Rotary vane vacuum pump for vacuum coating

Rotary vane vacuum pump is an oil-sealed mechanical vacuum pump. Rotary vane vacuum pump has been widely used nowadays. Today we will talk about the application of rotary vane vacuum pump in vacuum membrane industry.

Vacuum aluminizing film is a kind of vacuum evaporation metal film. It is a process of melting and vaporizing aluminium under high vacuum (above 10mba) by heating with resistor, high frequency or electron beam, and forming composite film by attaching to the surface of film substrate. Plating a very thin layer of metal aluminium on the surface of plastic film or paper becomes aluminized film or aluminized paper.

Rotary vane vacuum pump is one of the most basic vacuum acquisition equipment in vacuum technology. Rotary vane vacuum pumps are mostly small and medium-sized pumps. There are two kinds of rotary vane vacuum pumps: single-stage rotary vane vacuum pump and double-stage rotary vane vacuum pump. The so-called two-stage structure is to connect two single-stage pumps in series. Generally, it is made into two stages to obtain higher vacuum.

Vacuum aluminized film for packaging characteristics:

1. Compared with aluminium foil, it greatly reduces the consumption of aluminium, saves energy and materials, and reduces costs. The thickness of composite aluminium foil is 7-9um, while the thickness of aluminium coating is about 400?(0.04um), the consumption of aluminium is about 1/200 of aluminium foil, and the production speed can be as high as 700m/min.

2. It has excellent flexibility and good toughness, seldom appears pinholes and cracks, no rubbing cracks, and improves the barrier of gas, steam, odor, light and so on.

3. It has excellent metallic luster and 92% light reflectivity, and can form color film through coating treatment. Its decoration effect is inferior to that of aluminium foil.

4. Partial aluminizing can be carried out by shielding or elution to obtain any pattern or transparent window, and the contents of the package can be seen.

5. Aluminum coating has good conductivity and can eliminate electrostatic effect. Especially when packing powder products, it will not pollute the sealing part and ensure the sealing performance of packaging.

6. It has good adaptability to post-processing such as printing and compounding.

As the rotary vane vacuum pump makes the aluminized film become a new type of composite film with excellent performance and beautiful economy, it has replaced the aluminium foil composite material in many aspects. It is mainly used for packaging flavor food, daily necessities, agricultural products, pharmaceuticals, cosmetics and cigarettes.

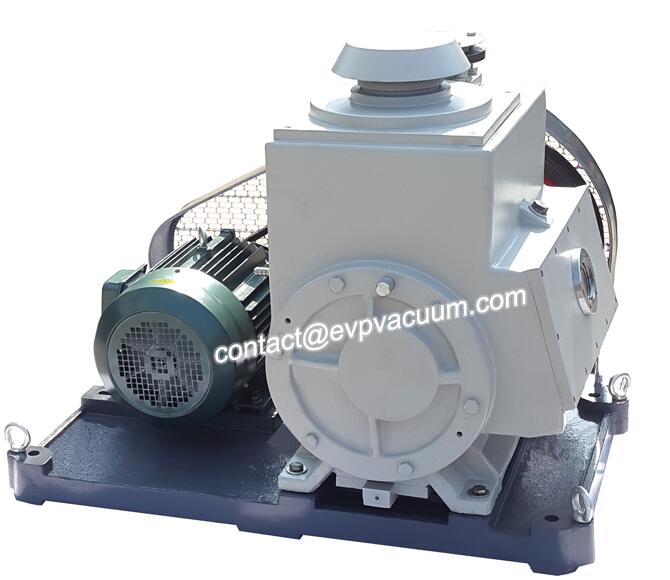

2X-A Rotary Vane Vacuum Pump

| 2X-4A | 2X-8A | 2X-15A | 2X-30A | 2X-70A | 2X-100A | |||

| Pumping speed(L/s) | 4 | 8 | 15 | 30 | 70 | 100 | ||

| Ultimate pressure(Pa) | Partial pressure | 6×10ˉ²(5×10-4Torr) | ||||||

| Total pressure | 2.66(2×10-2 Torr) | |||||||

| Rotary speed(r/min) | 450 | 320 | 320 | 450 | 420 | 360 | ||

| Motor power(Kw) | 0.55 | 1.1 | 2.2 | 3 | 5.5 | 7.5 | ||

| Working voltage(v) | 380 | 380 | 380 | 380 | 380 | 380 | ||

| Cooling Mode | Natural cooling | Water cooling | ||||||

| InletDiam(mm) | I.D. | 25 | 40 | 50 | 65 | 80 | 80 | |

| O.D. | 30 | 50 | 80 | 85 | 100 | 125 | ||

| Dimensions(mm) | Length | 540 | 790 | 790 | 810 | 910 | 1130 | |

| Width | 335 | 430 | 530 | 480 | 650 | 740 | ||

| Height | 380 | 540 | 540 | 560 | 700 | 690 | ||

| Oil capacity(L) | 1.0 | 2.0 | 2.8 | 3.0 | 4.2 | 5 | ||

| Recommend solenoid valve | DDC-JQ25 | DDC-JQ40 | DDC-JQ40 | DDC-JQ65 | DDC-JQ80 | |||

| Noise (dB A) | 65 | 70 | 70 | 70 | 75 | 90 | ||

| Weight(kg) | 60 | 158 | 202 | 230 | 480 | 560 | ||