Brand: EVP

Classification: Vacuum Pump

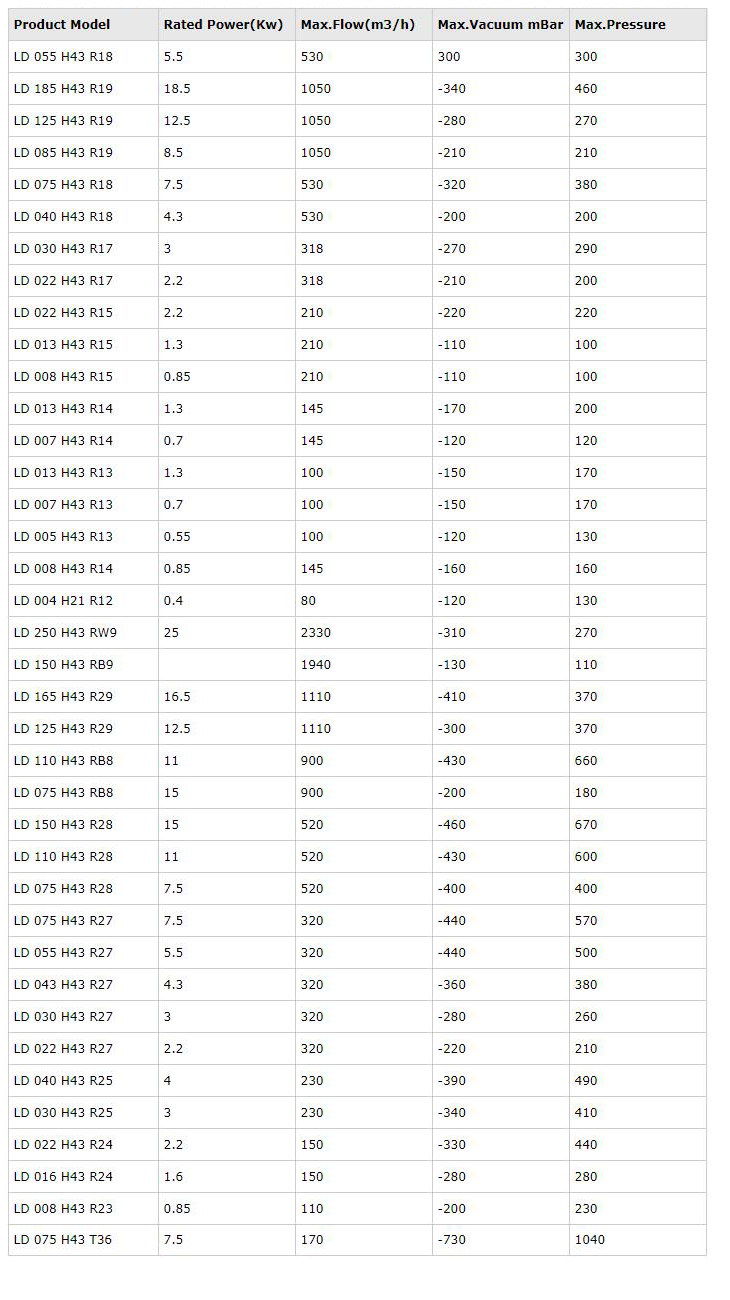

SUCTION CAPACITY: 80M3/H TO 2330M3/H

VACUUM RANGE: TO -730 MBAR

Availability : In Stock

Side channel blowers are machines that are used to move air and increase pressure due to a rotating impeller inside a toroidal channel. This gradually increases the energy. The term "side channel" comes from the circumferential position of the annular channel compared to the impeller.

EVP Side Channel Blower Features:

1. vacuum and blowing fuction can be used at the same time.

can be running at 50Hz and 60Hz at the same time.

2. oil-free type ring blower,make sure oulgoing air is totally pure.

3. high pressure,large air flow ,low noise and light weight.The space between impeller and casing;

rotor and cover is very tiny,make sure the pressure will be higher.

4. Impellers are special designed,in order to make itself high precision,durable,large air flow and longer working life.

5. Reliable quality,LD series ring blower can be working at above 5000M sea leval and it can also bear high temperature and cold temperature.

6. Maintaince free design within 12 months.

7. CE,CCC,certificate

EVP Side Channel Blower Advantages:

Quiet

Equipped with low-noise, high-efficiency IP54 induction motor and specially designed mufflers, all blower series feature quiet operation.

Mechanism Features

Three-dimensional blower impellers rotation enables the air between blades to accelerate along the radius direction. The air is forced to return back to the base of the impeller due to pressure difference, throwing it outward and forward through a spiral path. This action is repeated many times and causes the air to gain pressure, until it reaches the outlet port of the housing. The air is expelled from the impeller and discharged from the blower through the outlet.

Longer operation life

External bearing design allows bearings to operate in low temperature, features quick heat dissipation and uniform loading capacity. Lubrication oil is more durable and makes maintenance an easy job.

Installation Easy

The base of all blower models is made with flexible steel plates that feature shock absorption. Fastened with screws. The bases can also be fixed through the screw holes on the front cover, enabling either vertical or horizontal installation as required.

Long time operation

Made of aluminium alloy, all the TURBO blowers are lightweight and excellent in heat dissipation, thus allowing long time operation even under ambient temperatures reaching 40oC; insulation class F and H ensures better reliability.

Fully closed unit

Multi-layer shaft seals are used to thoroughly separate motor coil from blower body, ensures excellent performance and prevents motor from damage.

The use of Turbo side channel blowers is common in machine-building as high pressure ventilator, vacuum pump, air pump, booster, low pressure compressor and oil-free compressor. The applications are unlimited like aireating, dust cleaning, vacuum lifting, vacuum tables, blowing off, pneumatic transport, cooling and vacuum molding.

Applications:

1. Pneumatic conveying systems

2. Lifting and holding of parts by vacuum

3. Packing machines

4. Aeration of sewage-treatment plants

5. Filling of bags / bottles / hoppers

6. Soil remediatiom

7. Thermoforming

8. Sorting / enveloping of letters

9. Food-processing

10. Laser printers

11. Dental suction equipments

12. Paper processing

13. Printers / copiers

14. Textile machines

15. Aeration of fish ponds

16. Gas analysis

17. Swimming pool equipment / whirlpools

If possible, kindly suggest please your working industry/process, working pressure, working medium, etc. Given detailed request helps to gain better-matched customized solution. Thanks for your patience.

your request will be responsed within 3 hours, kindly pay attention to your email please.