Why does my vacuum pump creak or make noise?

Dirty and noisy

Rotary vane vacuum pumps are known for their extremely high ultimate basic pressure and economical service. They have a rotating cylinder and sliding blades located far away from the middle of the cylindrical chamber. As the blades pass through the inlet, the volume expands and gas enters. As the blades continue to rotate, the inlet eventually closes. From there, the gas volume decreases, causing the pressure to increase until the outlet opens again, at which point the gas can escape the chamber.

Due to the fact that rotary vane vacuum pumps are powered by a rotating rotor and have many moving parts, they generate a lot of noise. When reaching the lowest pressure level, the pump also makes a creaking sound. In most cases, these pumps are dirty. The space between the pump chamber wall and the blades is sealed, forming a layer of oil. Unless preventive measures are taken, this oil may transfer from the pump to the sample chamber. Over time, the pump can also leak. Blowing out seals can lead to more serious problems, such as oil spills becoming viscous and difficult to clean.

Rotary vane vacuum pumps are durable and reasonably priced. There is a reason why these pumps can be found in the global physics department. They are easy to maintain, especially in the field of experimental physics. If repair work is needed, experienced technicians should be able to handle it on site.

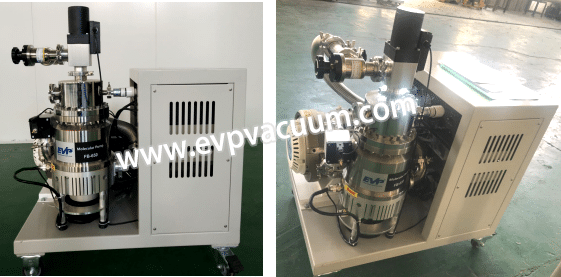

The design of turbomolecular pumps varies, but most modern equipment is oil-free and requires almost no maintenance between bearing replacements. These pumps operate in the same way as small jet engines. They have various rotating turbine blades that quickly rotate, transferring gas from the pump’s inlet to outlet. The pump’s speed can reach up to 90000 RPM.

Why does the turbo pump make such a loud noise?

One of the reasons why turbo pumps become noisy is due to bearings. When the bearing life expires, the turbo pump will begin to emit sharp whistling sounds. This indicates that the bearing is about to fail and should be replaced.

Clean and quiet

Dry vortex pumps, especially modern designed vortex pumps, have extremely low decibel ratings during normal operation. Dry vortex discs have a set of interlocked spirals instead of a rotating shaft with sliding blades. Due to their spiral design, the pump is more efficient. This means they can create a seal without oil, which is why they tend to be clean. They are actually not very noisy. When in use, they make a creaking sound, but not the loud sound of a rotary vane pump. Of course, they are much more expensive than rotary pumps and cannot exceed milliTorr pressure. Therefore, these pumps can be used wherever you may need them.

Low temperature pumps typically used for high vacuum applications are definitely cleaner than turbo pumps. However, they can still be considered noisy. These pumps guide cold air to pump gas. The gas circulates in the liquefied area. Then, the gas is used to cool the components. The components stick to the vacuum chamber from there. In some cases, materials such as charcoal may be coated to increase the total surface area. If the boiling point of the gas is higher than the temperature of the coolant, it will freeze to the surface, which will cause a decrease in pressure inside the chamber.

These pumps are often used in conjunction with compressors, resulting in loud noise that makes the gas easy to liquefy. Some pumps use helium gas to quickly cool internal components. These pumps are loud and can be heard from a distance. On the positive side, if you can’t hear any noise, you will know that the pump is faulty.

Despite these noises, these pumps will still remain very clean because they cannot bring dust into the vacuum system. These pumps are very expensive, and the compressor and pump are not * * expenses. Obtaining helium gas for the pump can also be very expensive.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)