water ring vacuum pump in vacuum belt filter of application

The so-called filtration is to generate a pressure difference on both sides of a porous filter medium such as a filter cloth, and the solid particles in the filter slurry are trapped by the filter medium, thereby separating the liquid and solid phases. The vacuum filtration uses the pressure difference between the vacuum source on the side of the filter medium and the atmospheric pressure on the side of the filter slurry (usually 4.9×104Pa-6.68×104Pa) for filtration.

The mechanism of vacuum filtration is mostly filter cake filtration, and some are deep filtration. The vacuum filter and other accessory devices are used to achieve vacuum filtration. Whether it is a belt filter, a disc filter, a drum filter, a ceramic filter or other forms of filter, as an important part of the accessory device, the water ring vacuum pump is the first choice to provide the vacuum source.

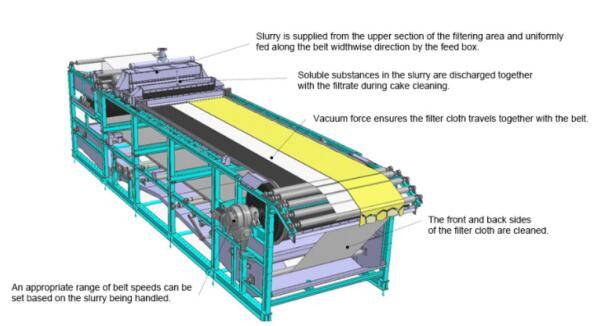

Belt vacuum filter is a kind of high-efficiency filtration solid-liquid separation equipment independently developed on the basis of introducing foreign technology of similar products. The equipment uses a fixed vacuum box, the tape slides on the vacuum box, the vacuum box and the tape form a movable seal structure, and the vacuum negative pressure is used as the driving force to realize the solid-liquid separation equipment.

In terms of structure, the filter section is arranged along the horizontal length direction, which can continuously and automatically complete the process operations such as filtration, filter cake washing, slag unloading, filter cloth regeneration, and the mother liquor and filter cake washing liquid can be collected in sections. It has the advantages of high filtration efficiency, large production capacity, good washing efficiency, low water content of the filter cake, flexible operation and simple maintenance. The belt conveyor has been improved and perfected by the factory for many years, and the technical performance and quality of the product have reached the international advanced level. It has been widely used in solid-liquid separation in the fields of metallurgy, mining, chemical industry, papermaking, food, pharmaceuticals, coal washing, and environmental protection. Especially in the aspect of gypsum dehydration (FGD) in flue gas desulfurization, it has a good application. The main configuration of the belt vacuum filter is as follows:

Shanghai EVP Vacuum Technology Co., Ltd. has provided satisfactory vacuum solutions for many belt vacuum filter customers. The following is an illustration for reference.

The customer requirements are:

“We need a vacuum pump with an operating pressure of 6500 m3/h -0,4 bar,

With boric acid,

The temperature entering the vacuum pump is 50-65℃

Water temperature on site 20C

The slurry is boric acid, so the flow parts of the vacuum pump must be SS316Ti”

After communicating with the customer in various aspects, we decided to choose the EVP brand 2BE3-40. The following are customer’s on-site usage pictures:

We 6500 m3/h -0,4 bar Operating pressure Vaccum Pumps,

Process is Boric Acid,

Temp entering to vacuum pump is 50-65 C

Liquid ring water temp 20C

Slurry is Boric Acid so We have to use for touch places to slurry is SS316Ti

Edited by: Shanghai EVP Vacuum Technology Co., ltd

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)