ATEX blower for biogas plant

Provide biogas production solutions

In biogas production, storage facilities that can safely store and “store” the gas are needed.

Pressure control of biogas plant

ATEX blowers are required in the design of biogas storage facilities.

Storage of biogas

Biogas comes from biomass. Biomass includes renewable raw materials, as well as biological wastes, faeces and sludge.

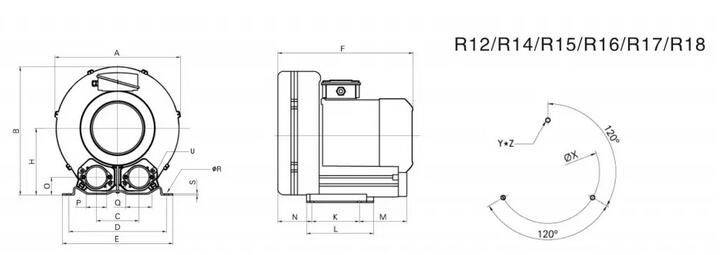

ATEX blower size

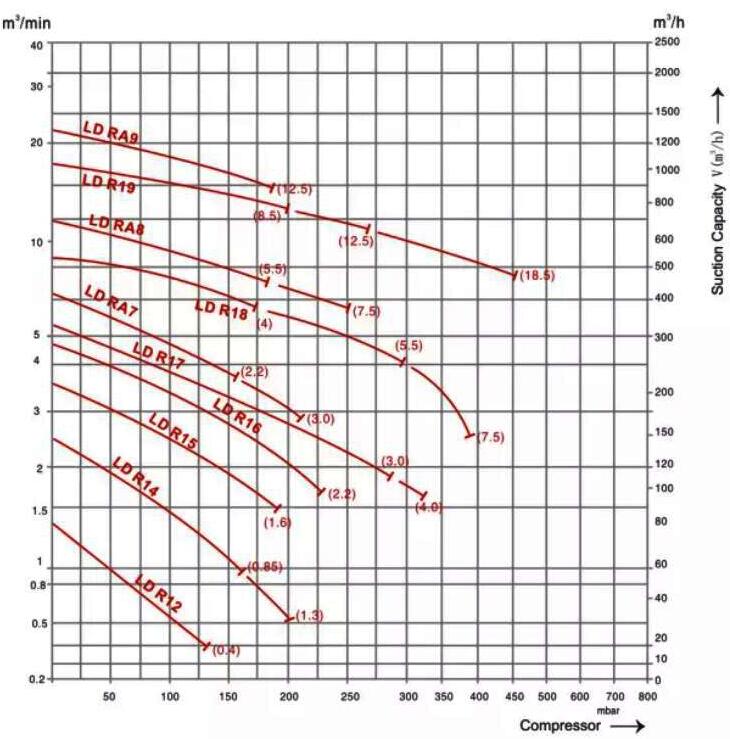

ATEX blower performance curve

Its actual production occurs through the fermentation of biomass. The resulting product is a flammable gas (methane). The energy can come from the burning of methane in cogeneration plants. During fermentation in a biogas storage facility, the volume contained in it changes. Therefore, the storage facility has been equipped with a flexible inflatable membrane cover and a double membrane. The inner lining is gas-tight and expands or contracts during methane production. The outer membrane is placed on top of the membrane to protect against rain, wind and other weather conditions. The fan and ATEX PCS keep the air cushion between the two membranes constant. Methane can escape through leaks in the membrane and become an explosive methane-air mixture.

ATEX pressure control system

The challenge for the experts was to develop a system that would keep the air pressure in the mattress constant while still fitting into the ATEX area. Due to this requirement, ATEX pressure control system (or ATEX PCS for short) was developed. Primary pressure is detected using a pressure sensor and transmitted to PCS. PCS then adjusts the ATEX auxiliary blower to maintain the predetermined pressure at all times.

PCS is located outside the ATEX area. Pressure sensors and fans are installed directly on the biogas storage facility. All components in the ATEX area comply with THE ATEX certification of EX II 2G C T3. The entire system can be equipped with or without a stainless steel suction strainer. The maximum pressure may be set between 50 and 2,500 Pa, depending on the blower. The maximum air output of the blower is 600 to 2,700m/h.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)