What is a Cryogenic Pump?

Cryogenic Pump of Overview

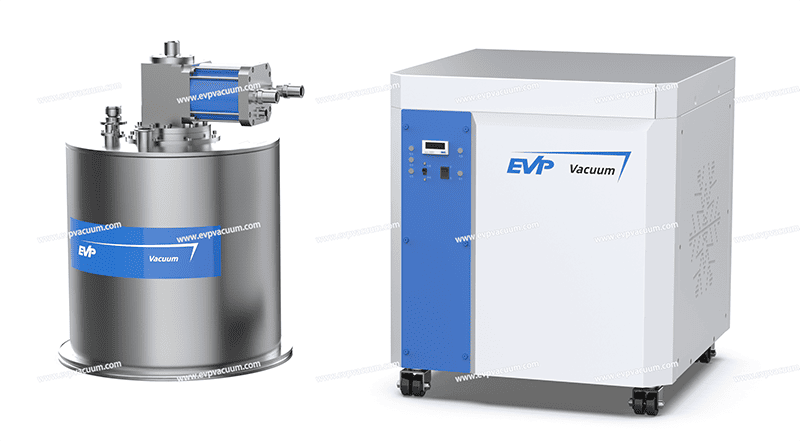

A cryogenic pump is a type of pump that uses a low-temperature surface below 20K to condense gas molecules for pumping, and is currently the highest limit vacuum pump. It is mainly used in large-scale vacuum systems, such as high-energy physics, preparation of superconducting materials, aerospace simulation stations, etc., which require high cleanliness, no pollution, high pumping speed, high vacuum, and ultra-high vacuum. Cryogenic pump, also known as condenser pump or cryogenic pump. According to their working principles, they can be divided into low-temperature adsorption pumps, low-temperature condensation pumps, and refrigeration low-temperature pumps. The first two types of pumps directly use low-temperature liquids (liquid nitrogen, liquid helium, etc.) for cooling, which are costly and usually only used as auxiliary pumping methods; The cryogenic pump of a refrigeration machine is a pump that uses the deep low temperature generated by the refrigeration machine to extract air. Its basic structure is shown in Figure 1. On the first stage cold head of the refrigeration machine, there are radiation screens and radiation baffles, with a temperature of 50-77K, used to condense and extract gases such as water vapor and carbon dioxide, while also shielding the thermal radiation of the vacuum chamber, protecting the second stage cold head and cryogenic plate; The cryogenic plate is installed on the second stage cold head at a temperature of 10-20K. The smooth metal surface on the front of the plate can remove gases such as nitrogen and oxygen, while the activated carbon on the back can adsorb gases such as hydrogen, helium, neon, etc. By the action of the bipolar cold head, the purpose of removing various gases can be achieved, thereby obtaining an ultra-high vacuum state.

Cryogenic Pump Figure 1

As a capture pump, a cryogenic pump can be used to capture various harmful or flammable and explosive gases, causing them to condense on the refrigeration plate to achieve the purpose of pumping. However, after working for a period of time, the low-temperature exhaust capacity of the low-temperature pump will decrease, so it must be “regenerated” by removing the low-temperature condensation layer. The following requirements must be followed during regeneration:

(1) Once regeneration processing begins, it must be thoroughly removed. This is because local heating can cause a large amount of condensed water vapor on the shielding plate to transfer to the internal cryogenic suction plate, seriously damaging the pumping capacity of the cryogenic pump.

(2) During regeneration, the condensation layer should be stably evaporated, and the gas pressure in the system must not exceed the allowable value. Otherwise, when removing flammable and explosive gases such as hydrogen, there is a risk of explosion once they leak into the air.

(3) During regeneration, it is necessary to strictly prevent hydrocarbons from the front stage pump from entering the low-temperature pump and contaminating the suction surface. Therefore, the pumping time is required to be as short as possible.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)