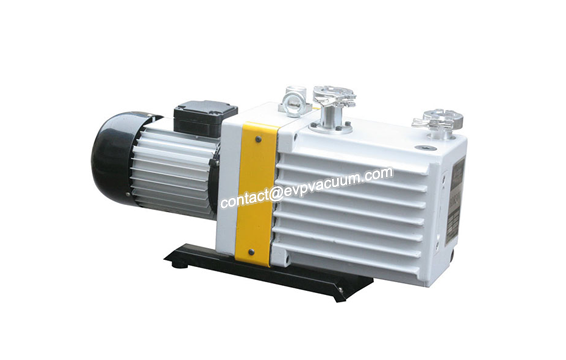

Rotary vane vacuum pump for oil depot

Rotary vane vacuum pump in oil depot of application

The so-called process flow design of oil depot is to reasonably arrange and plan the flow direction of oil products and the operations that can be completed, including loading and unloading, filling and backflow of oil products. The basic principle of process design of oil depot is to meet the production requirements, easy operation, flexible scheduling, saving investment and so on. The vane vacuum pump is applied in the oil depot to meet these conditions. Various types of pumps, classification, different USES. For the oil depot, the commonly used pump can be different according to the number of impeller and structure.

What parameters should be considered when selecting pump in oil depot?

The parameters to be considered when selecting pump in oil depot are as follows:

Physical properties of oil or medium, including relative density, maximum and minimum operating temperature, viscosity, vapor pressure, corrosion and toxicity, etc.

2. Whether the medium contains particles, particle diameter and content;

3. What is the percentage (volume) of the maximum gas content in the medium?

4. What is the required working head and flow;

5. Ambient temperature of the oil pump, distance from surrounding structures and explosion-proof grade.

For rotary vane vacuum pump, generally use the following two main parameters to express the performance, one is the pumping rate, the other is the residual pressure or limit vacuum.

1. Extraction rate

The extraction rate is the gas extracted from the air inlet of the pump in unit time at a certain pressure and temperature (the volume of gas absorbed by the vacuum pump from the air inlet at the residual pressure in unit time, that is, the production capacity of the vacuum pump (or flow rate Q), expressed as m ^ 3 /h or L/S).

2. Residual pressure or ultimate vacuum

Residual pressure or ultimate vacuum is the lowest absolute pressure the pump can achieve.

The minimum pressure (absolute) that the pump can achieve. With vacuum pump suction gas in an airtight container, regardless of the suction time how long, the pressure in the container is not infinitely reduce to zero, the absolute vacuum, this is because when the inlet pressure is lower than a certain value, after will vaporize liquid in the pump, pump cannot continue new gas suction, pressure of the container in this case, can no longer reduce, absolute pressure is called residual stress at this time.

What is the operation process of the vane vacuum pump in the oil depot?

1. Before starting the pump, open the irrigation valve, respectively fill water into the water supply tank and the vacuum pump until the overflow pipe overflows, and close the valve.

2. Close the valve connecting the vacuum tank pipeline and open the valve on the water ring pump, close the ball valve and start the vacuum pump.

3. After starting the pump, the vacuum pump will take out the gas in the vacuum tank and drain part of the gas and water in the pump into the water tank. After separating the air and water in the water tank, the air is discharged into the atmosphere by the exhaust pipe, and the water can be recycled through the valve.

4. Open the valve after the vacuum tank reaches a certain vacuum degree, and the vacuum pump will start to suck the air of the centrifugal pump system. When the oil interceptor has an oil inlet sound or a small amount of oil enters the vacuum tank, it means that the filling pump has finished, close the valve and stop the filling pump.

5, before stopping the pump should first close the water ring pump valve, and open the air valve, and then stop the pump to prevent the liquid in the pump from being sucked into the vacuum tank.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)