Oil free vacuum pump in oil production system

The lifting methods widely used in oilfield production mainly include rod pump, electric submersible centrifugal pump, oil-free piston vacuum pump and screw vacuum pump. This paper mainly talks about the application of oil-free vacuum pump in oil production system.

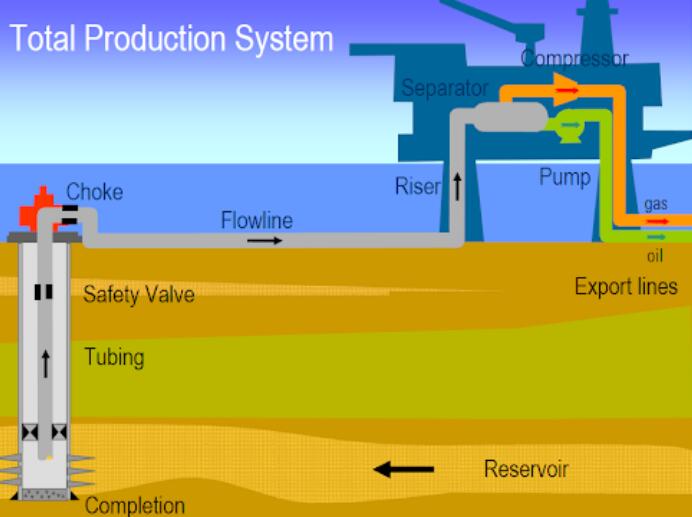

Subsea oil production system is a kind of modern underwater wellhead equipment and oil gathering facilities. The most basic requirement of subsea production system is to install as many production facilities as possible on the seabed. There are two basic ways: one is wet Christmas tree technology, the other is dry wellhead equipment. In the warm oil production system, each well is completed according to the usual method, and then it is connected with the manifold control group by the outlet pipe, and the crude oil is transported to the production platform. The main feature of dry oil production system is “atmospheric chamber”, which is respectively installed on the wellhead chamber of each well and manifold control group. Wet production facilities require divers who can swim, while dry systems require a support vessel and subsea service bay.

Compared with sucker rod pump, oil-free vacuum pump oil production system has the following advantages in addition to sand production and heavy oil wells

1. Energy saving, the thicker the oil, the more significant the energy saving and consumption reduction;

2. There is no air lock and demulsification;

3. The swabbing is continuous and stable, and there is no pressure excitation in the reservoir;

4. Without sucker rod, the loss caused by wear of rod and tube is eliminated, and smaller size tubing can be used;

5. It can be used in inclined well, directional well and horizontal well

6. Small floor space, no leakage and noise at wellhead, and simple daily management;

7. Increase the pump depth and displacement;

8. The heating of the unit under the pump plays the role of heating under the pump.

Precautions for using oil-free vacuum pump:

1. Choose the power supply and capacitor that match with the product name plate correctly. When the power supply voltage exceeds the service range or the voltage fluctuates greatly, please add voltage regulator before use.

2. This product uses the environment temperature – 10 to + 40 ℃, altitude is not higher than 1500m, more than 1500m use plateau vacuum pump. When using, it should be placed in a ventilated and clean place.

3. Select appropriate intake filter muffler and clean or replace it regularly.

4. The medium used in this product is air. If you need to use other media, please consult the technician.

After the discussion on the application of oil-free vacuum pump in oil production system, it can be confirmed that the oil-free vacuum pump is equipped with rubber damping foot pad, which is more stable in operation, small in size and beautiful in appearance. It is equipped with overload protector and will not be burnt out due to overload, so it can be better applied to oil production system. Moreover, it has made great progress in basic research, manufacturing and oilfield application research, and formed its own unique advantages.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)