Steam Jet Pump Vacuum System

Our steam injection system has reliable performance and low maintenance requirements.

Application

Jet vacuum system is used to create and maintain vacuum in polyester and nylon production equipment.

Steam Ejector

Steam ejector is a kind of vacuum equipment, which is the application of jet technology in the field of heat transfer. The steam ejector has the characteristics of simple structure, no moving parts, stable and reliable operation, large pumping capacity, and can extract water vapor, dust, flammable, explosive and corrosive gases.

- Under any working condition, it has high reliability and stability;

- No mechanical moving parts, almost no maintenance;

- Large pumping speed, up to several hundred thousand M3 / h or even several million m3/h;

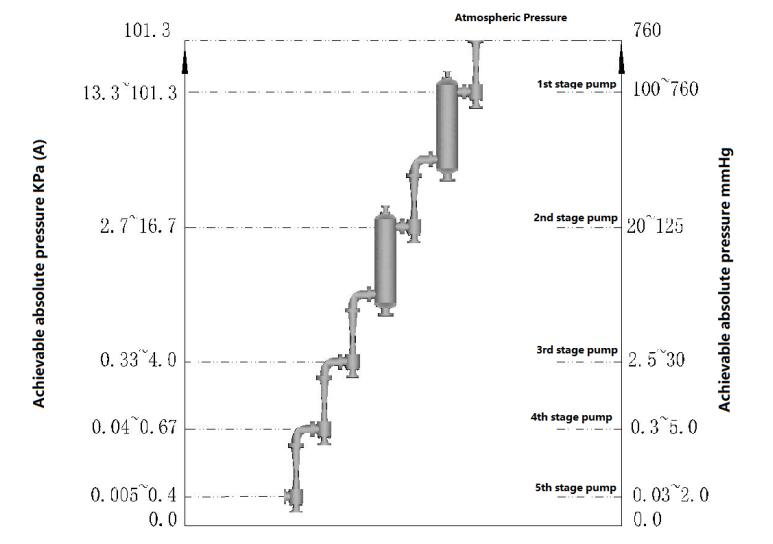

- The vacuum system of steam ejector is generally 2 to 5 stages, and there are also 6 stages. The low pressure can be achieved by multi-stage combination, and the limit pressure of 0.67pa can be achieved by 6-stage combination;

- According to different working conditions, various metal materials (stainless steel) and non-metal materials (graphite) can be selected;

- By matching with mechanical vacuum pump (liquid ring vacuum pump), low energy consumption and stable operation can be achieved.

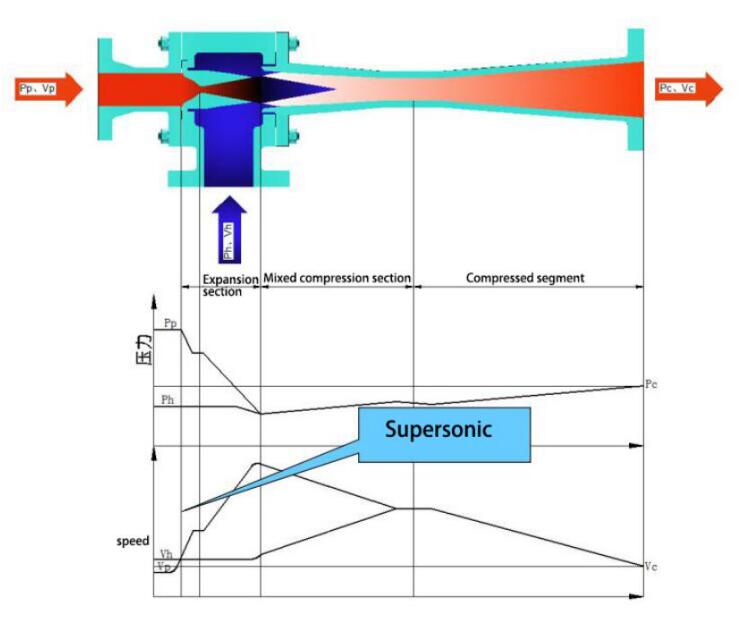

Working principle: the high-pressure power steam enters the suction chamber at several times the speed of sound through the Laval nozzle, forming a low-pressure area in the suction chamber, and the low-pressure suction fluid is carried into the suction chamber by the high-pressure power steam; in the mixing section of the diffuser, the power steam decelerates continuously, and the extracted gas accelerates continuously to exchange momentum and energy and mix gradually; In the throat of the diffuser, the power steam and the extracted gas are completely mixed evenly, and the speed reaches the same; in the diffuser section, the speed gradually decreases, and the pressure gradually increases, and the kinetic energy is converted into enough pressure energy to achieve the outlet pressure discharge.

Suction Range: The steam ejector is customized according to different working conditions, with an extraction volume of 0 to several hundred thousand cubic meters.

Material: Carbon steel, stainless steel, graphite and other non-metallic materials can be selected according to different working conditions.

Steam Ejector Vacuum System

The steam injection system is composed of steam ejector, condenser and valve fittings. General steam injection system mainly includes: direct condensation steam injection system and indirect condensation steam injection system.

Operation mode

Jet vacuum pumps are usually driven by steam. Steam is easy to obtain in industry and has been proved to be a good power medium. When the steam in the jet vacuum pump condenses, the condensate must be regarded as waste liquid in some cases.

If the product steam generated in the production process is used as the power medium of the jet pump, this situation can be avoided. The power steam condensate can be further used in production or re evaporated and used as power medium again. The product steam driven jet pump is also used under the condition that no water can enter into the system.

Advantage

- No moving parts

- No maintenance required

- It can be installed in almost all cases

- It can be put into using quickly and easily

- There is almost no life limit if the right material is chosen

- It can be made of various materials

- Low procurement cost

The function of product steam driven jet vacuum pump is no different from that of steam driven jet vacuum pump, so it provides the same basic advantages. In addition, the energy consumption requirement is lower than that of steam driven jet vacuum pump to a certain extent, because the evaporation of organic steam requires less heat.

Learn More : Steam Jet Vacuum Pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)