Chemical resistant vacuum pump

Chemical corrosion resistant vacuum pump

Vacuum pumps are unmatched in all major chemical and pharmaceutical processes, ensuring full recovery of extraction solvents even under harsh operating conditions. This minimalist design combines traditional durability with reliability. Chemical corrosion resistance vacuum pump divided into liquid ring vacuum pump and screw vacuum pump.

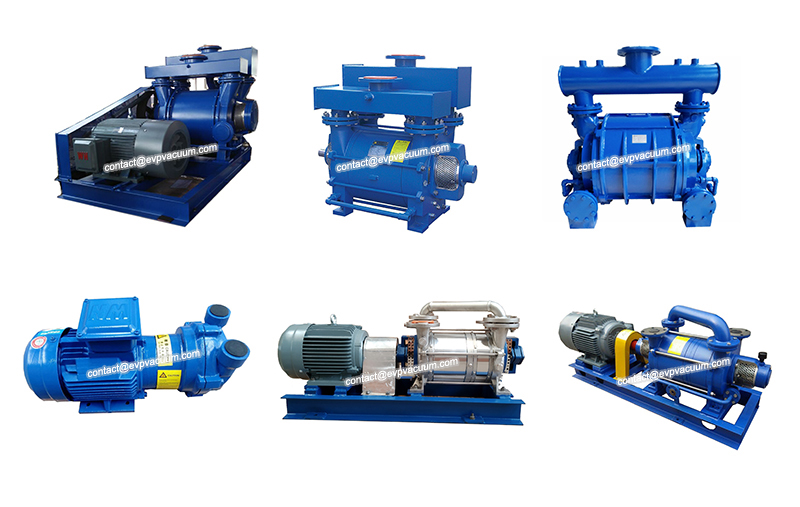

Chemical corrosion resistance liquid ring vacuum pump

Characteristics and application of chemical corrosion-resistant liquid ring vacuum pump

Corrosion liquid ring vacuum pump, specially designed for gas suction acid corrosion, the product is full of nonmetal materials to make, retain the advantages of traditional liquid ring vacuum pump, at the same time has a superior corrosion resistance, fundamentally solves the vacuum equipment frequent damage caused by corrosion, assembly closed-circuit circulation system can realize the working liquid recycle, exhaust gas airtight transportation to achieve environmental emissions standards. The liquid ring vacuum pump with chemical corrosion resistance series includes: 2bv series, 2be1 series, 2be3 series, DLV series, 2sk series, cl series, etc.

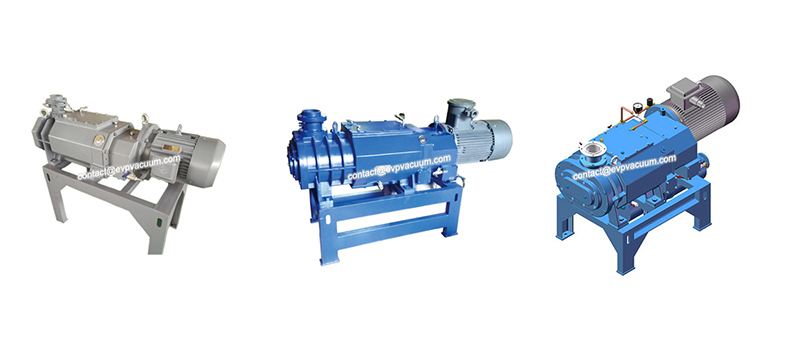

Chemical corrosion resistant screw vacuum pump

Advantages: high vacuum · high pumping speed

Power: 5.5 ~ 22kw

Extraction rate: 50-360l /S

Ultimate pressure: 0.015-0.0075Torr

Chemical corrosion resistance screw vacuum pump performance characteristics

01. No lubricating oil exists in the working chamber, and a clean vacuum can be obtained.

02. There is no oil and gas pollution in the working chamber and the gas is extracted. The recovery efficiency of the process gas is high and the tail gas treatment is convenient. At the same time, the emission of oil and gas and oil smoke is avoided, and the environmental pollution is small.

03. The pump is widely applicable. The surface of pump chamber and screw rotor has anti-corrosion coating, which can be used in bad working conditions.

04. The pump cavity is a gap sealing structure, which is not sensitive to a small number of small particles of dust, and the pump cavity is straight through without a middle baffle structure, so the dust is not easy to deposit in the pump cavity. When the explosion-proof configuration is adopted, it can be used to remove inflammable and explosive gas.

05. The pump chamber temperature can reach more than 100℃, is condensable gas is not easy to condense, and the pump chamber is a straight structure, the exhaust port in the bottom of the pump chamber, the debris in the pump chamber is easy to discharge, so it is appropriate to extract condensable gas.

06. Screw pump simple structure, parts, the number of small, easy maintenance.

07. Fast start, small start current, small impact on the grid when starting, the pump is up to the normal pumping speed.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)