Cryogenic Pump in Industry of Types and Applications

Cryogenic pumps are mainly divided into the following categories

Cryogenic condenser pump: Uses low-temperature surface condensation of gas molecules to achieve pumping, suitable for high vacuum environments.

Cryogenic adsorption pump: Using adsorbents (such as activated carbon) to adsorb gas molecules.

Cryogenic pump: Utilizing a refrigeration mechanism for cooling, suitable for high cleanliness and pollution-free environments.

Cryogenic pumps of specific uses

Refrigeration industry: Low temperature pumps are used in refrigeration units, ice makers, air conditioners, and other equipment to circulate condensers and evaporators, ensuring cooling effectiveness.

Medical industry: used for the cryopreservation and transportation of frozen storage equipment such as blood, vaccines, drugs, and human tissues.

Semiconductor industry: used for process applications in high vacuum environments to reduce the velocity of gas molecules and ensure the stability of semiconductor processes.

Aerospace: Widely used in spacecraft fuel delivery systems, propellant delivery systems, etc.

Chemical industry: Provide a stable low-temperature environment to ensure the smooth progress of chemical reactions.

Pharmaceutical industry: Ensure the storage and production of drugs under specific low-temperature conditions.

Food industry: Extend the shelf life of food and maintain its nutritional content.

Research experiment: Provide high vacuum environment in fields such as semiconductor manufacturing and nanomaterial research to ensure the accuracy of experimental results.

Electronic industry and optical instrument manufacturing: improving product quality and production efficiency.

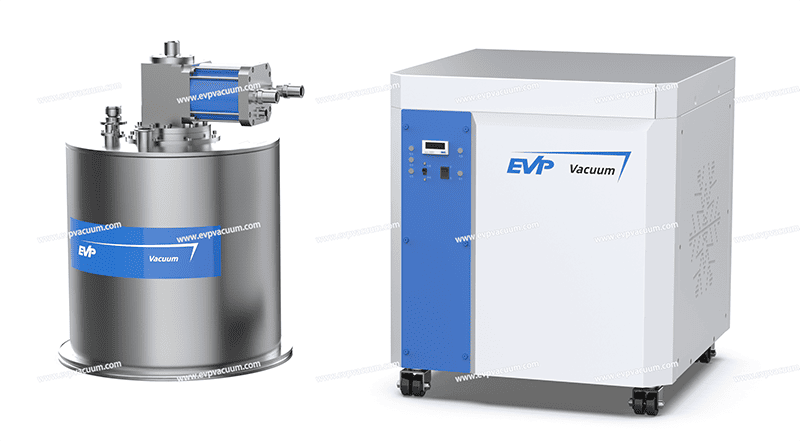

Vacuum equipment: Used in conjunction with other vacuum equipment to form a complete vacuum system.

Cryogenic pump of working principle

A cryogenic pump utilizes a low-temperature surface below 20K to condense gas molecules, and removes various gases through the action of a bipolar cold head, achieving an ultra-high vacuum state. Its working principle includes low-temperature condensation and low-temperature adsorption. The former achieves gas extraction by condensing gas molecules, while the latter adsorbs gas molecules through adsorbents.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)