Vacuum chamber surface treatment method

Vacuum technology plays an increasingly important role in modern industrial production and scientific research. As the core component of the vacuum system, the performance of the vacuum chamber directly affects the operation of the entire system. The surface state of the vacuum chamber has a decisive influence on key indicators such as vacuum degree, gas release rate, corrosion resistance and service life. This paper aims to systematically explore the key technologies and applications of vacuum chamber surface treatment, analyze the advantages and disadvantages of different treatment methods, summarize the development trend of surface treatment technology, and provide technical reference for the design, manufacture and use of vacuum chambers.

Most vacuum valves and chambers are made of stainless steel and aluminum alloy. There are four main purposes for surface treatment:

1.Prevent the base material from releasing gas and affecting the vacuum degree;

2.Prevent loose sealing and affecting the vacuum degree;

3.Prevent the process medium from corroding the inner surface;

4.Prevent the process medium from adsorbing the inner surface and causing blockage.

Several common vacuum product surface treatment technologies can be divided into the following categories:

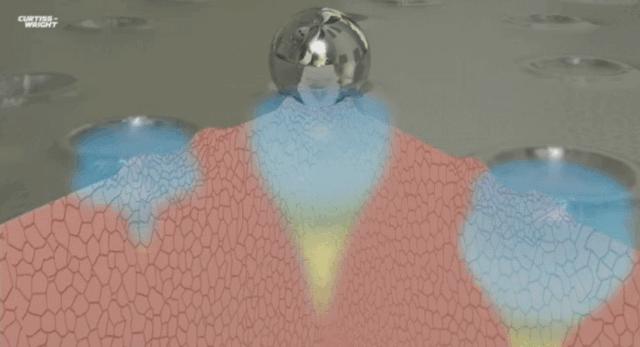

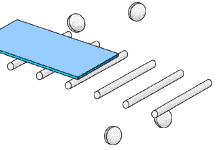

Shot Peening

Shot peening is a cold processing process that uses pellets to bombard the workpiece surface and implant residual compressive stress to improve the fatigue strength of the workpiece. After shot peening, the dirt on the workpiece surface is removed, the workpiece surface is not damaged, and the surface area is increased. Since the workpiece surface is not damaged during the processing, the excess energy generated during the processing will cause the surface of the workpiece matrix to be strengthened. The high-speed rotating impeller is used to throw small steel or iron shots to hit the surface of the part at high speed, so the oxide layer on the surface of the part can be removed.

Sandblasting

Sandblasting is a process of cleaning and roughening the surface of a substrate by the impact of high-speed sand flow, that is, using compressed air as a power to form a high-speed jet beam to spray the material (copper ore sand, quartz sand, corundum, iron sand, Hainan sand) at high speed onto the surface of the workpiece to be processed, so that the appearance or shape of the outer surface of the workpiece surface changes. 1. Pack the sealing surface and knife edge of the chamber to prevent sand from being sprayed; 2. Sandblast the chamber according to user requirements (120 molybdenum sand and 80 molybdenum bowl are neutralized in a ratio of 2:1) 3. After sandblasting, rinse the chamber with clean water, blow dry with an air gun, then wipe it with alcohol, and let it dry naturally for half a day.

Mechanical polishing

Mechanical polishing is a polishing method that relies on cutting and plastic deformation of the material surface to remove the convex parts after polishing to obtain a smooth surface. Generally, petroleum strips, wool wheels, sandpaper, etc. are used, and manual operation is the main method. Special parts such as rotating body surfaces can use auxiliary tools such as turntables. For high surface quality requirements, ultra-fine grinding and polishing methods can be used. Ultra-fine grinding and polishing uses special grinding tools, which are pressed tightly against the surface of the workpiece in a grinding and polishing liquid containing abrasives and rotated at high speed. Using this technology, the surface roughness can reach Ra0.008μm, which is the highest among various polishing methods. Optical lens molds often use this method.

Chemical polishing

Chemical polishing is to make the microscopic convex parts of the material surface dissolve preferentially in the chemical medium over the concave parts, so as to obtain a smooth surface. The main advantage of this method is that it does not require complex equipment, can polish workpieces with complex shapes, can polish many workpieces at the same time, and is highly efficient. The core issue of chemical polishing is the configuration of the polishing liquid. The surface roughness obtained by chemical polishing is generally several tens of μm.

Electropolishing

The basic principle of electropolishing is the same as that of chemical polishing, that is, it selectively dissolves the tiny protrusions on the surface of the material to make the surface smooth. Compared with chemical polishing, it can eliminate the influence of the cathode reaction and has a better effect. The electrochemical polishing process is divided into two steps: (1) Macro leveling: the dissolved product diffuses into the electrolyte, and the geometric roughness of the material surface decreases, Ra>1μm. (2) Micro leveling: anodic polarization, the surface brightness increases, Ra<1μm. (1) Greatly improve the surface corrosion resistance. Due to the selective dissolution of elements by electropolishing, a dense and solid chromium-rich solid transparent film is generated on the surface, and an isoelectric surface is formed, thereby eliminating and reducing micro-battery corrosion. (2) The microscopic surface after electropolishing is smoother and has a higher reflectivity than that after mechanical polishing. (3) Electropolishing is not limited by the size and shape of the workpiece. Electropolishing can be applied to workpieces that are not suitable for mechanical polishing, such as the inner wall of slender tubes, elbows, bolts, nuts and the inner and outer walls of containers.

Hawken mirror processing equipment: As a new polishing process, it has unique advantages in the processing of many types of metal parts. It can replace traditional grinding machines, rolling, boring, honing, polishing machines, belt machines and other metal surface finishing equipment and processes; making high-finish processing of metal workpieces a piece of cake. Hawken can not only polish, but also bring many additional benefits: it can improve the surface finish of the processed workpiece by more than 3 levels (the roughness Ra value can easily reach less than 0.2); and the surface microhardness of the workpiece is increased by more than 20%; and the surface wear resistance and corrosion resistance of the workpiece are greatly improved. Hawken can be used to process various stainless steels and other metal workpieces.

Ultrasonic polishing: The workpiece is placed in an abrasive suspension and placed in an ultrasonic field together. The abrasive is ground and polished on the workpiece surface by the oscillation of the ultrasonic wave. Ultrasonic processing has a small macroscopic force and will not cause deformation of the workpiece, but it is difficult to make and install the tooling. Ultrasonic processing can be combined with chemical or electrochemical methods. On the basis of solution corrosion and electrolysis, ultrasonic vibration is applied to stir the solution to separate the dissolved products on the surface of the workpiece, and the corrosion or electrolyte near the surface is uniform; the cavitation effect of ultrasonic waves in the liquid can also inhibit the corrosion process and facilitate surface brightening.

Fluid polishing: Fluid polishing relies on high-speed flowing liquid and the abrasive particles it carries to flush the surface of the workpiece to achieve the purpose of polishing. Common methods include: abrasive jet processing, liquid jet processing, fluid dynamic grinding, etc. Fluid dynamic grinding is driven by hydraulic pressure to make the liquid medium carrying abrasive particles flow back and forth at high speed over the surface of the workpiece. The medium is mainly made of special compounds (polymer-like substances) with good flowability at low pressure and mixed with abrasives. The abrasive can be made of silicon carbide powder.

Magnetic grinding and polishing: Magnetic grinding and polishing uses magnetic abrasives to form abrasive brushes under the action of a magnetic field to grind the workpiece. This method has high processing efficiency, good quality, easy to control processing conditions, and good working conditions. With the use of suitable abrasives, the surface roughness can reach Ra0.1μm. The polishing mentioned in plastic mold processing is very different from the surface polishing required in other industries. Strictly speaking, the polishing of molds should be called mirror processing. It not only has high requirements for polishing itself, but also has high standards for surface flatness, smoothness and geometric accuracy. Surface polishing generally only requires a bright surface. The standards for mirror processing are divided into four levels: AO=Ra0.008μm, A1=Ra0.016μm, A3=Ra0.032μm, A4=Ra0.063μm. Since it is difficult to accurately control the geometric accuracy of parts by methods such as electrolytic polishing and fluid polishing, and the surface quality of chemical polishing, ultrasonic polishing, and magnetic grinding polishing does not meet the requirements, the mirror processing of precision molds is still mainly mechanical polishing.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)