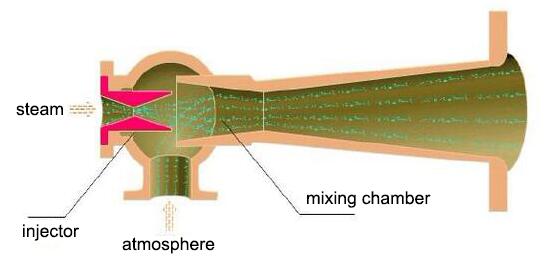

Steam jet vacuum pump

Steam jet vacuum pump of working principle and influencing factors

The vacuum technology used more and more widely, used in petroleum, chemical, pharmaceutical, metallurgical industries such as distillation, vacuum evaporation, vacuum concentration, crystallization, drying and dehydration, sublimation, absorption and chemical reaction process such as vacuum conveying material, all kinds of processing technology after the application of vacuum technology can effectively accelerate the reaction speed, saving energy and reducing consumption, improve product quality, increase enterprise economic benefits finally. Steam jet vacuum pump has the advantages of high vacuum, low energy consumption, stable operation, no mechanical friction, long service life and equipment safety. The steam jet vacuum pump is the first choice in the high vacuum system.

The main factors affecting the steam jet vacuum pump are: steam pressure, steam dryness and circulating cooling water.

If the steam pressure is low or uneven, the vacuum capacity of vacuum pump will be reduced. On the contrary, if the steam pressure is too high, the vacuum degree of vacuum pump will not be increased. Therefore, the steam pressure should be between 1.1Mpa and 1.2Mpa.

Steam contains too much water, it will cause vacuum fluctuation, or even can not pump vacuum, generally in the bubble before the installation of a soda separator, in order to ensure the supply of steam drying to meet the required requirements, at the same time, the steam pipeline for heat preservation, the best working steam temperature in 5℃ ~ 10℃.

If the supply of circulating cooling water is insufficient, the condenser will heat up, leading to the increase of airflow sound, the rapid decrease of vacuum degree, and even lead to the backflow of steam exhaust pipe. But the water supply should not be too large, too large so that condensed water form water droplets are inhaled by the lower level, resulting in the vacuum pump can not work normally. The water supply needs to be only slightly larger than it actually is.

The quality of cooling water also affects the vacuum pumping capacity. Poor water quality and high hardness can easily lead to condenser scaling and blockage, thus affecting heat exchange performance, making steam difficult to condensate, and finally affecting vacuum degree.

Steam jet vacuum pump installation and maintenance need to pay attention to matters

The steam ejector vacuum pump can be installed outdoors in the open air. When installed, the internal connection pipe is installed and is used as a quick drain, so the whole unit can drain quickly during shutdown or in freezing weather.

The steam jet vacuum pump must have enough static pressure, the pump packing box must have water seal. Install a check valve in the pump drain to prevent intermittent or pulsed air backflow. The pipeline will be closed loop, install appropriate loop long channel, it is best to install a water discharge pipe in the lowest position of each loop pipe, so as to effectively balance the pressure difference between the condensers, but also as the outlet for cleaning the condenser.

Installing a steam jet vacuum pump line, must pay attention to keep to the steam nozzle as far as possible dry, warm steam nozzle will not only corrosion, will soon spread, which seriously affect the function of the small nozzle, so installation of the pipe to the shorter, the better, received steam from the steam jet vacuum pump tube to pick out from above steam pipe, at the same time should also be long-term stay dry separator.

Vacuum pump vacuum degree requirements are relatively high, especially the pump small nozzle diameter, so must check installed in the steam filter and jet pump steam nozzle between the pipe is clean. To facilitate the removal of the nozzle, the steam jet pump can be installed on an inlet stingy box, and a probe can be used to directly check whether the nozzle access. In order not to affect the free flow section area of steam, steam gaskets should not be placed off-center.

When the steam jet vacuum pump is used for maintenance, first of all, regularly check whether the packing wear, need to be replaced. If the packing is worn out and cannot guarantee the required seal, the packing should be replaced in time, and the packing should not be pressed too tight, the normal pressing is to ensure that no water dripping out, it should be noted that the amount should not be too much, in order to ensure that no water dripping out, the amount is not too much, use oil-soaked asbestos rope as the packing.

The actual operating temperature of the vacuum pump shall not exceed 70℃, and the bearing shall be buttered to 2/3 of the whole space, and shall not be filled. The bearings used should be loaded with oil every three to four months. The bearings should be cleaned at least once a year, and all the lubricating oil should be changed during cleaning

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)