Water ring vacuum pump selection manual

2BE1 water ring vacuum pump selection manual

2BE1 water ring vacuum pump adopts single-stage and single-action structure form, which is an energy-saving product popularized by the country. It is usually used for pumping gases that do not contain solid particles and are insoluble or slightly soluble in working fluid. The vacuum pump generally USES water as the working fluid.

2BE1 water ring vacuum pump has the advantages of simple structure, reliable operation, high efficiency and energy saving, etc. It is the ideal product for vacuum dehydration, vacuum drying, vacuum filtration and pressure delivery in the electric power, petrochemical, coal, paper, tobacco, food, textile, metallurgy and pharmaceutical industries.

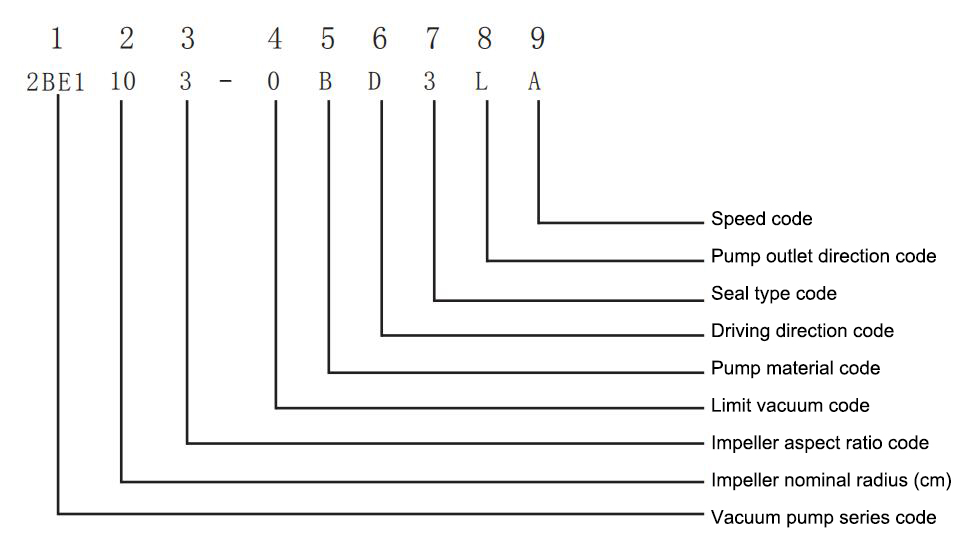

Model representation method

Water ring vacuum pump material distribution

The general standard configuration of 2BE1 series water ring vacuum pumps is as follows:

| Pump body | Carbon steel |

| Pump cover | Cast iron |

| The impeller | Ductile iron or carbon steel |

| Distribution board | Cast iron |

| Pump shaft material | Carbon steel |

| Mechanical seal | High wear resistant ceramic alloys and fluoroelastomers or corrosion and abrasion resistant fillers |

The following material configuration can also be selected according to the actual working conditions to improve the performance:

| Impeller, distribution plate, pump cover, pump body | SUS304(0Cr18Ni9)、SUS316(0Cr17Ni12Mo2)、SUS316L(00Cr17Ni14Mo2) |

| Pump shaft material | 2Cr13、SUS304 or SUS316L |

| Mechanical seal | High wear resistant ceramic alloys and fluoroelastomers or corrosion resistant fillers |

| Shaft sleeve | Cr28 high chromium stainless steel |

Water ring vacuum pump performance characteristics

Adopting the latest foreign advanced technology, it has large air volume and high efficiency (working efficiency of 2BE1 series vacuum pumps is up to 60%-70%, and efficiency of SK, 2SK and SZ series vacuum pumps is about 30-40%) and low noise.

Bearing all imported original bearings, to ensure accurate positioning of the impeller and high stability in the process of operation.

The impeller is made of ductile cast iron or welded with steel plate, which ensures the stability of the impeller under various bad working conditions and greatly improves the service life of the vacuum pump.

The vacuum pump body is made of high quality steel plate, which improves the service life.

As the most easily damaged parts, the company all made of high chromium stainless steel, than the ordinary material life increased 5 times.

Coupling (drive straight al) with a standard high strength elastic coupling, polyurethane (pu) material elastic element, stable and reliable operation, long service life.

Belt pulley (belt drive) adopts standard high-precision cone belt pulley, which runs reliably, has long belt life and is easy to disassemble.

The unique up-mounted gas-water separator not only saves space but also reduces noise.

The mechanical seal is made of high strength ceramic alloy to ensure no leakage during the long operation of the vacuum pump.

The wall profile of the vacuum pump body adopts the approximate ellipse profile to ensure the best vacuum pumping effect.

The over current parts can all be made of sus304/316 stainless steel, used for vacuums with acid and alkali corrosion or higher sanitary grade

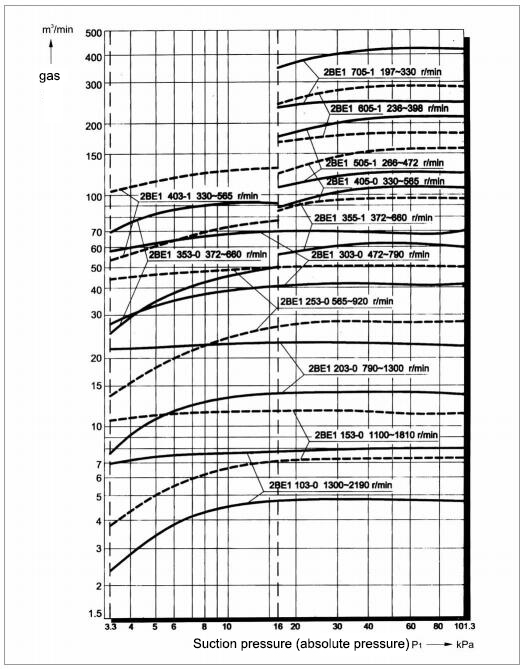

Water ring vacuum pump spectrogram (basic type)

Water ring vacuum pump performance table

| Model | Speed

(Driving mode) |

Shaft power | Motor power | Ultimate

vacuum |

Max. capacity | Weight (excl.

motor) |

|

| r/min | KW | 380V | hpa | M³/hr | M³/min | kg | |

| 2BE1-102 | 1450 (direct)

1750 (V-belt) |

6.0

8.0 |

Y132M-4-7.5

Y160M-4-11 |

33hpa

(-0.097MPa) |

246

290 |

4.1

4.8 |

110 |

| 2BE1-103 | 1450 (direct)

1750 (V-belt) |

8.2

11.1 |

Y160M-4-11

Y160L-4-15 |

33hpa

(-0.097MPa) |

340

412 |

5.7

6.9 |

125 |

| 2BE1-152 | 1450 (direct)

1625 (V-belt) 1750 (V-belt) |

12.5

15.0 17.2 |

Y160L-4-15

Y180M-4-18.5 Y180L-4-22 |

33hpa

(-0.097MPa) |

450

510 535 |

7.5

8.5 8.9 |

175 |

| 2BE1-153 | 1450 (direct)

1100 (V-belt) 1300 (V-belt) 1620 (V-belt) 1750 (V-belt) |

16.3

10.6 13.4 19.6 22.3 |

Y180M-4-18.5

Y160L-4-15 Y180M-4-18.5 Y180L-4-22 Y200L-4-30 |

33hpa

(-0.097MPa) |

600

445 535 648 700 |

10.0

7.4 8.9 10.8 11.7 |

200 |

| 2BE1-202 | 980 (direct)

790 (V-belt) 880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

18.2

13.4 16.3 23.8 25.7 30 |

Y200L2-6-22

Y180M-4-18.5 Y180M-4-18.5 Y200L-4-30 Y200L-4-30 Y225S-4-37 |

33hpa

(-0.097MPa) |

750

590 670 860 888 950 |

12.5

9.8 11.2 14.3 14.8 15.8 |

460 |

| 2BE1-203 | 980 (direct)

790 (V-belt) 880 (V-belt) 1100 (V-belt) 1170 (V-belt) 1300 (V-belt) |

29.5

21.2 24.8 34 38 42 |

Y250M-6-37

Y200L-4-30 Y200L-4-30 Y225M-4-45 Y225M-4-45 Y250M-4-55 |

33hpa

(-0.097MPa) |

1080

870 980 1210 1320 1390 |

18

14.5 16.3 20.2 22.0 23.2 |

530 |

| 2BE1-252 | 740 (direct)

565 (V-belt) 660 (V-belt) 830 (V-belt) 885 (V-belt) 938 (V-belt) |

38

23.7 31.8 45 54 60 |

Y280M-8-45

Y200L-4-30 Y225S-4-37 Y250M-4-55 Y280S-4-75 Y280S-4-75 |

33hpa

(-0.097MPa) |

1700

1200 1500 1770 2000 2100 |

28.3

20.0 25.0 29.5 33.3 35.0 |

870 |

| 2BE1-253 | 740 (direct)

565 (V-belt) 660 (V-belt) 740 (V-belt) 792 (V-belt) 820 (V-belt) 880 (V-belt) 940 (V-belt) |

54

37.2 45 50.8 60 68 75.1 88 |

Y315M-8-75

Y225M-4-45 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-75 Y280M-4-90 Y315S-4-110 |

33hpa

(-0.097MPa) |

2450

1690 2100 2340 2560 2640 2780 3050 |

40.8

28.2 35 39 42.7 44 46.3 50.8 |

930 |

| 2BE1-303 | 740 (direct)

590 (direct) 466 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

98

65.5 48 58 64 79.8 96 |

Y315L2-8-110

Y315L2-10-75 Y250M-4-55 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 |

33hpa

(-0.097MPa) |

4000

3200 2520 2820 3100 3550 3840 |

66.7

53.3 42 47 51.7 59.2 64 |

1700 |

| 2BE1-305 | 740 (direct)

590 (direct) 490 (V-belt) 530 (V-belt) 583 (V-belt) 660 (V-belt) 740 (V-belt) |

108

70 55 61 68 90 110 |

Y355M1-8-132

Y355M1-10-90 Y280S-4-75 Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-132 |

33hpa

(-0.097MPa) |

4520

3750 3150 3380 3700 4090 4550 |

75.3

62.5 52.5 56.4 61.2 68.1 75.8 |

1820 |

| 2BE1-353 | 590 (direct)

390 (V-belt) 425 (V-belt) 464 (V-belt) 530 (V-belt) 560 (V-belt) 620 (V-belt) 660 (V-belt) |

121

63 72 85 95 110 133 152 |

Y355L2-10-160

Y280S-4-75 Y280M-4-90 Y315S-4-110 Y315M-4-110 Y315L1-4-132 Y315L1-4-160 Y315L2-4-185 |

33hpa

(-0.097MPa) |

5300

3580 3700 4100 4620 5000 5500 5850 |

88.3

59.7 61.7 68.3 77.0 83.3 91.7 97.5 |

2300 |

| 2BE1-355 | 590 (direct)

390 (V-belt) 420 (V-belt) 464 (V-belt) 523 (V-belt) 590 (V-belt) 660 (V-belt) |

136

75 80.8 95 113 136 182 |

Y355L2-10-160

Y280M-4-90 Y280-4-90 Y315S-4-110 Y315M-4-132 Y315L1-4-160 Y315L2-4-200 |

33hpa

(-0.097MPa) |

5700

4180 4260 4850 5230 6000 6510 |

95

69.7 71 80.8 87.1 100 108 |

2450 |

| 2BE1-403 | 330 (V-belt)

372 (V-belt) 420 (V-belt) 472 (V-belt) 530 (V-belt) |

98

110 131 160 213 |

Y315M-4-132

Y315M-4-132 Y315L1-4-160 Y315L2-4-200 Y355M2-4-250 |

33hpa

(-0.097MPa) |

4860

5400 6470 7380 8100 |

81

90 107.8 123.0 135.0 |

3750 |

| 2BE1-405 | 330 (V-belt)

372 (V-belt) 420 (V-belt) 472 (V-belt) 530 (V-belt) |

100

118 140 170 216 |

Y315M-4-132

Y315L1-4-160 Y315L2-4-185 Y315L2-4-200 Y355M2-4-250 |

33hpa

(-0.097MPa) |

6000

6700 7500 8350 9450 |

100.0

111.7 125.0 139.2 157.5 |

3900 |