2bv2-060 Series Liquid Ring Vacuum Pump

1. Liquid ring vacuum pump of working principle:

2bv2-060 liquid ring vacuum pump will heat the working liquid ring due to its work, and some water and gas will be discharged together. Therefore, during the working process, it is necessary to continuously supply water to the vacuum pump to cool and supplement the water consumed in the vacuum pump, so as to meet the working requirements of the pump.

When the gas discharged from the liquid ring vacuum pump is no longer used, a gas water separator is connected to the exhaust port of the liquid ring vacuum pump. After the waste gas and part of the water are discharged into the gas water separator, the gas water is separated, the gas is discharged from the exhaust pipe, and the left water is supplied to the vacuum pump for further use through the return pipe. With the extension of working time, the temperature of working water will continue to rise. At this time, it is necessary to supply cold water from the water supply pipe to reduce the temperature of working water and ensure that the vacuum pump can meet the required technical requirements and performance indicators.

When the liquid ring vacuum pump is used as a compressor, the exhaust port of the vacuum pump is connected with a gas-water separator, and the gas-water mixture enters the gas-water separator and then automatically divides. The gas is delivered to the required system by the exhaust pipe, and the working water enters the liquid ring vacuum pump through the separator. When compressing gas, the working water is very hot. The water is discharged from the vacuum pump exhaust port, and the temperature will become higher. The water supply pipe should continuously supply cold water to supplement the discharged water, and at the same time play a cooling role, so that the working water temperature will not be too high, so as to ensure the performance of the compressor, meet the technical indicators and meet the process requirements.

2.Liquid ring vacuum pump of structure description:

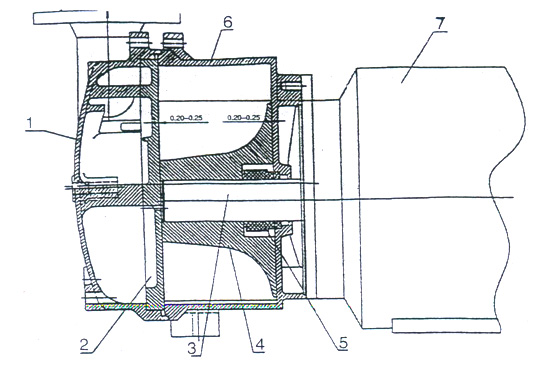

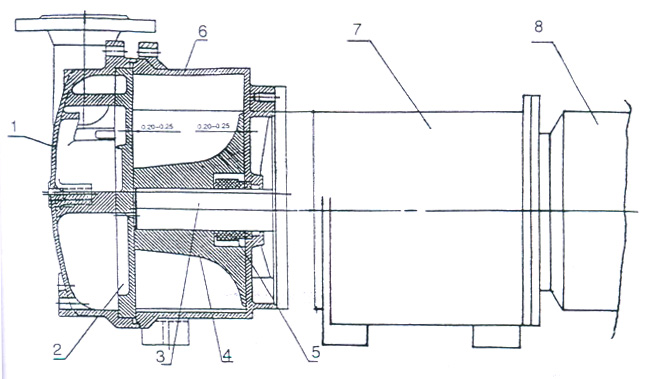

The structure of 2BV liquid ring vacuum pump is shown in Fig. 1, Fig. 2 and Fig. 3

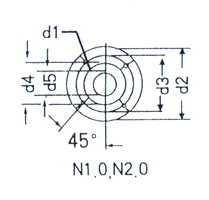

|

|

|

|

|

Figure 1 2BV-2060 / 2061/2070/2071 liquid ring pump structure |

Figure 2 2BV-5110 / 5111/5121/5131/5161 liquid ring pump structure |

Figure 4 2BV-6110 / 6111/6121/6131/6161 liquid ring pump structure |

|

1. pump cover 2. disc 3. flat key 4. impeller 5. mechanical seal 6. pump body 7. motor |

1. pump cover 2. disc 3. flat key 4. impeller 5. mechanical seal 6. pump body 7. motor |

1. pump cover 2. disc 3. flat key 4. impeller 5. mechanical seal 6. pump body 7. motor |

3. Liquid ring vacuum pump of product description:

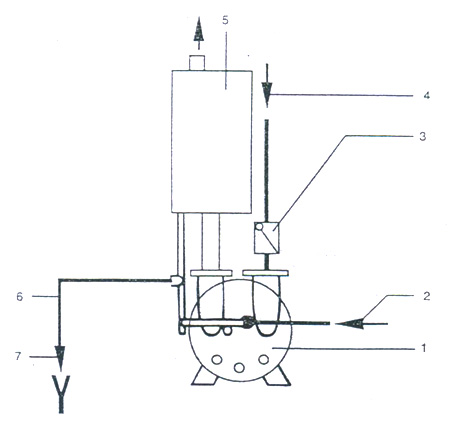

2BV vacuum pump and compressor system is composed of vacuum pump (compressor), motor and air-liquid separator pipeline, as shown in Figure 4.

|

|

|

Figure 4 Schematic diagram of 2BV liquid ring pump system |

|

1. 2BV vacuum pump 2. liquid supply pipe 3. check valve 4. suction pipe 5. air-water separator 6. exhaust pipe 7. overflow pipe |