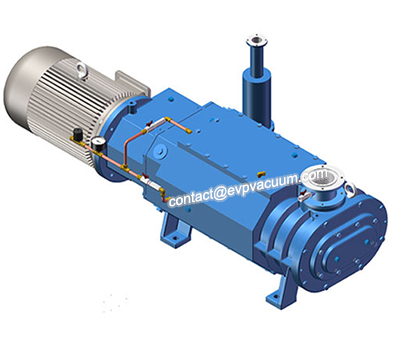

Compact dry screw vacuum pump

Provide you with screw vacuum pump / dry type / single stage / compact product details.

The operation principle of screw vacuum pump is dry compression back pump, and its operation is based on screw principle. The pump chamber of the pump consists of two synchronous positive displacement rotors and a housing which encloses these rotors. As the rotor rotates in the opposite direction, the chamber moves steadily from the intake side to the exhaust side of the pump, resulting in a smooth pumping effect.

How solve problem of screw vacuum pump compression

In the application of screw vacuum pump, sometimes there will be insufficient compression. Here’s how to deal with the insufficient compression of screw vacuum pump:

1. In the screw vacuum pump, the auxiliary automatic exhaust valve is a unique structure. Generally, rubber ball valve is selected. Its function is to deal with the over shrinking and insufficient shrinking caused by the screw vacuum pump in the whole process of operation. Both of these two conditions result in excessive output power consumption. Because the water ring vacuum pump does not have an immediate automatic exhaust valve, and the working pressure of the exhaust pipe is fixed from the beginning to the end, the compression ratio of the water ring vacuum pump is determined by the stop position of the air inlet and the start and stop position of the air outlet.These two positions are fixed and will not change, so they are not suitable for the change of the suction pressure

2. In order to deal with this problem of screw vacuum pump, rubber ball valve is usually set directly below the air outlet, so that when the working pressure of the exhaust pipe is too early in the cavity of screw vacuum pump, the gate valve will be opened automatically, and the steam body will be discharged, so as to deal with the over shrinking condition. Generally, in the design of water ring vacuum pump, the minimum suction pressure is used to determine the compression ratio, so as to determine the start and stop parts of the air outlet, so as to deal with the insufficient reduction

3. The capacity of the small cavity between the screw vacuum pump and the air outlet further reduces the gas pressure and further rises. When the gas pressure of the steam body exceeds the gas pressure of the exhaust pipe, the reduced steam body is discharged from the air outlet. In the whole process of the continuous operation of the screw vacuum pump, the whole process of respiration, reduction and exhaust pipe is continuously carried out, so as to achieve the goal of continuous vacuum pumping