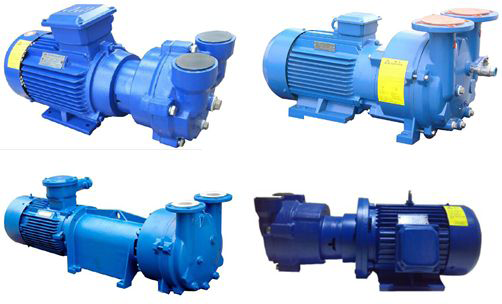

Water ring vacuum pump impeller assembly

The vacuum pump is made up of: pump cover, pump body, disk, impeller, mechanical seal, motor and other parts. Properly assembling the impeller on the shaft can ensure that the water ring vacuum pump has good volume efficiency and prevent vibration.

Vacuum pump impeller center hole there is a screw hole on each side, to be a tool, a middle thick plate drilling, tapping, the size is smaller than the motor shaft, the hole at each end milling a slot, bolt fix the two screw holes on the impeller impeller, with a larger spin top tight motor shaft bolt and rotate this bolt with the motor shaft, impeller will slowly come out. If it’s too tight to get out, you can use a fire – baked impeller to inflate it out of the impeller.

When the impeller is mounted on the shaft, its end face must beat within the allowable range. Cover before and after impeller with axial clearance is small, big face runout will cause the impeller and the front and back cover of eccentric wear, not only to pump heat, increase power consumption, but also will increase the end clearance, increase the compression zone gas through the side clearance leakage, reduce the volumetric efficiency.

In addition to the shape error of the end face, the size of the end face depends mainly on whether the impeller is properly mounted on the shaft. For this reason, apply even force when assembling, do not touch shaft hole and shaft. After the impeller is mounted on the shaft, the imbalance of the impeller should be checked in addition to the requirement of end face pulsation.

Although the impeller when the design is the requirement of symmetrical distribution, but due to the defect in the castings such as blow hole, shrinkage cavity in the other casting, the quality of machining parts distribution is not uniform, make its center of gravity and center of rotation is not coincidence, so that in the rotating impeller centrifugal force generated when additional or couple, cause the vibration. This kind of vibration is very harmful, it makes the parts inside the pump loose, but also makes the force acting on the bearing uneven, resulting in the bearing eccentric wear, premature damage. In addition, if the vibration frequency is equal to the natural vibration frequency of the pump or foundation, resonance will occur, and the water ring vacuum pump unit or foundation will be damaged when resonance occurs. Therefore, measuring and eliminating the unbalanced force of impeller is one of the most important steps in the assembly and repair of water ring vacuum pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)