2BE1-355 pump for bearing and mechanical seal of disassembling process

In the process of assembling bearings and machine seals, most of the water ring pumps produced by EVP are assembled by hoisting (that is, vertically installing the pump), while the maintenance and replacement of bearings and machine seals by users in the later stage are mostly horizontal assembly and assembly & disassemble. Therefore, the following explanations are all based on the general horizontal disassembly process for users to understand.

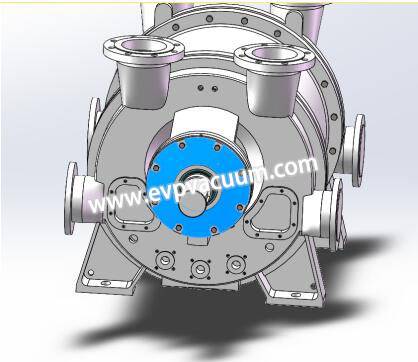

The first step is to remove the blue parts in the Figure 1, please remember to remove the screws on this cover together.

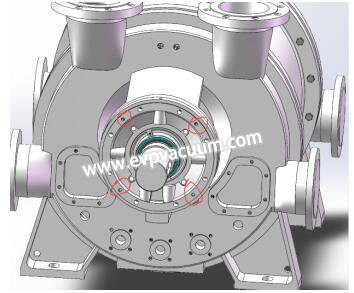

The second step, after removing the cover in Figure 1, you will see the style shown in Figure 2 below. Screw in the four red circles in Figure 2 with bolts, and then pull out the bearing. After the bearing is pulled out, the bearing seat is also removed. After dismantling to this step, the user basically has a very clear understanding of how to operate the next change.

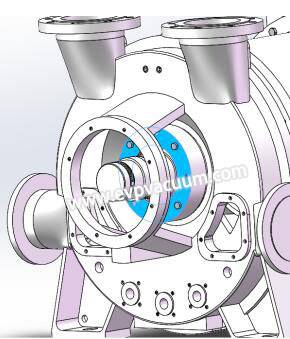

The third step, after the bearing seat is removed, the component marked blue in Figure 3 is the mechanical seal. Unscrew the screws on the mechanical seal, and then pull out the mechanical seal.

Note: For large pumps, if the mechanical seal and bearing are disassembled horizontally, attention should be paid to the fixation of the pump shaft. It is best for the user to use a V-block to support the shaft to avoid the drop of the shaft due to the influence of gravity during the disassembly process. The balance of the clearance in the pump is destroyed early.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)