EVP SV-series rotary vane vacuum pump upgrade

EVP SV-series rotary vane vacuum pump upgrade

Based on years’ study and researches, EVP engineering team has worked out and promoted an updated SV single stage rotary vane vacuum pump with many improvements. For more details, please see below comparison:

| no. | upgrade item | old type or competition pump | EVP upgraded pump |

| 1 | pump photo |  |

|

| 2 | indicating & danger signs | rotation direction arrow, some with high temperature signs | except for existing signs, adding the signs to indicate the function of each pump,attention signs for maintenance and operation. and all signs in English with danger sketch. |

| 3 | painting | / | optimized the proportion of painting, solidifying solvent, diluent. better |

| 4 | size | size deviation for each batch for several raw material supplier | all raw material purchased from on stable foundry,no deviation on raw material. add dimension measurement inspection on finished components. |

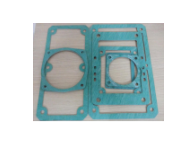

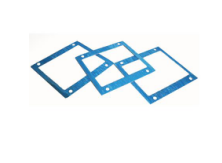

| 5 | sealing |  |

|

| sealed by asbestos gasket with glue on each side to seal the connecting joints | use flurorruber material, it’s pressed on casting parts, the gasket will not move and can be repeatedly used after dissembling. | ||

| 6 | add clean process on finished components | N/A | before finished components assembled, oil tank cleaned by jet pump, especially on each corner of oil tank; together with the rest items, all cleaned by ultrasonic cleaner; |

| 7 | assembled pump | performance test done with small volume of test oil left inside of pump | performance test done, and test oil drained. |

| 8 | suction filer |  |

|

| requiring adapters to connect pump and filter, it increases leaking point. | uniformed, filter can connect to the suction port directly |

If you have any interests, please contact EVP team directly.

Key words: Single stage rotary vane vacuum pump, SV, rotary vane vacuum pump

Edited by: Emily Fu (Shanghai EVP Vacuum Technology Co., Ltd.)

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)