Vacuum pump and air ejector vacumm system advantage

It often appear big noise and impeller cavitation problems during water ring vacuum pump running. Usually the reason is vacuum pump inlet pressure is too low, then resulting in rupture of the bubble. It can lead to vacuum pump’s rotor rupture and scrap when this situation become serious. When the volume of vacuum pump have a little big, the above problems are especially serious. Facts show that these questions can be solved effectively when vacuum pump add the air ejector.

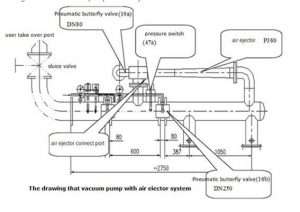

Please reference the picture as follow:

Air ejector has the two points function as following :

(1)Expand the working scope of the vacuum pump and prevent cavitation

(2)Increase the suction capacity of the vacuum pump. The fact shows that after the installation of an air ejector, the noise of the vacuum pump is become reducing obviously and it has little effect on the vacuum of the system. And the overall performance of the vacuum pump is more better than before when the ambient temperature become low in winter.

The diagram about vacuum pump with air ejector as follows:

The effect of energy conservation :

Making vacuum pump together with air ejector, this design mainly function is reduce the times that replace of the rotor. Reducing the maintenance cost of vacuum pump . In addition, the vacuum pump motor’s current will have some rise after the air ejector running (about 15A), but this part cost is more less than reduced maintenance costs. The technology can effectively solve the problem of ultimate vacuum caused by the high water temperature of the vacuum pump, so some system can also obtain a certain energy-saving benefit in vacuum improved.

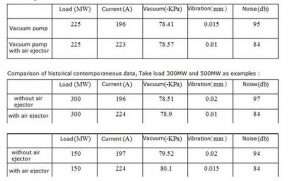

The data comparison that before and after add the air ejector:

After the vacuum pump is installed with the air ejector, it also can maintain the vacuum degree. However, the gas passing through the vacuum pump is the system intake and drive gas (the gas from the separator). After the mixture gas enters the vacuum pump, the running vacuum of the vacuum pump is reduced which to eliminate cavitation , Vibration and noise. Through the site noise test, the noise was reduced from 97db (before the renovation) to 84db (after the renovation). On the other hand, the system or vacuum pump’s vacuum close to 5Kpa before the installation of the air ejector, the system or vacuum pump’s vacuum close to 13Kpa after the installation of the air ejector. Vacuum pump’s shaft power (at 13Kpa) is higher than 5Kpa, so it caused the current increase.

The testing data as follow:

It can be seen from the above table that after add the air ejector, the vacuum system increases around 0.5 KPa. However, taking into account the leak detection and repair of the vacuum system after the system is overhauled, it can be neglected. Current increased from 197A to 224A, it’s rise about 13% and it have a little increase in plant electricity. However, the reduced cavitation can increase the overall life of the vacuum pump, it greatly reducing the replacement of spare parts (It more than cost 100,000 RMB for replacing a rotor impeller). In addition, the noise and vibration problems are solved, especially the noise elimination is very obvious and the noise is controlled eligibility range. Vibration damage of thermal instrumentation also will be reduced and equipment reliability is guaranteed, the reduction of manpower and material resources have been reflected, the overall economy is still quite considerable contrast.

Suggest:

(1)Double suction vacuum pump is preferred; single suction vacuum pump should be equipped with air ejector

(2)The vacuum pump with low-pressure condenser should be equipped with air ejector

(3)At the high temperatures, the air ejector can be evacuated according to site situation

Tags : vacuum pump, Liquid ring pump, air ejector, vacuum system

Edited by Jinny Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)