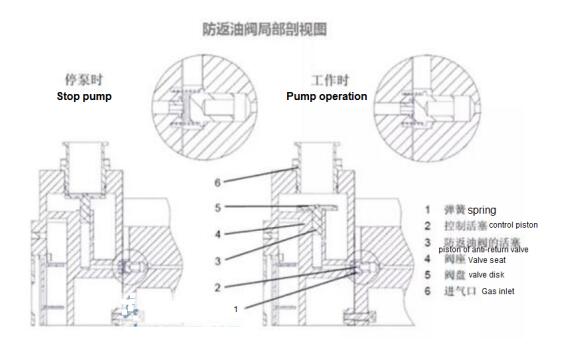

The principle of anti-return device for vacuum pump

Two-stage rotary vane vacuum pump is belonging to an oil-sealed vacuum pump. In order to prevent the vacuum pump oil from returning to the pumped container when the pump is stopped, the built-in stop pump anti-return device is very important.

Preventing pump back oil is usually achieved by a combination of gas path and oil path. Common methods are:

1. Set the pump stop anti-return device on the intake passage

2. There is a pump stop control anti-return device on the oil road.

3, the above two combinations

During the operation of the 2XZ series two-stage rotary vane pump, the control piston is kept sealed against the spring under the action of oil pressure. The valve disc of the anti-backup valve is kept in a lower position due to its own weight (valve open). After the pump is stopped, the oil pressure drops and the spring will control the piston to the top. This creates a path between the fuel tank and the piston of the anti-backup valve.

tags: Rotary vane vacuum pump, Two stage rotary vane vacuum pump

Edited by Catherine Qin / EVP Vacuum Solution