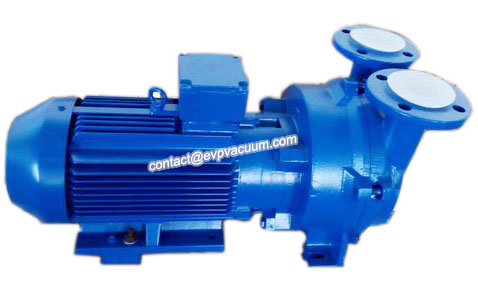

2BV2 061 water ring vacuum pump

2BV2 061 water ring vacuum pump is suitable for extracting gas and water vapor. The suction pressure can reach 33 mbar absolute pressure (97% vacuum degree). When the suction pressure of vacuum pump is lower than 80mbar for a long time, the pump shall be protected by connecting the cavitation protection pipe. If equipped with air ejector, the suction pressure can reach 10mbar, and the ejector can be directly installed on the vacuum pump. When used as a compressor, the maximum pressure is 0.26mpa (absolute pressure).

The saturated vapor pressure of the liquid ring has a decisive influence on the ultimate vacuum of the pump. If the water used in the water ring pump is used as the working fluid, the saturated steam pressure of the water ring pump is 12-18torr at 15-20 degrees, then the theoretical (i.e. no loss, no actual) limit vacuum pressure of the water ring pump is 12-18torr of the saturated steam pressure of the working fluid.

In addition, the cavitation and stability of 2BV2 061 water ring vacuum pump when it operates near the limit vacuum make the effective working range of the pump narrow, and the effective vacuum degree also decreases.

In order to reach the limit vacuum pressure of 1-5 torr or lower, one (or 2-3) air jet vacuum pump can be connected in series in front of the water ring vacuum pump to form a high vacuum unit.

Air jet vacuum pump (hereinafter referred to as air pump) is a kind of jet pump connected to the inlet of water ring pump. Valve 10 is a valve that controls the pressurized gas on the atmosphere or gas separator to enter the suction pipe of the pump.

Open and close the valve before operation. Start the water ring pump, at this time, the gas of the pumped system is continuously pumped out by the water ring pump through the intake pipe and valve. When it is 20 ~ 30torr higher than the limit vacuum pressure of the pump, the valve can be closed and opened. At this time, the pressure difference between the external atmosphere (or pressure gas) and the intake pipe is very large. Under the effect of this pressure difference, the atmosphere (or pressure gas) runs sharply to the suction pipe of the dry boat. Through the nozzle of the large air pump, the air flow speed is further increased, so the pressure is rapidly reduced, so as to form a higher vacuum in the nozzle (obviously higher than the limit vacuum of the pump), so that the gas of the pumped system will continue to be drawn into the pump.

It can be seen that when the valve is opened near the limit vacuum degree of the pump, the mixed gas from the atmosphere (or pressure gas) and the pumped gas enters the pump. At this time, the air volume of the water ring pump will obviously increase, but the pressure in the pumped system is lower than the limit vacuum pressure of the pump. Therefore, water ring air pump can only improve the vacuum degree of the pumped system, but the vacuum degree of the pump will decrease. Of course, we need to improve the vacuum aromatics in the pumped system. At this time, the vacuum degree of the water ring pump decreases and the air volume increases, which can also achieve good results of avoiding cavitation, reducing noise and power, and working stably.

Water ring vacuum pump can be divided into single stage and double stage, and the difference between single action and double action. The single-stage and double-stage vacuum pumps refer to the stages of their impellers; the single / double action refers to the form of their impellers / casings. The impellers of single-stage and double-stage vacuum pumps experience one suction / discharge of gas in one revolution; the impellers of double-stage and double-stage vacuum pumps experience two suction and discharge of gas in one revolution.

2BV2 061 water ring vacuum pump is a crude pumping pump using liquid as working medium. The water ring vacuum pump uses water as working medium, and oil, sulfuric acid and acetic acid can also be used as working medium. Industrial water ring vacuum pump is mostly used.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)