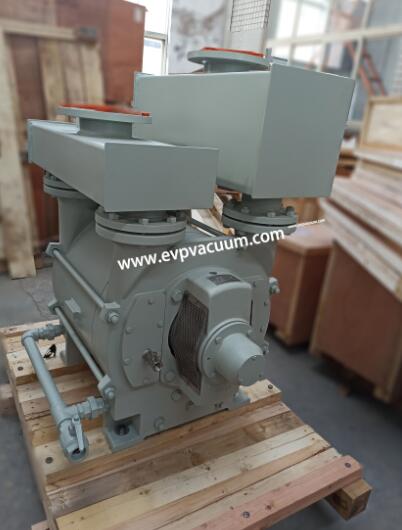

Vacuum pump for water tank vacuum drinking

In this application, the vacuum pump is used to maintain the siphon in the cooling water system of the power plant. The maintenance siphon enables the cooling water circulating pump to maintain the designed cooling water flow with less power consumption. Single stage liquid ring pump packages, usually equipped with specially designed starting valves, are ideal for this application, as they prevent water masses from being sucked into the pump. Learn more about applications.

Next, we will introduce the knowledge of vacuum pump used for water tank vacuum drinking water. If you want to know more about vacuum pump, please click to connect us.

Mechanical vacuum pump cleaning of six key points

Vacuum pump is a kind of device to produce, improve and maintain vacuum in a closed space by various methods. Vacuum pump can be defined as a device or equipment that uses mechanical, physical, chemical or physicochemical methods to extract air from the container to obtain vacuum. The use of mechanical movement (rotation or sliding) to obtain vacuum pump, known as mechanical vacuum pump. Mechanical vacuum pump cleaning should pay attention to what matters? Today and small make up together to understand it!

Matters needing attention when removing and washing mechanical vacuum pump

1. Disassembly and cleaning of mechanical vacuum pump should be carried out in the clean room. During disassembly and cleaning, attention should be paid to the original location, square and combination tightness of each component, and records should be made to avoid wrong installation;

2. When taking out the rotating blade and rotor, it is necessary to hold the rotating blade tightly by hand. The reason is that the rotating blade is subject to large spring force, and it is easy to fly out of hand if you are not careful, which will damage the edge or surface of the rotating blade and can not be used any more.

3. The removed parts should be separated and properly handled to avoid mutual collision or loss.

4. During assembly, a small amount of vacuum pump oil should be coated on the surface of rotating parts for lubrication. Pay attention to cleaning. It is strictly prohibited that iron chips, mud, sand and dust fall into the vacuum pump. The installed vacuum pump should rotate easily without uneven weight and blocking.

5. After the final assembly, add vacuum pump oil from the oil filling hole to the oil mark.

6. Before start-up, a small amount of vacuum pump oil should be injected into the suction port to make the vacuum pump fully lubricated. (the reassembled vacuum pump should be tested for several hours to see if it meets the requirements.)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)