Several classic methods to improve vacuum pump performance

It can be seen from the description of the vacuum pump that there are many measures to improve the performance of the vacuum pump. This article only lists several typical methods in the application process.

Regarding the method of improving the performance of the vacuum pump in terms of design, such as the influence of the gap between the pump casing and the end face of the impeller on the performance of the vacuum pump, the change in the speed of the vacuum pump, and so on.

The specific conditions in the application can be used differently, which will play a positive role in improving the performance of the vacuum pump and improving the stability and reliability of the vacuum pump operation.

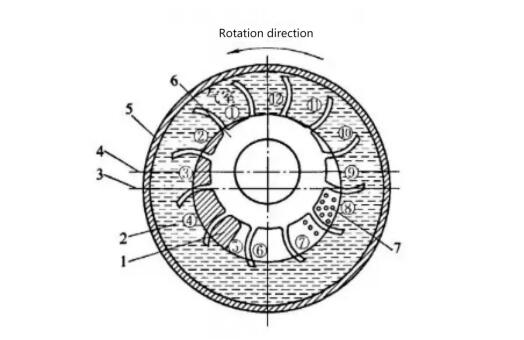

Figure 1, the working principle diagram of the vacuum pump, and the specific workflow will be introduced in detail in the following content:

Figure 01

1.The role of vacuum pump inlet regulating valve

Vacuum pumps are generally used for vacuuming, but not all occasions require the vacuum degree to be as low as possible, and some occasions require control within a certain required vacuum degree range.

If the pressure in the pump cavity of the vacuum pump is too low, severe cavitation will occur in the pump cavity, causing the vibration and noise of the pump to be too large and affecting the use, you can add a vacuum regulating valve in the suction area of the pump.

When the above situation occurs, the regulating valve can be properly opened to alleviate the influence of vibration and noise, or reduce the vacuum degree to meet the required vacuum degree requirement. This is a method for more rational use of vacuum pumps.

2.The role of atmospheric injectors

Any liquid has a vaporization pressure at any temperature. The ultimate vacuum of the water ring vacuum pump is related to the saturated vapor pressure of the liquid circulating liquid in the vacuum pump. The medium with high saturated vapor pressure has a lower ultimate vacuum of the vacuum pump. Conversely, the ultimate vacuum higher.

From Figure 1, we can see that the vacuum pump forms a vacuum state in the cavity during the suction process of 1-5. According to Dalton’s law, the liquid ring is stirred by the impeller. We think that the cavity 1-5 The sum of the saturated vapor pressure of the filled liquid circulation and the pressure of the suction gas.

When the amount of inhaled gas is zero, the suction pressure of the vacuum pump is the lowest and the vacuum degree is the highest. At this time, the pressure in the 1-5 chamber is the saturated vapor pressure of the liquid ring.

Therefore, the minimum absolute pressure at the inlet of the vacuum pump must be the saturated vapor pressure value of the liquid ring medium at this temperature.

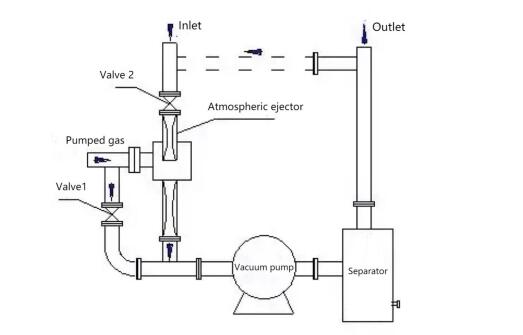

Figure 2 Principle of Atmospheric Ejector

If the liquid ring medium remains unchanged, we can increase the vacuum degree of the liquid ring pump by installing an atmospheric injection device at the inlet of the vacuum pump, as shown in Figure 2.

When the vacuum pump just starts to suck the gas to be pumped, the vacuum degree of the gas to be pumped is low at this time, we open the valve 1 in Figure 2 and close the valve 2.

When the pressure of the pumped gas becomes lower and drops to 60~30mmHg, open valve 2 and close valve 1.

At this time, because the system pressure of the pumped gas is low, the large pressure difference makes the outside atmosphere or the gas from the gas-liquid separator enter the atmospheric injector from valve 2, and the gas will quickly pass through the nozzle of the atmospheric injector, and the gas will flow through the nozzle. The speed of the internal airflow is further accelerated, and the pressure behind the nozzle is rapidly reduced, so that a high vacuum behind the nozzle is formed.

Since the low-pressure chamber behind the nozzle communicates with the pumped gas, the pumped gas will be further pumped away, and a higher vacuum degree will be formed in the cavity of the pumped gas, and the pumping capacity of the vacuum pump will increase, and the vacuum in the vacuum pump will increase. On the contrary, the speed will be reduced, which will effectively improve the problems of cavitation, vibration and noise caused by the low pressure in the pump chamber.

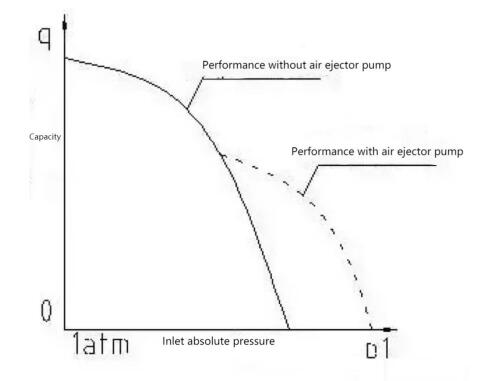

Figure 3 is a change diagram of the vacuum degree of the pumped system after adding the atmospheric ejector. It can be seen from the figure that after adding the atmospheric ejector, the vacuum degree of the pumped system will become very high, but the power of the pump basically does not change, indicating that The atmospheric ejector acts to increase the ultimate vacuum of the pumped system, and the shaft power of the pump remains unchanged.

Figure 3 The change of vacuum pump performance by atmospheric ejector

It should be noted that the function of the atmospheric ejector is not only to increase the vacuum degree of the pumped system, but when the pump works under very low pressure, cavitation will occur in the pump cavity, which will increase the vibration and noise of the pump.

The use of atmospheric ejectors can not only make the vacuum pump not need to work under very low pressure, but also is very important to improve the stability of the vacuum pump operation.

When we use water as the working fluid of the liquid ring pump, when the water temperature rises to 30°C and the vacuum degree is around 8kPa (abs), cavitation will occur in the pump chamber.

If the atmospheric ejector is connected in series at the suction port of the pump, the pump will run stably within 1.3~2 kPa(abs), at this time, the operating pressure in the vacuum pump chamber is about 13 kPa(abs), and cavitation does not occur.

Atmospheric ejectors are driven by the atmosphere or the exhaust gas from a vacuum pump without any power.

3. Influence of Supplementary Working Fluid System on the Performance of Vacuum Pump

Replenishment of working fluid must be carried out continuously. But how to replenish the working fluid and how to determine the flow and pressure of the replenishing working fluid can improve the performance of the vacuum pump.

4.Increase the vacuum degree by lowering the temperature of the working fluid

It is known that the vaporization pressure of the liquid has a great relationship with the temperature of the liquid. High temperature and high vaporization pressure lead to low vacuum degree of the pump, so reducing the temperature of the working fluid is beneficial to improve the vacuum degree of the pump.

For the working fluid with higher temperature, we need to increase the vacuum degree of the vacuum pump by reducing the temperature of the working fluid through heat exchange.

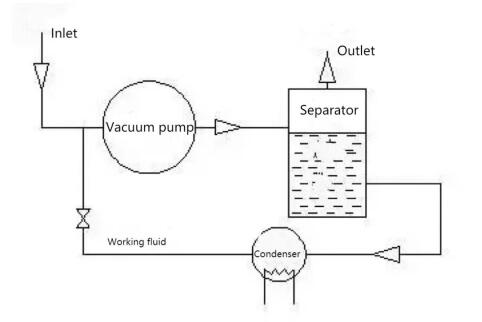

As shown in Figure 4, we take water as an example. The saturated vapor pressure of water at 20°C is 0.0233bar, and the saturated vapor pressure of water at 50°C is 0.1234bar, and the saturated vapor pressure has increased by more than 5 times.

Figure 4 Use a heat exchanger to reduce the temperature of the working fluid

The temperature of the liquid ring vacuum pump has a great influence on the gas volume of the pump. The higher the vacuum degree, the more obvious this effect is. As the water temperature rises, the gas volume decreases. The quantitative change can be calculated by the following formula:

Qt=Q15*(P1-Pt)/(P1-P15) (1)

Note:

Qt—air volume when the water temperature is t°C (m3/min)

Q15–gas volume when the water temperature is 15°C (m3/min)

P1—water ring pump suction pressure (mmHg)

Pt—saturated vapor pressure when the water temperature is t°C (mmHg)

P15–The saturated vapor pressure when the water temperature is 15°C (mmHg)

It can be seen that the liquid ring temperature of the water ring pump has an influence on the vacuum degree and gas volume of the vacuum pump, so it is very necessary to reduce the liquid ring temperature of the water ring pump.

5.Use different working fluids to improve the performance of vacuum pumps

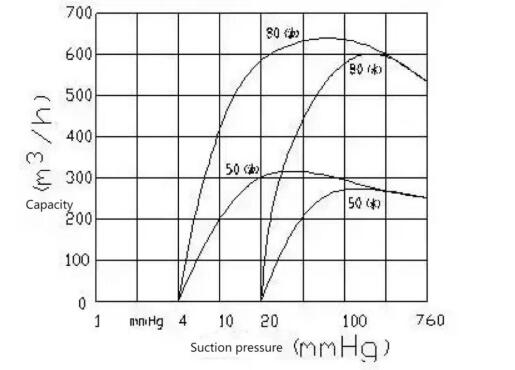

The vaporization pressures of water and oil are quite different at the same temperature. We use water and oil as the liquid ring of the water ring pump respectively, and the diameters of the pumps are 50mm and 80mm respectively.

It can be seen from Figure 5 that at the point above the pressure of 300mmHg, the water as the liquid ring of the vacuum pump and the oil as the liquid ring of the vacuum pump basically have the same pumping capacity, but at the pressure point below 300mmHg, we see the oil ring The inhaled air volume of the water ring is larger than that of the water ring, and the lower the pressure, the more obvious.

And the ultimate vacuum pressure of the water ring is 20mmHg, while the ultimate vacuum pressure of the oil ring is about 4mmHg, which is quite different.

It can be clearly seen from the above figure that the saturated vapor pressure of the liquid ring is closely related to the improvement of the ultimate vacuum of the liquid ring pump.

Figure 5. The performance curve of the relationship between the air volume and pressure of the vacuum pump

6.Increase the performance of the vacuum pump by replenishing fluid from different locations

See Figure 1, in the vacuum pump chamber, ①~⑤ are low-pressure chamber areas in the pump body, and ⑦~11 are high-pressure chamber areas. If the liquid replenishment port is located in the low-pressure area, the external liquid supply can be through the self-priming method of the pump itself. To achieve fluid replacement, the requirement for fluid replacement pressure is low.

If the liquid is replenished in the high-pressure chamber, the pressure of the liquid replenishment must be greater than the pressure in the pump chamber to replenish the liquid in the pump chamber. Otherwise, the working fluid will not be replenished in time, which will cause the gas to flow back from the compression chamber to the suction chamber, affecting the performance of the vacuum pump.

After several verifications, it was found that using the self-priming method of the pump to replenish the liquid will reduce the performance of the pump, because the pump replenishes the liquid at the suction chamber or replenishes the liquid from the end face of the impeller, and the working fluid has been working for a period of time (from the working When the liquid compresses the gas, it is the starting point), that is, there is a certain loss of energy, and at this time, the fluid replenishment will cause impact loss to the liquid ring, which also reduces the effective work of the working fluid on the gas and consumes a part of energy.

If the replenishment fluid is placed at the position of the 11th air chamber in Figure 1, the replenishment fluid will obtain sufficient energy and participate in the next round of suction and exhaust with almost no energy loss. Performance is good.

However, it is not that the higher the pressure of the liquid infusion, the better. It has been verified that the pressure is generally 1~1.5bar. Both suction volume and discharge pressure are reduced.

At the same time, the amount of liquid delivered by the pump increases, so the shaft power will increase, the efficiency of the pump will decrease, and at the same time, vibration and noise will be generated, and a large amount of water will be periodically discharged from the exhaust port of the pump.

7.Reasonably replenish the working fluid and improve the performance of the vacuum pump

Under what circumstances is the supply of working fluid the most reasonable, so that the vacuum pump is in an optimal operating state, the amount of supply fluid can be determined by calculation.

Some people often think that only the power loss part is converted into heat, which is not the case for dry pumps that transport gas, which converts all shaft power into heat.

Through the calculation, the vacuum can be replenished clearly. This reasonable replenishment can give full play to the role of the liquid ring, and discharge the heat generated by the compressed gas of the vacuum pump out of the pump chamber in time, so as to ensure that the temperature of the liquid ring of the vacuum pump will not rise sharply. , effectively seal the gap between the impeller of the liquid ring pump and the pump body, improve the volumetric efficiency of the vacuum pump, timely replenish the working fluid discharged from the pump chamber with the gas, and lubricate the shaft seal, while improving the operation reliability of the vacuum pump. smoothness and efficiency.

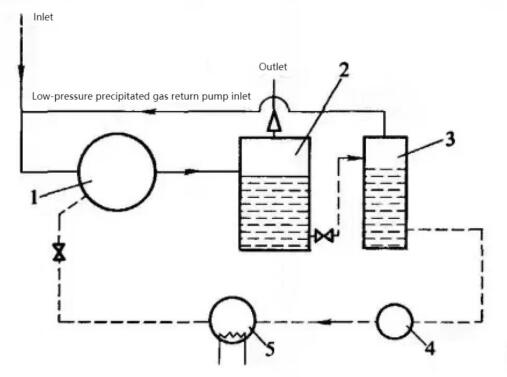

8.Special gas-liquid separation device

The outstanding advantage of the liquid ring pump is that it can transport toxic, harmful, flammable and explosive gases without causing harm to the environment and people.

Another outstanding advantage is that the compression process of the liquid ring pump can be considered as isothermal compression, so that the compression of dry flammable and explosive gases will not cause the danger of combustion and explosion.

However, if the pumped gas is dissolved in the liquid ring, the pumping capacity of the liquid ring pump will change. The easier it is to dissolve the gas in the liquid ring, the greater the change in gas volume and the less the gas pumped, so for this situation , in order to recover the gas in the liquid ring as much as possible, the gas-liquid separator can be set as the structure shown in Figure 6.

It can be seen from the figure that the gas discharged from the vacuum pump first enters the first-stage gas-water separator, and the discharged gas is discharged from this separator, and the working fluid full of dissolved gas is transported to the next-stage low-pressure gas-water separator .

Due to the reduction of pressure, the gas dissolved in the liquid is released, and the released gas is sent to the inlet of the pump to participate in the circulation.

Due to the recycling of the working fluid, the pressure of the liquid separated from the next stage separator becomes very low, and it is necessary to use a pump to boost the pressure and then replenish the vacuum pump.

Figure 6 Special separation of dissolved gases

(Note: 1. Vacuum pump 2. Air-water separator 3. Low-pressure air-water separator 4. Pump 5. Cooler)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)