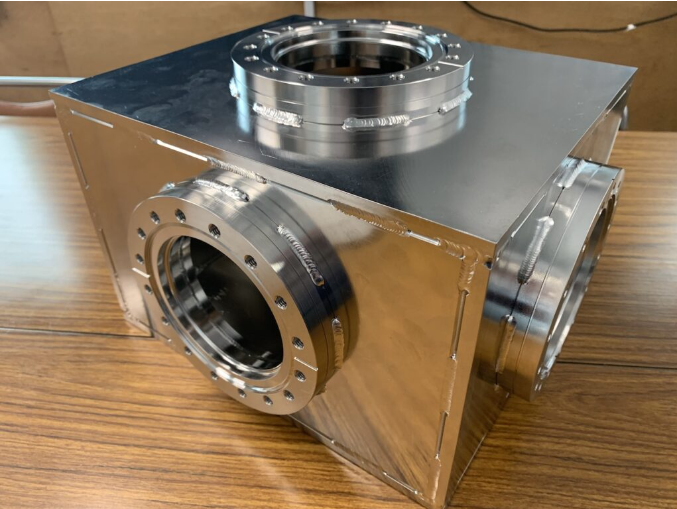

Vacuum chamber for semiconductor equipment

Making Semiconductor Equipment More Stable — Analysis of Vacuum Chamber Manufacturing

Semiconductor equipment plays a crucial role in modern technology, and one of the key factors in manufacturing semiconductor equipment is the vacuum chamber. This article will comprehensively analyze the manufacturing process of vacuum chambers.

What is a vacuum chamber?

A vacuum chamber refers to a vacuum environment container used in semiconductor equipment to manufacture semiconductor chips, whose main function is to provide a stable vacuum environment for semiconductor processing. In semiconductor manufacturing, many processes require vacuum or extremely low pressure environments, as impurities such as oxygen, water vapor, and dust in the air can have a negative impact on semiconductor devices. Therefore, vacuum chambers are widely used in semiconductor equipment, such as lithography machines, thin film deposition equipment, ion implantation equipment, etc. In these devices, vacuum chambers play a crucial role, and their stability and precision have a significant impact on the manufacturing and performance of semiconductor devices.

The manufacturing process of vacuum chambers

1. Design and Manufacturing

The manufacturing of vacuum chambers is a highly technical process that requires strict design and manufacturing. During the manufacturing process, factors such as material selection, cavity size, and vacuum requirements need to be considered. Different materials have different characteristics, and when selecting vacuum chamber materials, it is necessary to consider their physical and chemical properties, such as thermal expansion coefficient, thermal conductivity, chemical stability, and other factors. The commonly used materials include stainless steel, aluminum alloy, titanium alloy, etc. These materials have good mechanical properties, corrosion resistance, and thermal conductivity, and are not prone to oxidation or gas release in vacuum environments. For semiconductor devices with special requirements, such as high-frequency microwave devices and optoelectronic devices, ceramic or semiconductor materials can also be selected.

2. Cleaning and Handling

Before manufacturing a vacuum chamber, it is necessary to clean and treat the material to ensure the cleanliness and flatness of the chamber surface. Special solutions and tools are required during cleaning and processing.

3. Processing technology

In terms of processing technology, attention should be paid to the surface treatment of the cavity to avoid defects that may affect its performance. Mechanical processing, electrical discharge machining, laser processing, chemical corrosion, and other methods are usually used to treat the surface. In addition, to avoid impurity contamination, strict cleaning measures need to be taken during the processing.

4. Welding and assembly

After cleaning and processing, each part needs to be welded and assembled. During the welding and assembly process, attention should be paid to temperature and pressure control to avoid material deformation and air leakage.

5. Inspection and testing

After manufacturing is completed, it is necessary to inspect and test the vacuum chamber. The main detection methods include visual inspection, leakage rate testing, internal cleanliness testing, etc. The inspection items include vacuum degree, sealing, leakage rate, etc. High precision testing equipment and instruments are required during the testing process.

Creating a stable vacuum chamber is an important step in the manufacturing process of semiconductor equipment. Only through scientific design, meticulous manufacturing, strict cleaning and processing, precise welding and assembly, as well as accurate inspection and testing, can the quality and stability of semiconductor equipment be guaranteed.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)