How to make the service life of vacuum pump longer

After using it for a period of time, we may suddenly find that the droplets at the outlet of the vacuum pump or the vacuum value can not go down, even the low boiling point solvent can not distill, what is the situation in the end?

One possibility is that the vacuum pump needs to replace the diaphragm.

Most manufacturers use PTFE diaphragm material, chemical corrosion resistance is very strong, aqua regia high temperature microwave digestion tank is just PTFE, so the service life of PTFE diaphragm is usually more than one year. But one year later, is it necessary to replace the diaphragm? It seems that some laboratories have used it for three years, and the diaphragm is still alive? There must be a secret. It’s not difficult. Let’s look around.

1.Observing signals

1) Vacuum pump outlet droplets

2) Buffer bottles in front of vacuum pump are liquid accumulation, yellowing, particulate matter, etc.

3) Vacuum value is unstable, good or bad, or vacuum leakage is reported.

2.Solutions

1) Once the above signal is found, immediately clean the buffer bottle and open the vacuum pump under no-load condition, empty to the pump outlet drip-free liquid.

2) Contact vendors or merchants after sales

3.Use of matching rotary evaporator

Make sure that the temperature difference between the heating pot and the condensation tube is at least 40-50 degrees C. If the temperature of the heating pot is 40 degree C, the condensation effect of tap water is not good, it is better to match the chiller, the temperature is between zero or – 10 degree C. The maximum recovery of evaporative solvents can reduce diaphragm effusion and prolong the service life of vacuum pumps. Secondly, it can minimize laboratory odor and provide a safe environment for laboratories. That’s what two birds with one stone say!

Set appropriate vacuum value and heating pot temperature, do not boil. If boiling, excessive steam can easily be pumped into the vacuum pump, resulting in unnecessary damage to the vacuum pump.

What if it boils?

1) Reduce the temperature of the heating pot

2) Higher Vacuum Value

3) Avoid evaporating solvent volume exceeding 1/2 of evaporating bottle volume

4) The IKA RV10 auto Pro rotary evaporator in our laboratory has Vent button, which can quickly deflate and solve sudden boiling.

What is the appropriate vacuum value?

First of all, we have to have a vacuum controller that can clearly display and adjust the vacuum value. Without a vacuum controller, the explosion boiling problem will be a hard wound!

Next, we can perform any of the following operations on the vacuum controller:

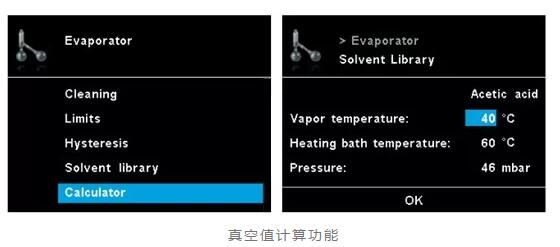

1) Call the solvent database, which has built-in distillation parameters – the vacuum value of a solvent at a specific heating pot temperature, direct distillation

2) The function of calculating vacuum value can calculate the best vacuum value according to different heating pot temperature. It’s really convenient.

3) Automatic boiling point identification function: no need to set the vacuum value, let the equipment find it by itself. Of course, different solvents, different temperatures to find the vacuum value are different, the task of finding the vacuum value is entirely left to the instrument.

4) The most pressing thing is to find out by oneself and gradually reduce the vacuum value from the atmospheric pressure down.

Good daily habits

Prevent trouble before it happens, develop good use habits, the service life of vacuum pumps is the most guaranteed!

1) At the end of the daily test, the vacuum pump should be emptied for 5 to 10 minutes to remove the accumulated fluid and particles in the vacuum pump.

2) Before entering the vacuum pump, the condensation tube or buffer bottle can be connected to protect the vacuum pump. The condensation tube is shown in the following figure.

3) According to different decompression experiments, proper decompression (with the help of vacuum controller) is needed, and it can not be directly pumped to the limit vacuum.

4) Decompression of heating steam, such as vacuum distillation, requires the recovery of cooling steam to reduce the amount of solvent directly pumped into the vacuum pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)