Rotary vane vacuum pump in petrochemical industry

Application of rotary vane vacuum pump in petrochemical industry. With the improvement of the quality requirements of various industries, the defects of products will be magnified and the tolerance will be lower and lower. This is especially true of pharmaceutical products. Therefore, in vacuum distillation, in order to improve the distillation efficiency and the quality of distilled products, more and more pharmaceutical enterprises pay more attention to the improvement of product quality in the process of vacuum pump selection, instead of focusing solely on pumping speed and vacuum degree. At present, more and more enterprises prefer to choose the special vacuum pump for vacuum distillation, from chemical enterprises to pharmaceutical enterprises.

Vacuum distillation (also known as vacuum distillation) is an important method for separating and purifying compounds. It is especially suitable for the separation and purification of compounds with high boiling point and those that have been decomposed, oxidized or polymerized before reaching the boiling point in atmospheric distillation. Vacuum distillation is a vacuum process often used in the production of various chemical pharmaceuticals and petrochemical industry.

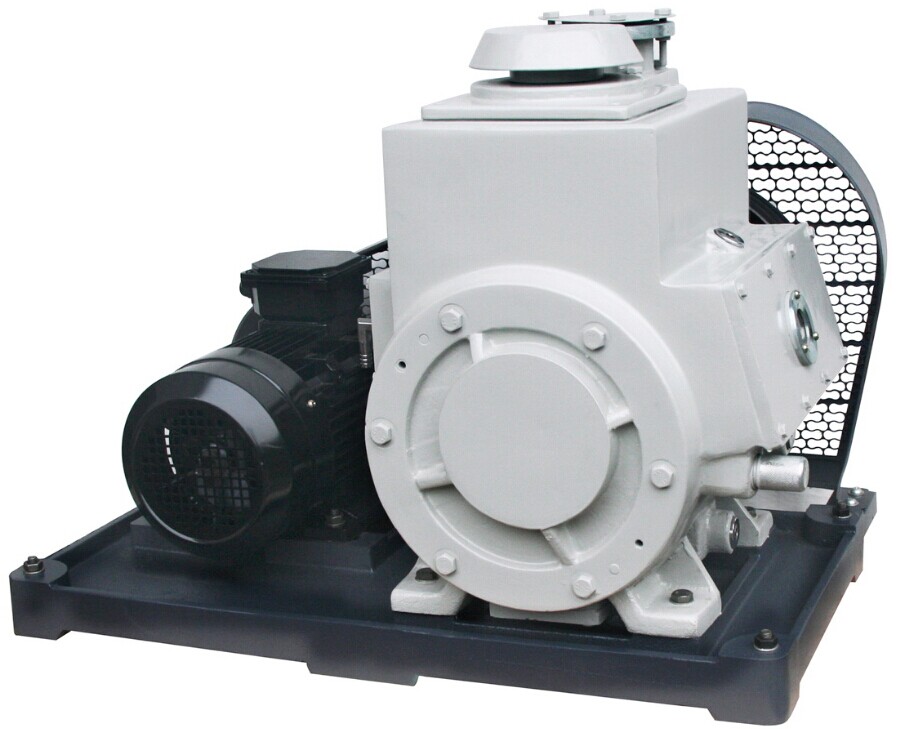

2X-A Rotary Vane Vacuum Pump

What is the role of rotary vane vacuum pump in petrochemical industry?

The working range of rotary vane vacuum pump is from atmospheric pressure to about 1 Pa limit vacuum. It has a wide range of pumping speed. Under low vacuum, single pump can achieve high pumping speed. Its structure is simple and reliable, and its maintenance and operation are convenient. On the other hand, the inherent cleanliness of rotary vane vacuum pump does not need other media to participate in the extraction process, and does not need to worry about reflux pollution media, and can be combined with Roots and other groups to form a clean, high vacuum, high pumping speed and large dry vacuum unit products.

In the fields of food, fine chemical industry, pharmaceutical semiconductor, etc., which have strong demand for clean vacuum and various recycling fields, these characteristics can effectively improve the production efficiency of enterprises, greatly simplify the vacuum system operation process and various supporting links, and improve product quality, so they are favored by enterprises.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)