Vacuum Pump Introduction

As for the liquid ring vacuum pump, I believe all of you here know something about it. There are many manufacturers of vacuum pumps in China, so I will not list them one by one. As for the control of liquid ring vacuum pump, the first point is the control of water quantity and the second point is cavitation.

Vacuum pumps are used in many industries, such as disinfection cabinets in hospitals, beer industry, canned drinks and so on. There are many types of vacuum pumps, one is water-ring pump (circulated by water level medium), the other is dry pump, such as screw pump, Roots pump. Water ring pump is also called rough pump, because it requires a wider range of media. Like screw vacuum pump and Roots pump, they are widely used in the electronic industry. It adjusts the gap relatively small. If the clearance between the two pumps is not adjusted well, it is also very easy to be damaged (Note: The clearance adjustment is aimed at adjusting the distance between the rotor and the cylinder when assembling the vacuum pump cylinder, which is generally in the range of 0.1-0.5 wires. Correct adjustment of the clearance is conducive to the service life of the vacuum pump and effectively reduces the unconventional friction between the vane and the cylinder body of the vacuum pump! Generally speaking, vacuum pump vacuum is not high, noise, oil leakage, smoke injection are related to vacuum pump clearance! Clearance is also one of the core technologies of vacuum pumps. In petroleum industry, screw vacuum pump is used to extract volatile gas above the liquid surface.

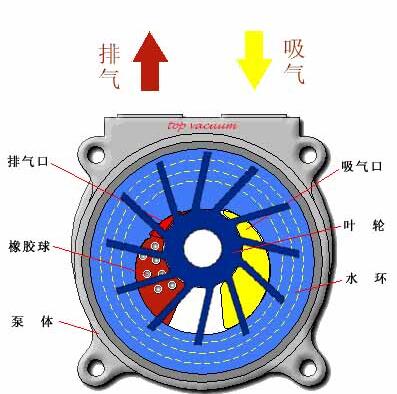

The structure of water ring vacuum pump is relatively simple. There are two discs on both sides, diaphragm on the side and impeller in the middle. Water ring vacuum pump can be used for vacuum pumping and desulfurization in power plants. In alumina industry, centrifuges can not be used for various reasons. Vacuum pumps can be used to dry aluminium powder.

The situation of vacuum pump will be introduced to you here, I am more interested in electrical aspects, such as PLC control. As a after-sale, I often encounter this kind of problem in my work, so this is my future study direction. In fact, the water ring vacuum pump can be used as a compressor. I don’t know whether it is like this in metallurgy or not. Because the principle of water-ring compressor and water-ring vacuum pump is the same, but there are some differences in import, export and structure. Some raw materials are flammable and explosive, such as hydrogen, water ring compressor can be used. Because oil and gas can not be mixed with water, dry pumps, such as screw pumps, are now used for oil and gas recovery in oil depots.

There is also a vacuum pumping equipment called water jet unit, which is a centrifugal pump through the ejector directly to achieve the purpose of vacuum pumping (supplement: water jet unit is also called water jet pump). The working principle is that the working medium water with a certain pressure is ejected at a high speed to the suction chamber through the nozzle, which changes the pressure of water into kinetic energy and forms a high-speed jet; the gas in the suction chamber is forced to carry and mix with it by the high-speed jet, forming a gas-liquid mixed flow and entering the diffuser, thus reducing the pressure of the suction chamber, forming a vacuum, and the kinetic energy of the mixed jet in the expansion section of the diffuser. Converting to pressure energy, the speed decreases, the pressure increases, the gas is further compressed, discharged with water outside the pump, gas and water are separated in the tank, gas is released into the atmosphere, water is recycled by the pump, and the purpose of vacuum pumping is achieved repeatedly.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)