Water Ring Vacuum Pump in Thermal Power Plant

Absrtact: The working principle, technical performance and structural characteristics of water-ring vacuum pump are introduced. The water-ring vacuum pump is compared with other pumping equipment, and its optimal operation is discussed.

Working Principle and Composition of Pump Set System

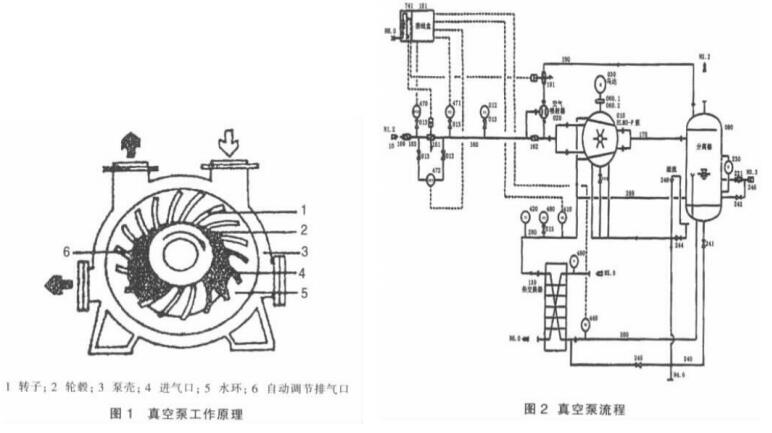

1.1 Water Ring Vacuum Pump working principle

Water ring vacuum pump is a kind of volume pump. As shown in Fig. 1, the impeller and the pump shell are not the same axis, but have a certain eccentricity. When the rotor rotates, the volume of the rotating part will gradually increase and the air will be exhausted if the volume of the rotating part is gradually reduced. Specifically, eccentricity is installed in the pump body filled with appropriate working water. When the rotor with several forward-bending blades rotates in the pump body, it will form a pump and pump, thus realizing the purpose of vacuum suction. Among them, working water plays the following roles: 1) like a piston; 2) cooling the exhausted gas;

3) condensing the exhausted steam.

1.2 Water Ring Vacuum Pump system composition

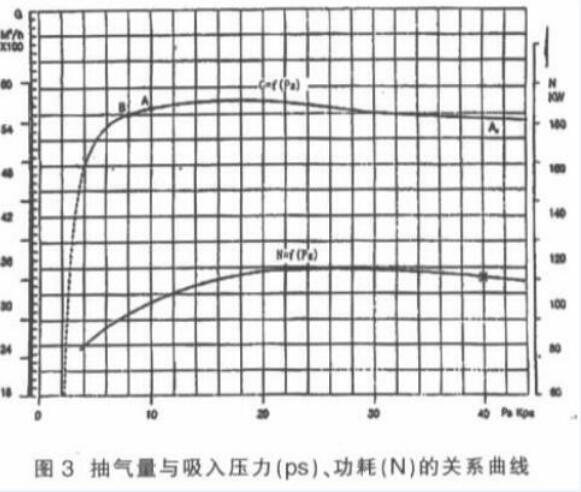

The 2BW1-353-0 water-ring vacuum pump group consists of 2BW1-353-0 water-ring vacuum pump, low-speed motor, gas-water separator, pre-pump, working water cooler, water level device and related pipes, valves and control equipment. The working flow of the pump group is shown in Figure 2. The gas extracted from the condenser enters the vacuum pump (010) through the suction port (N1.2), the check valve (163), the pneumatic butterfly valve (161, 162) and the pipeline (160). The gas discharged from the vacuum pump enters the gas-water separator (080) through the pipeline (170), and the separated gas enters the gas outlet (N2.2). Into the atmosphere. Separated water and working water through water level regulator (221)

The water ring, the blade and the end caps on both sides of the pump are enclosed in a number of small spaces. Each small space of the rotor changes periodically from small to large and from large to small in every rotation cycle. When the process of

space change is small to large, the space will produce vacuum and inhale gas through the intake port. When the space changes from large to small, pressure will be generated in the space, and the gas will be compressed and discharged through the exhaust port. When the rotor rotates continuously, the pump will continuously suck and exhaust.

The supplementary water enters the cooler (130) for cooling and then enters the vacuum pump.

When the atmospheric ejector is running, the pressure switch (741) is turned on, the butterfly valve (191) is opened and the butterfly valve (162) is closed, and the atmospheric ejector is put into operation.

2.water ring vacuum pump structural characteristics:

In order to improve the volumetric efficiency and isothermal compression efficiency of the vacuum pump in the whole range of suction pressure, 2BE1 series water ring vacuum pumps adopt automatic regulating gas outlet and reasonable shape exhaust distributor. Because there is a flexible PTFE plate covering the exhaust distribution plate, when the gas pressure in the compressor chamber of the impeller is less than the pressure at the gas outlet, the PTFE plate is covered by the pressure difference at the exhaust outlet of the distribution plate. When the impeller continues to rotate to the compressor chamber of the impeller, when the gas pressure equals to the outside, the PTFE plate is opened and the gas is discharged. In this way, the sucked gas must be discharged at a constant pressure, avoiding the power loss caused by the over-compression of the gas. In addition, the pump also adopts bilateral axial suction and exhaust structure. The impeller is assembled with the hot sleeve of the spindle. The impeller shape is that the middle part of the hub is higher than the two ends, which strengthens the mechanical strength of the blade. In order to prevent wear and tear of disk roots and axles, chromium steel protective sleeve is used. Shaft packaging device can adopt either internal water supply mode or external water supply mode.

The 2BW4-353 vacuum pump group adopts the internal water supply mode, that is, the shaft seal water is directly taken from the vacuum pump water ring, without any external piping and equipment. As for the vulnerable parts of vacuum pump, Siemens considers that it is not necessary to replace the vulnerable parts frequently, only the filler of shaft seal needs to be replaced once a year because of wear and tear. In addition, the main components of 2BW4-353-0 vacuum pump, such as impeller, pump body, front and rear distributor plates, front and rear side covers, are made of nickelchromium alloy, which makes the vacuum pump corrosion resistant.

3.1 Hogging

When the unit starts, the condenser, low pressure cylinder and other vacuum systems are at the speed of 590 rpm and power of 135 KW.

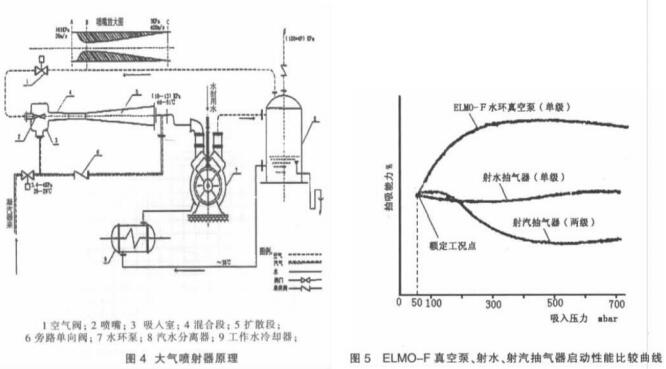

The relationship between compressed gas volume (G) and inhalation pressure (Ps), i.e.

G = f (Ps), and between axis power (N) and inhalation pressure (Ps), i.e. N = f (Ps), is

shown in Fig. 3.

(2) Analysis of the Stable Section of Performance Curve (Low Vacuum Section)

The operation is stable, so this section can make the water ring vacuum pump in the optimal operation state.

In atmospheric condition, after being put into the steam seal, only the air part is pumped through the vacuum equipment.

In addition, it should also be seen from the performance curve that it has a larger suction capacity, that is, all of it is pumped out in a relatively short time to form partial or complete vacuum.

G = 5400m3/h, therefore, it can guarantee the water ring under any harsh conditions.

Therefore, the pumping equipment is required to have a larger volume flow, which is called rapid real-time pumping.

Stability, to adapt to large compression ratio, to ensure the normal operation of water ring vacuum pump.

Air Equipment – Rapid Evacuation Equipment – HEI Standard, to a factory

(3) Performance Analysis of High Vacuum Section

Taking 350MW unit as an example, according to this standard, the requirements for this type of unit are as follows:

Another section of the G = f (Ps) performance curve in Figure 3 is that the vacuum system of A-B-C-C0 condenser quickly reaches a corresponding value (30 minutes) from the atmospheric state.

The section is a high vacuum section. When the water ring vacuum pump runs in this section, it behaves well.

Vacuum value (-67 kPa or more) required for start-up, capacity of vacuum pumping equipment The instability of the output performance, even if the inhalation pressure changes slightly, will cause The pumping capacity of 2BW4-353-0 vacuum pump is far from 2000 m3/h.

The amount of inhaled gas changed greatly. When the unit enters normal operation condition

It is larger than this value (5000m3/h) and only needs to run in the stable section of the performance curve.

If the vacuum is relatively high, the vacuum pump will run in this section. At this time, the water ring vacuum Therefore, 2BW4-353-0 vacuum pump is a good start-up pumping.

The medium sucked by the pump from the operating unit is no longer ideal gas (air), but the pump can fully meet the start-up conditions of the unit. At the same time, a steam turbine unit

It is a mixture of steam and gas, in which steam is cooled and compressed into water, and the release is equipped with two vacuum pumps with 100% capacity. When starting, two are true.

Because of the large heat output, this section is also the cavitation section of the water ring pump. The long-empty pump runs together, which shortens the start-up time.

In this operation, the impeller of the water ring vacuum pump will be damaged, which will affect the life of the pump, and thus will decrease.

3.2 Holding

Reliability and safety of low pump operation. Because the single-stage water ring vacuum pump should be operated by a vacuum pump and a standby one under normal operating conditions.

It bears a large compression ratio, so its limit vacuum will be lower, so when the pump set starts, only when the pressure difference between front and back of the imported butterfly valve (161) is less than 3kPa.

From the G = f (Ps) performance curve in Figure 3, it can be seen that the performance curve is basically divided into two sections, the A0-A section of which is called stable (or working section). The basic performance of this section is that it can gradually increase the vacuum of the condenser and its system with a relatively stable suction capacity, that is, the relationship between G=f(Ps) changes smoothly and the water ring pump changes smoothly.

When the value can be adjusted, the imported butterfly valve (161) opens and the gas in the condenser vacuum system is pumped into the vacuum pump through the imported butterfly valve (161). In this way, a large amount of air can not be poured back into the condenser vacuum system by starting the vacuum pump

4 Technical Performance Analysis and Optimized Operation

(1) technical specifications

At this point, the Ejector will be put into operation.

(4) Effect of actual working water temperature on suction capacity of vacuum pump

When the actual working water temperature rises, the actual suction capacity of the vacuum pump decreases.

On the contrary, when the working water temperature decreases, the suction capacity of the vacuum pump increases. Therefore, the normal operation of the working water cooler should be guaranteed so that the suction capacity of the vacuum pump can be maintained at a normal level.

(5) Principle and Application of Atmospheric Ejector

In order to overcome the performance defect of single-stage water ring vacuum pump, an air ejector and a single-stage vacuum pump together constitute a set of vacuum pumping equipment with better technical performance. Its principle is shown in Fig. 4. Because the working medium of the Ejector is the exhaust of air or water ring vacuum pump under atmospheric pressure, it does not consume power while

working, but it can improve the working condition of single stage water!! Thisimprovement is reflected in the following aspects:

(1) The compression ratio of water-ring vacuum pump nearly 30 is reduced to about 10, which greatly improves the working conditions of the impeller of water-ring vacuum pump.

(2) It can extend the limit vacuum that raw water ring vacuum pump can not reach, and expand the performance and scope of vacuum equipment, especially high vacuum section.

(3) The channel of the air ejector is cylindrical, and the rule of the channel changes smoothly. Therefore, it can replace the water ring vacuum pump to run in the high vacuum section in order to prevent cavitation and improve the safety, reliability and operation life of the equipment.

(4) After the Ejector is put into operation, the technical performance requirements of the working water cooler of the water ring vacuum pump can be weakened.

In summary, the air ejector in series in front of the water ring pump is actually a good operating air extractor, but its design parameters can only be determined according to the operating conditions. According to the specific performance curve of the water ring vacuum pump, the entry point of the air ejector in operation (i.e. the value of point B in the curve) is definitely not allowed to be designed as starting pumping. The overlapping relationship between the discharge parameters and the suction

parameters of the water ring pump should also be paid attention to, and the reasonable range of the working conditions should be neglected, so that the ejector can not operate well under overload.

(6) The good operation of vacuum pumping equipment is closely related to the circulating water of condenser. When the condition of condenser deteriorates due to the deterioration of circulating water and temperature, the vapor partial pressure ratio in the extracted vapor-gas mixture will increase, and the vapor volume in the mixture will increase, which will affect the working condition of the pumping equipment. In serious cases, the water-ring vacuum pump will become a rotating heat exchanger.

Therefore, while discussing how to optimize the operation mode of vacuum pumping equipment, this is a problem that has to be considered.Performance comparison of water ring mechanical vacuum pump with water jet and steam ejector

5.1 Startup Performance Comparison

It is well known that a certain vacuum must be set up in the condenser before the condensing steam turbine runs, and the vacuum of the condenser must depend on the suction or short. As shown in Fig. 5, when the water ring vacuum pump, water ejector and steam ejector are under 5 KPa suction pressure, they all have 100% suction capacity. The suction capacity of ELMO-F vacuum pump under low vacuum is far greater than that of water jet and steam jet under the same suction pressure.

Therefore, when the water ring vacuum pump is started, the time needed to establish the vacuum is much shorter than that needed to establish the same vacuum by using water jet or steam ejector.

5.2 Comparison of Normal Operation Performance

German experts have made some economic comparisons. Under the same parameters, under normal operation, ELMO-F vacuum pump only needs 0.126 marks per kilogram (air) hour, while water jet pump needs 0.196 marks per kilogram (air)

hour. Compared with steam ejector, ELMO-F vacuum pump only needs 0.079 mark per kilogram (air) hour, while water ejector needs 0.079 mark per kilogram (air) hour.

0.31 Mark.

6 concluding remarks

From the above analysis, we can see that the water ring vacuum pump has the following characteristics:

Control is simple.

(2) Low power consumption. (3) Low operating costs.

(4) When the inlet pressure rises, the pumping capacity will rise rapidly (water jet and steam jet will reduce the pumping capacity with the increase of the inlet pressure).

This characteristic is conducive to start pumping, and when the leakage of the vacuum system increases in operation, only a small vacuum reduction will occur.

The rotational speed of water ring vacuum pump is low, and its noise and vibration will be reduced.

There is no metal friction surface in the pump.

The structure is simple and easy to manufacture, so it works reliably and is not easy to break down. It is easy to maintain.

It can be seen that the water ring vacuum pump has good performance and is a good vacuum pumping equipment in thermal power plants. At present, it has been widely used in large units instead of water jet pumps.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)