Water Ring Vacuum Pump in Vacuum Filtration Process of Application

Filtration is to generate a pressure difference on both sides of a porous filter medium such as a filter cloth, and the solid particles in the filter slurry are trapped by the filter medium, thereby separating the liquid and solid phases.

The vacuum filtration uses the pressure difference between the vacuum source on the side of the filter medium and the atmospheric pressure on the side of the filter slurry (usually 4.9×104Pa-6.68×104Pa) for filtration. Vacuum filters are widely used in metallurgy, geology and mining, coal, chemical, building materials, light industry, agriculture and other related industries. They are also widely used in laboratories, laboratories or pilot plants in universities, colleges and scientific research institutes for continuous or intermittent Filter work.

The mechanism of vacuum filtration is mostly filter cake filtration, and some are deep filtration. The vacuum filter and other accessory devices are used to achieve vacuum filtration. Whether it is a belt filter, a disc filter, a drum filter, a ceramic filter or other forms of filter, as an important part of the accessory device, the water ring vacuum pump is the first choice to provide the vacuum source.

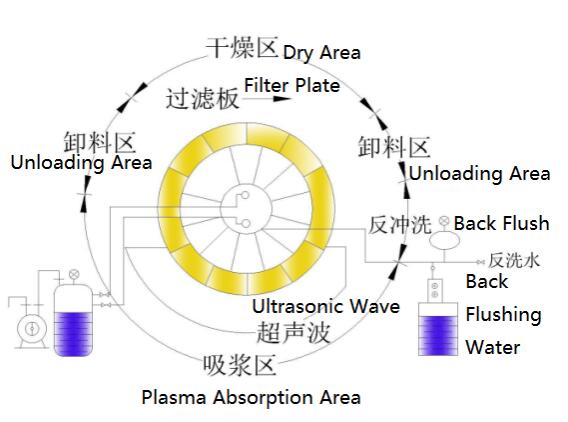

For example, the working principle of ceramic filter:

Ceramic filter is a high-tech solid-liquid separation product developed by ourselves based on the principle of capillary action and combined with the development of ceramic technology. It has the advantages of high filtration efficiency, low production cost, energy saving and consumption reduction, clean and environmental protection. Its structure is mainly composed of roller system, mixing system, feeding and discharging system, vacuum system, filtrate discharge system, scraping system, hair washing system, combined cleaning (ultrasonic cleaning, automatic acid cleaning) system, automatic control system, tank The body and the frame are composed of several parts. It has been widely used in mine non-ferrous metals, rare metals, ferrous metals, non-metals and other concentrates and tailings dehydration, chemical industry oxides, electrolytic slag, leaching slag, slag dehydration and environmental sewage sludge waste acid treatment. The fineness of materials ranges from -200 to -450 mesh and various ultra-fine materials.

Schematic diagram of working principle

The composition of the vacuum system: consists of a vacuum pump, a drain tank and related pipelines. The vacuum pump operates to form a vacuum in the drain tank. One end of the relevant pipeline is connected to the drain tank, and the other end is communicated with the ceramic filter plate through the distribution head to absorb solids on the surface of the filter plate, and the filtrate is sucked into the drain tank.

Different series of filter equipment, as well as the complex working conditions, have different requirements for the vacuum degree, pumping capacity and other technical parameters of the vacuum pump. In view of the different process requirements of vacuum filtration production, Shanghai EVP Vacuum Technology Co., Ltd. has the following advantages in design and manufacturing:

1. High efficiency, low maintenance, and lower operating costs.

2. A number of patented technologies, advanced product design, and provide the highest quality design solutions.

3. Simple and effective instrument control, easy to operate, maintain and monitor.

4. Advanced processing equipment and testing methods, strict quality management system to ensure product reliability and stability.

5. The perfect after-sales service network provides you with fast and efficient service.

Water ring vacuum pumps widely used in filtration process

2BV series products:

The suction pressure can reach 33mbar absolute pressure

Pump coaxial direct connection design, saving space and easy to install

Precision casting and CNC machine tool precision processing to ensure the accuracy of the product

The mechanical seal is used as the standard configuration, which eliminates leakage and is easy to maintain

Smooth operation, noise can be as low as 75 decibels

2BE series products

Firm thermal fit interference fit between shaft and impeller hole

Large shaft and bearing safety factor

Welded impellers, hubs and blades are all processed, and the whole is heat-treated, with balanced operation, impact resistance and low noise.

System optimization, reasonable structure, high efficiency

Flexible exhaust valve design to avoid over-compression of gas and reduce energy consumption

Can meet the most complex industrial requirements

DLV series products

Reliable design and simple operation

Easy to install and easy to maintain

Wide range of applications

Under higher vacuum, with larger pumping capacity

Edited by: Shanghai EVP Vacuum Technology Co., ltd

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)