Difference Between Dry Screw Pump & Oil Lubricated Screw Pump

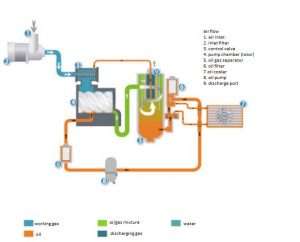

Oil lubricated rotate screw vacuum pump

As per figure (1), oil lubricated screw pump has oil filled on its rotor chamber, working as lubricant, sealant and coolant. This type of screw pump can achieve high capacity (according to one famous brand, the capacity range can be 400~5004m³/hr), but its ultimate vacuum is relative low, merely at 0.33mbar. Because of oil on rotor chamber, users cannot gain absolute clean /oil free vacuum. Herewith, it is usually used for rough vacuum evacuating which has no request on clean vacuum, suitable for industry like electronics, woodworking, plastics, printing&paper, etc. It’s not suggested to evacuate gas with high contenct of oxygen, being corrosive to ferrous metal, chemically active with sealing oil, and gas with dust or particles.

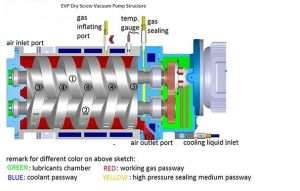

Dry screw vacuum pump

Refer figure (2), EVP dry screw vacuum pump have no oil/lubricant on its rotor chamber. One of big advantage of this pump is to obtain absolute clean/oil free vacuum. Due to its structure, it can evacuate explosive or flammable gas, gas with abundant vapor or dust, as well as corrosive gas after special surface process on its chamber. Hence it has wide application. Besides, compared with oil lubricated screw pump, the dry screw pump can achieve higher vacuum, its ultimate vacuum at 0.02/0.01mbar.

Among dry screw vacuum pump, it can be divided into two type according to rotor structure, constant pitch screw pump and variable pitch screw pump. The variable pitch pump is updated basing on constant pitch to achieve better performance. Followed are advantage and shortcoming of EVP variable pitch screw pump:

1)pump body with low temperature in working

Gas will obtain high pressure and temperature while in transmitting and compressing. Due to variable pitch screw pump has smaller transmitting and discharge chamber(refer figure 4), the gas is naturally compressed, less heat will be created. This structure lowered the back flow rate of high pressure/temperature gas, so that the high temperature is remained at discharge port end, where the coolant is supplied. Herewith, the gas and rotor temperature is cooled quickly. The pump can remain low temperature in whole working process, to gain pleasant working environment.

2)low noise

Because of low gas backflow rate, less noise/sould will be created on pump chamber.

3)energy saving

Since gas is naturally compressed by rotor structure, compared with constant pitch screw pump, the power consumption of variable pitch pump is less than 30%. For example, the EVP LG70 at 70L/s, it’s 7.5Kw for constant pitch screw pump, but 5.5Kw for variable pitch screw pump.

4)suitable for easy indurated or liquefied gas

Some gas would be easy indurated or liquefied when having physical or chemical change. Because variable pitch screw pump compress gas by its own structure, it’s not suggested to evacuate such gas.

In reverse, the constant pitch screw pump has less compressing ration on passing gas, it is recommended to evacuate such gas. Because its gass passing way is shorter and simpler, the gas pass through the rotor chamber quicker. This structure has higher power consumption for decreased compression ratio, but it had won good comments on semiconductor industry.

Except for single screw pump unit, EVP is also good at providing related system according your working process. Below is photo of recent elivery. If any request, welcome to contact us. We would be pleased to be at your service.

Tag:screw vacuum pump , roots-screw system

Edited by:Shell Hu / EVP VACUUM SOLUTION

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)