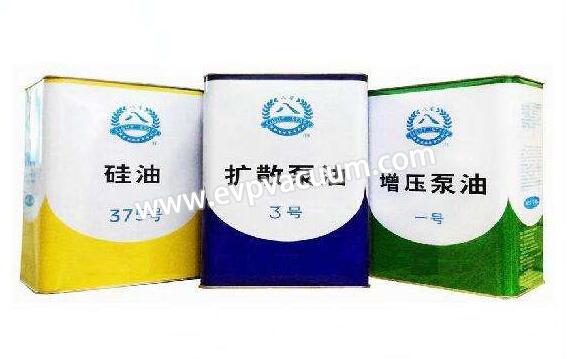

Booster pump oil

Booster pump oil of features and uses

The booster pump oil is made from paraffin base oil, which is first cut into narrow fraction by molecular distillation after solvent assisted dewaxing and deep refining, and then by adsorption refining and vacuum degassing. It is suitable for domestic and foreign oil booster pumps.

Booster pump oil is the working fluid of various booster pumps. It is suitable for vacuum smelting, plastic continuous metal spraying, vacuum distillation and low density wind tunnel equipment.

A large number of tests have proved that the performance of No.1 booster pump oil is far better than that of other brands of similar pump oil, and it is the best gas booster pump oil. The use of No.1 can reduce the times of replacing and replenishing pump oil, shorten the cleaning cycle, reduce the maintenance cost and maintenance times. It is widely used in the field of industrial vacuum, such as vacuum metallurgy, vacuum distillation, vacuum metal coating and vacuum filling. The reliability of No.1 is recognized by engineers around the world, and some steam booster pump manufacturers even specify the use of No.1 pump oil as a prerequisite for their warranty.

The outstanding features of No.1 are to speed up the vacuum pumping speed, prolong the service life, convenient maintenance and reduce the number of pump oil replenishment. By specially designed anti-oxidation, it will not be affected by the small amount of water vapor in the gas to be pumped. In order to obtain vacuum faster in industry, the booster pump must run at high speed. Therefore, the specially designed booster pump can obtain high speed, make the vacuum pump switch faster and shorten the time of vacuum pumping. With excellent ventilation / pressure performance, the pump oil is still clean at 1000 rpm, and there is no tar deposit in the pump nozzle and baffle, which ensures easier and faster maintenance of the vacuum pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)