vacuum pump in the production of ketene of application

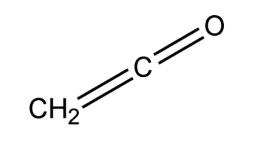

Ketene is an organic compound with a chemical formula of C2H2O. It is the simplest ketene. It is a toxic gas at room temperature and is very unstable. It can only be stored at low temperature. At 0 °C, a polymerization reaction can occur. Ketene is a colorless gas; it has a pungent odor similar to chlorine and acetic anhydride; it is toxic and can cause severe headaches after inhalation; it can be liquefied into a colorless liquid; melting point -151°C, boiling point -56°C.

Ketene is an excellent acylating reagent and one of the indispensable intermediates in organic synthesis. Starting from ketene and diketene, dozens of series of fine chemicals can be developed, which can be widely used in medicine, pesticides and dyes. , organic pigments, spices, food and feed additives, engineering plastics and synthetic fibers and other fields, its development and application prospects are very broad. Especially in recent years, with the development of a new process for synthesizing chloroacetyl chloride by chlorination of ketene and the development of other downstream products such as acetylacetone and sorbic acid, ketene has been in short supply.

There are many methods for preparing ketene. Taking acetic acid as raw material and catalyzing and dehydrating under negative pressure are the main production methods for preparing ketene products at home and abroad. Safe, stable and economical liquid ring vacuum pump is used in the production of ketene. With the continuous progress of technology, the application of liquid ring pump in ketene production has been further optimized.

Cracking: After heating the cracking furnace to a constant temperature of about 800C for 2 hours according to the operating procedures, glacial acetic acid was made into a 95% solution, added to the vaporizer to evaporate into acetic acid vapor, and added to the preheating furnace together with the catalyst triethyl phosphate to preheat. After entering the cracking furnace, cracked into ketene gas.

Separation: The mixed gas of ketene gas, uncracked acetic acid vapor and generated water vapor from the cracking furnace enters the first-stage and second-stage casing condensers for condensing in turn, and the dilute acetic acid is separated from the first-stage and second-stage separators. , the gas from the two-stage separator enters the three-stage tube condenser for further condensation, and the dilute acetic acid is separated, and then the gas is passed through a vacuum pump to absorb various follow-up products of diketene produced in the section or ketene produced in other sections. Apply after acetic acid concentration.

In the process of cracking and separating ketene, the liquid ring pump plays an important role, and the liquid ring pump is an isothermal compression process. Due to the extremely unstable nature of ketene, the waste of materials is greatly reduced. The use of liquid ring pump is safer for production, which greatly avoids the danger of cooling brine entering the system, and greatly reduces the sudden drop of vacuum in the system or even the leakage of ketene caused by the sudden failure of the vacuum pump; in addition, the liquid ring pump is more environmentally friendly, The noise is low, the pollution is small, and frequent maintenance is not required, which reduces the efflux of ketene.

The liquid ring pumps produced by our company have a pumping capacity ranging from 27m3/h to 60,000 m3/h. The 2BE1 and 2BE3 series are commonly used in the production of ketene. For specific selection and quotation, please contact our professional sales team.