vacuum system basic requirements

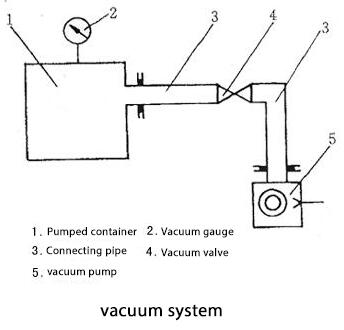

Vacuum system refers to a device which can meet certain vacuum requirements by connecting vacuum pumps, vacuum gauges and various parts through pipes in an appropriate way. What are the basic requirements of the vacuum system?

1, get the required limit vacuum and working vacuum in the device or studio. Limit vacuum degree is the vacuum degree that the device achieves without leakage and discharge. Working vacuum degree is the vacuum degree that can be maintained when the device is vacuum treated. A large amount of gas is emitted during vacuum treatment, and the working vacuum will be significantly lower than the limit vacuum. Limit vacuum degree and working vacuum degree have their respective importance. They affect the quality of devices from different aspects. For example, in the exhaust vacuum system using oxide cathode devices, the degassing of electrodes 10-2 and cathode decomposition will produce a large amount of gas. If the working vacuum is poor, the result of poorly oxidized electrodes and cathode activation may occur. However, there is almost no leakage when the device is finally sealed off. The vacuum degree in the device depends on the limit vacuum degree of the exhaust vacuum system.

2, the time needed to obtain a working vacuum. This time depends on the pumping speed of the vacuum system. Increasing pumping speed can shorten this time. Big studios obviously need a big pumping speed. Sometimes the studio is small, but because of the serious leakage, the vacuum system also needs a large pumping speed, otherwise a large amount of leakage will greatly reduce the vacuum, making the system unable to work.

3, there are suitable residual components in the device or studio. Practice has proved that it is not enough to simply improve and ensure the limit vacuum and working vacuum, and there should be certain requirements for residual gas composition. For example, in order to maintain the sensitivity reduction within one year life of vacuum camera devices, the oxygen content of residual gases in the devices should not be higher than 10-2 Pa high-voltage vacuum switch tube, and hydrocarbon molecules should not be included. The residual components of the vacuum system, such as no other gas source in the system, are mainly determined by the characteristics of the pump.

4. In addition, the vacuum system must be simple in structure, reliable in performance, convenient in operation and maintenance, and inexpensive in price. To meet these requirements, comprehensive consideration must be given to the selection of pumps, the determination and layout of pipe sizes, and the assembly process. These basic requirements are often interrelated. For example, because the vacuum system always has the phenomenon of micro leakage, the pump with high pumping speed can obtain better working vacuum than the pump with low pumping speed, but the large pump is expensive, consumes more water and electricity, so there is a problem of reasonable selection. Miniature vacuum pumps are suitable for instruments and small vacuum systems. They are low cost, high efficiency and low noise. It is not appropriate for some users to choose industrial vacuum pumps with large flow rate.

5. Automation requirements. With the development of computer technology, the automation requirements of users for vacuum systems are also rising. For vacuum system, automatic control is mainly for the regulation of vacuum pump flow and vacuum. Vacuum is often controlled by regulating the flow of vacuum pump, installing throttle valve and pressure relief valve. The use of throttling is a good way to directly adjust the speed of vacuum pump. There are many kinds of speed regulation methods for industrial vacuum pumps, which are mainly divided into two categories: the first is that the speed of the motor is unchanged, and the speed of the vacuum pump is changed by additional devices, such as gearbox speed regulation; the second is that the speed of the motor is changed directly, such as thyristor cascade speed regulation, frequency conversion speed regulation and so on. At present, the commonly used method of industrial vacuum pump is frequency conversion speed regulation, which has good energy-saving effect. It can realize stepless speed regulation with large speed ratio, precise speed regulation and stable speed. For miniature vacuum pumps suitable for small vacuum systems, in the past, the main use of step-down speed regulation, step-down operation has the added advantage of prolonging the life of pumps and motors. If the load of the pump is large, it is easy to cause the motor to be unable to start after reducing the voltage, so that the temperature of the motor rises, resulting in potential safety hazards. At present, the most advanced domestic “air-sea” speed-regulating micro-vacuum pump is equipped with imported DC motor, with PWM (Pulse Width Modulation) line, which can easily and reliably regulate flow, output motor speed feedback signal (FG), real-time monitoring of motor working conditions, and more convenient for automatic control. It also has a perfect self-protection function. It can automatically stop when the pump dies are dead and overheated. The speed governing miniature vacuum pump is an ideal choice for automation of small vacuum systems. Generally speaking, for a vacuum system with better air tightness, if there is no regular exhaust and no steam source inside, a smaller pump with better limit vacuum can be used. However, if the system leaks more air, it must use the method of increasing pumping speed to ensure its working vacuum. At this time, a pump with larger pumping speed should be adopted, and the pipeline conductivity should be increased as much as possible, that is, the short and thick pipeline should be selected.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)