2sk-30 liquid ring vacuum pump

Liquid ring vacuum pump of product overview

2SK series Liquid ring vacuum pumps and 2SK-P1 series two stage liquid ring vacuum pumps – air jet pumps are used to extract air and other non corrosive, insoluble and non solid particles in order to obtain a higher vacuum in closed containers. It is widely used in vacuum evaporation, vacuum concentration, vacuum resurgence, vacuum impregnation, vacuum drying and vacuum smelting in food, knitting, chemical, pharmaceutical and metallurgical industries and electronics. It has the characteristics of high vacuum, high pumping speed in high vacuum area, compact structure, reliable operation and convenient maintenance.

2SK series is suitable for the working condition with suction pressure lower than -0.08MPa. 2sk-p1 series is suitable for working conditions with suction pressure lower than – 0.096mpa. When equipped with an atmospheric pump, the limit vacuum degree can reach – 750mmhg. The working vacuum range is -0.03-0.08mpa.

Liquid ring vacuum pump of working principle

2SK series liquid ring vacuum pump is a two-stage single acting liquid ring vacuum pump. It uses the structure of the pump shell and the impeller which are installed concentrically. When the impeller is rotating, the direct vacuum pump forms a liquid ring which is eccentric with the impeller. It is filled with water between the blades. With the rotation of the impeller, it constantly makes periodic reciprocating motion between the blades. It changes the volume in the middle of the blades and the volume in the fixed suction Under the corresponding coordination of the air port and the exhaust port, the suction, compression and exhaust functions are completed. The two-stage function is that the gas discharged from the first stage exhaust port is inhaled by the second stage suction port, and then discharged through the second stage compression. The second stage function is to reduce the first stage exhaust pressure, so as to improve the first stage suction limit vacuum degree.

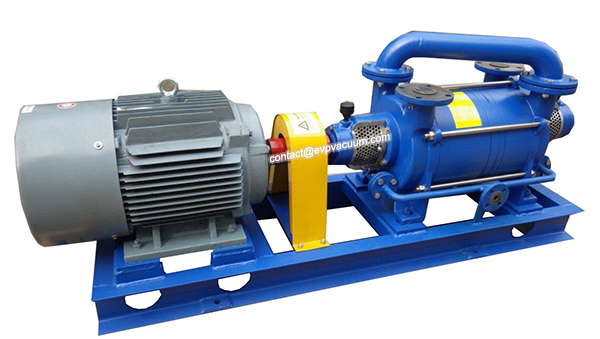

The two-stage liquid ring vacuum system of this model is made into a two-stage pump in series with coaxial phase. The ventilation channel between the two stages is composed of an intermediate basin and a connecting pipe, so the structure is relatively compact. The rotating part is composed of a shaft and two-stage impeller, the fixed part is composed of the inlet and outlet air frame, two pump rings, air distribution plate and bearing bracket. The drive of the motor and pump part is installed on a common base with a shaft chatter pump and a motor.

Liquid ring vacuum pump of main features

The 2SK two stage liquid ring vacuum pump has the characteristics of high vacuum and high pumping speed in high vacuum area.

The utility model has the advantages of compact structure, convenient maintenance, wide application range, and can extract various gases including water vapor, inflammable, explosive, a small amount of dust and a small amount of liquid;

The main liquid is used as the working medium, so the maintenance cost is low, and it can work in the worse environment.

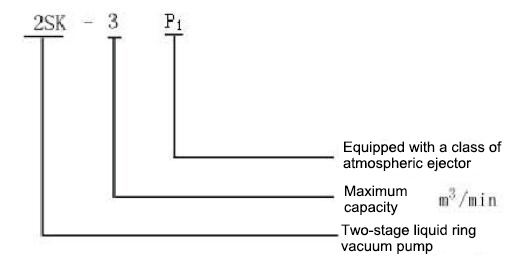

Liquid ring vacuum pump model meaning

2sk-30 liquid ring vacuum pump

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)