vacuum pump in vacuum smeltingn of application

Vacuum pumps play a key role in metal smelting. They are mainly used to create and control low pressure or vacuum environment, which is essential for improving metal purity, preventing oxidation, removing harmful gases and melting special alloys. The following are its specific applications and English translations:

1.Vacuum Degassing

– Application: Before pouring molten steel, vacuum treatment is used to remove dissolved gases such as hydrogen, oxygen, and nitrogen to prevent pores, white spots or embrittlement in steel.

– Process types:

– VD (Vacuum Degassing): Ladle vacuum degassing.

– RH (Ruhrstahl-Heraeus): Circulating vacuum degassing (molten steel is degassed in a vacuum chamber).

– VOD (Vacuum Oxygen Decarburization): Vacuum oxygen decarburization (used for stainless steel smelting).

– Vacuum requirements: 0.1–1 mbar (10⁻²–10⁻³ Pa).

Liquid ring vacuum pump

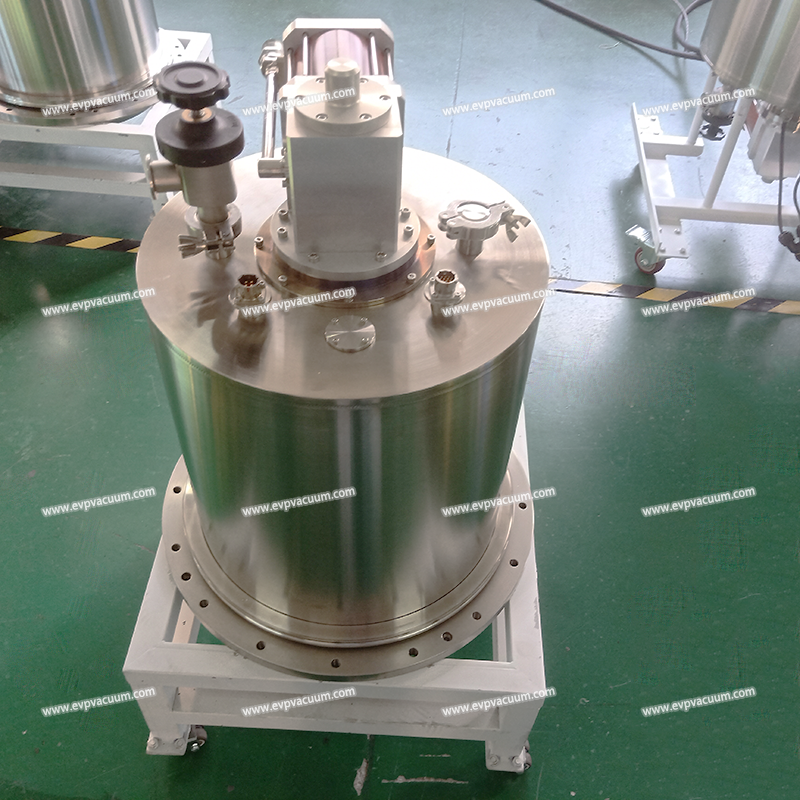

2.Vacuum Induction Melting (VIM)

– Application: Melting high-temperature alloys (such as nickel-based alloys), titanium alloys, etc. in a vacuum environment to avoid oxidation and accurately control the composition.

– Key advantages:

– Prevent oxidation of active metals (such as Ti, Al);

– Remove impurities such as S and P;

– Accurately add trace elements (such as B, Zr).

– Vacuum requirements: 10-3–10-6mbar (10-1–10-4Pa).

Double stage rotary vane pump

Roots pump

3.Vacuum Arc Remelting (VAR)

– Application: Secondary refining of melted alloys (such as high-temperature alloys, titanium alloys) to eliminate inclusions and improve the crystal structure.

– Process: Direct current is passed through the vacuum chamber to cause the consumable electrode to arc melt and resolidify.

– Vacuum requirement: 0.01–0.001 mbar (10-3–10-4Pa).

Dry screw vacuum pump

4.Electron Beam Melting (EBM)

– Application: Use high-energy electron beam to melt high-melting-point metals (such as tantalum, niobium, tungsten) or active metals (titanium alloys) under vacuum to achieve deep degassing and impurity volatilization.

– Vacuum requirement: 10-4–10-6 mbar (10-2–10-4Pa).

Cryogenic pump

5.Vacuum Sintering

– Application: In powder metallurgy, cemented carbide (such as WC-Co), magnetic materials, etc. are sintered in a vacuum environment to avoid oxidation and promote densification.

– Vacuum requirement: 10⁻²–10⁻⁴ mbar (1–10⁻² Pa).

Molecular pump

6.Zone Melting

– Application: Zone purification of semiconductor materials (such as silicon, germanium) or high-purity metals under vacuum, using the segregation effect to remove impurities.

– Vacuum requirement: 10-5–10-7mbar (10-3–10-5Pa).

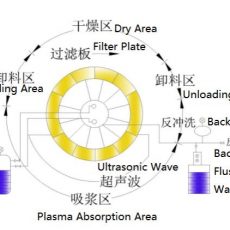

7.Vacuum Casting

– Application: Casting titanium alloys, high-temperature alloys, etc. in a vacuum environment to reduce pores and inclusions in castings.

– Process type: Vacuum Suction Casting.

Roots -screw vacuum package

Liquid ring-roots vacuum package

Vacuum Pump Types and Selection

| Process* | Common Vacuum Pump Types | Operating Pressure Range

| VD/VOD | Steam Ejectors | 0.1–10 mbar |

| VIM/VAR | Roots + Diffusion Pumps | 10⁻³–10⁻⁶ mbar |

| EBM | Turbomolecular Pumps | 10⁻⁴–10⁻⁸ mbar |

| Vacuum Sintering | Dry Screw Pumps | 10⁻²–10⁻⁴ mbar |

Core Value Summary

– Degassing and impurity removal: eliminate H₂/O₂/N₂ and improve metal toughness;

– Anti-oxidation: protect active elements (Ti, Al, Zr);

– Control composition: accurately add volatile alloying elements;

– Improve structure: reduce inclusions and optimize crystal structure.

These applications have significantly improved the performance of high-end metal materials in aerospace, medical equipment, nuclear industry and other fields.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)