Central feeding Roots blower

The roots blower with central feeding system refers to the roots blower used in the central feeding system. Its working principle is that the central feed system uses roots blower as the source power, and adopts vacuum transmission mode, and conveyed plastic raw material from storage tank to central dehumidification and drying system through centralized pipeline system, and then drier the raw materials to each injection molding machine. The design of “one machine, one pipe” is adopted in the central feeding system to ensure the air of the whole system to transport raw materials and prevent the moisture regain of raw materials after dehumidification and drying. At the same time, it runs stably in each transportation, and there is no material blocking. It can be used with the central dehumidification and drying system, and the conveying pipeline will be cleaned after the dehumidification and drying circulation, so as to ensure that there is no residual granular material in the pipeline, so as to avoid the moisture regain of raw materials, and ensure the consistency of the raw materials added into the injection molding machine. Under the negative pressure of vacuum, the dust from raw materials will be filtered through the dust filtration system, which will help improve the quality of molded products.

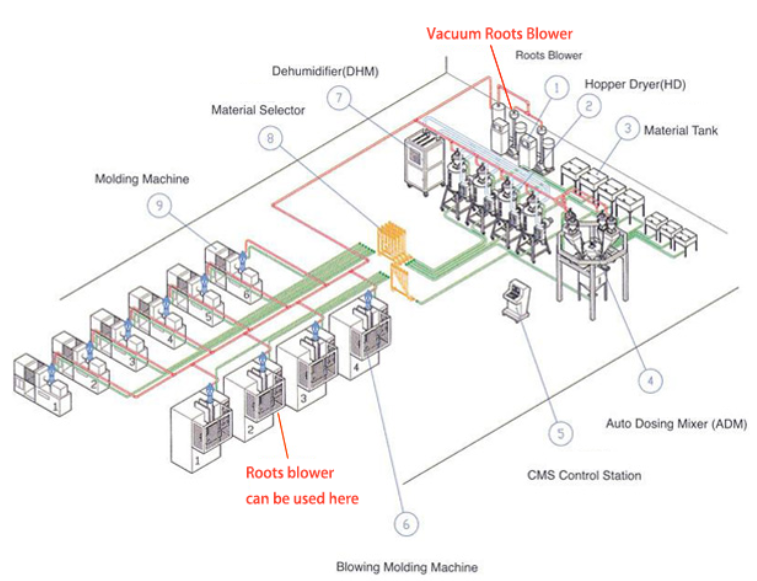

Roots blower in central feeding system of application

The function of Roots blower is to provide power for raw material pneumatic conveying to the molding machine without interruption of raw material.

Why is roots blower used more and more in central feeding system?

1. Roots blower is flexible in application.

As shown in the figure below, roots blower can be installed as a pressure feed roots blower, which is used to blow the materials in the feeder to be transported to the silo through the pipeline; it can also be modified into a vacuum roots blower, whose suction power supply makes the materials transported to the hopper through the pipeline.

2. Roots blower has high efficiency and energy saving of 10%, and its service life is as long as 15 years.

Selection of Roots blower with central feeding

First of all, you need to know whether the system needs to use the function of pressure or suction, and then select the appropriate model according to the parameters such as air volume, air pressure and material proportion. If you encounter difficulties in the selection, please contact us.