Claw vacuum pump

Claw vacuum pump is not only a kind of Volumetric Vacuum pump, but also a dry vacuum pump. Next let the dry screw vacuum pump manufacturer EVP continue to describe the principle and characteristics of claw vacuum pump.

Claw Vacuum Pumps Types

Claw vacuum pumps, like Roots vacuum pumps and screw vacuum pumps, are non-contact dry vacuum pumps. Generally, in order to achieve a certain compression ratio, rotational speed and dynamic balance, claw vacuum pumps are composed of multi-stage claw rotors in series or Roots rotors in series with multi-stage claw rotors. At present, most of the common types are three-stage claw rotor plus one-stage Roots rotor, or four-stage claw rotor in series. The performance of the Roots-claw type is generally better than that of the full-claw type claw vacuum pump.

In multi-stage claw vacuum pump, according to the form of rotor, phase difference and the difference of separator, it can be divided into spiral type, Anti-claw type and spiral Anti-claw type, and their performances are also different. These forms of difference, dry screw vacuum pump manufacturer EVP is no longer deployed here.

For claw vacuum energy, the higher the rotational speed, the larger the compression ratio. Generally, the rotational speed of claw vacuum pump is 3000r/min, and the limit pressure is 1-10Pa.

2. Claw Vacuum Pump Operating Principle

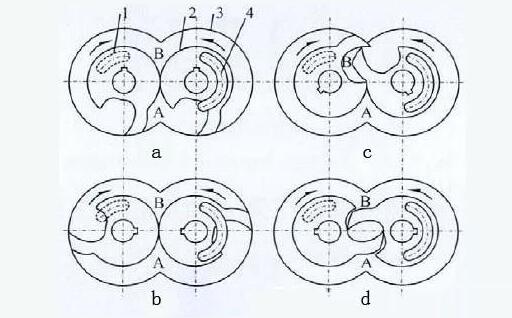

Claw Vacuum Pump Working Principle Diagram

As shown in the figure, the cavity A and the intake port 4 are connected at position A. As the volume of the cavity A increases and the pressure decreases, the gas in the cavity B is gradually compressed under the action of the rotor pair. This is the process of suction.

The volume of cavity A in position B continues to increase and inhale. At the same time, the volume of cavity B gradually decreases under the synchronous reverse motion of the rotor pair. The gas in the position connected with the exhaust port is discharged to the next stage through the exhaust port. This process will continue to the position of figure C. The process of inhalation and exhaust is carried out at the same time, referred to as the suction and exhaust process.

At position C, the maximum volume of cavity A is achieved, the end of inspiration is achieved, while the minimum volume of cavity B is achieved, and the end of exhaust is achieved. The rotor blocked the intake and exhaust ports respectively, and played the role of automatic closure.

At the position of figure d, with the operation of the rotor, the non-exhausted gases in the B-cavity and the inhaled gases in the A-cavity mix together, neither inhaling nor exhausting, which is a transitional process.

Claw vacuum pump achieves the purpose of pumping in the process of continuous repetition.

3. Claw Vacuum Pump Structural Characteristics

1. Claw Vacuum Pump Structure

EVP, a dry screw vacuum pump manufacturer, describes its operation principle simply with the illustration of a single-stage claw vacuum pump. But in practice, claw vacuum pumps are mostly multi-stage. Rotor pairs are installed on two parallel axes. Stage spacers are required to be separated into separate pump chambers between different stages, and there are suction and exhaust passages. The structure is more complex.

2. Claw Vacuum Pump Characteristic and Application

In the process of describing the operation principle, we have learned that the claw vacuum pump can compress gas in operation, and the rotor has the function of self-opening and closing valve in the process of rotation, which can achieve high compression ratio and volume efficiency, and ensure high pumping speed under low power consumption. The type of pumped gas has little influence on the compression ratio, and the clearance between the rotor and the pump body can also ensure the smooth removal of small particles.

Generally speaking, the claw vacuum pump has the following main characteristics:

(1) There is no lubricant in the pump chamber and no oil return.

(2) Clean exhaust, no pollution to the pumped containers and gases, and the pumped gases can be recycled to reduce consumption and emission reduction;

(3) The airflow in the pump chamber moves vertically, and a small amount of particulate matter is easily removed under the action of gravity.

(4) The non-contact pumping element can realize high-speed operation.

(5) The rotor pair is suspended in the pump chamber, and there is no contact between the rotor pair and the pump chamber. It has no friction and long service life.

However, due to the existence of spacers at all levels and the independent existence of each pump chamber, multi-stage claw vacuum pump also has the shortcomings of long and curved airflow passage, difficult assembly and disassembly of rotors and shafts at all levels, and complex clearance treatment between rotors and spacers and pump bodies.

As a dry vacuum pump, claw vacuum pump can be used in semiconductor, chemical industry, nuclear industry, film, instrument, medicine, biopharmaceuticals, food and other fields, and can be used as a gas delivery pump.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)