Composition of the vacuum system

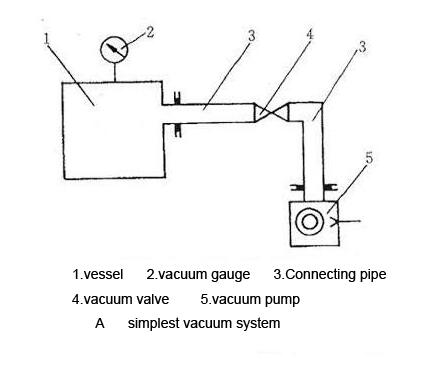

There are a wide variety of vacuum device, whatever vacuum device, there is always a pumping system that removes the gas from the vessel to obtain the required vacuum conditions in this vacuum vessel. For example: a vacuum processing vessel, which is connected to a vacuum pump by pipes and valves. When the vacuum pump pumps the vessel, the vessel has a vacuum measuring device, which constitutes the simplest vacuum pumping system. (Figure A).

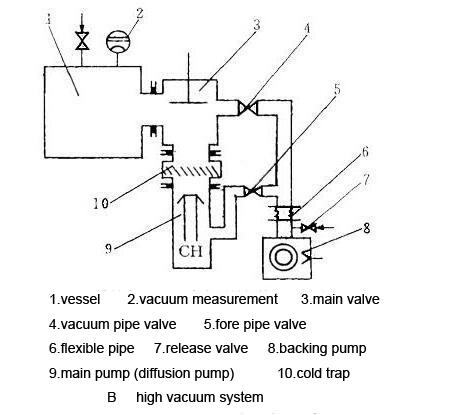

The simplest vacuum system (Figure A) can only achieve a vacuum in the low vacuum range in the vessel. When it is necessary to obtain a vacuum in the high vacuum range, it is usually connected a high vacuum pump in this vacuum system shown (Figure A). When a high vacuum pump is connected, the valves is usually added to the inlet port and outlet port of the high vacuum pump so that the high vacuum pump can maintain the vacuum alone. If the high vacuum pump is diffusion pump, in order to prevent a large amount of oil vapor from flowing back into the pumping vessel, the trap is usually added to the inlet of the oil diffusion pump – clod trip (Figure B). According to the requirements, it is also possible to add a dust remover, a vacuum relay gauge head, a vacuum soft connection pipe, a vacuum pump inlet bleed valve, etc. on the pipeline, thus forming a relatively complete high vacuum system.

A vacuum system consisting of two or more vacuum pumps, it’s usually called backing pump that pumps low vacuum, and it’s called main pump that pumps the highest vacuum in this vacuum system. The main pump mean it’s the mainly vacuum pump, the ultimate vacuum and working vacuum in the vessel are determined by the main pump. The pipe between the outlet of the vessel and the inlet of the main pump is called the high vacuum pipe, and the valve at the inlet of the main pump is called the main valve.

Usually the backing pump also called prevacuum pump. The pipe between the vessel and the backing pump is called the prevacuum pipe, and the valve on this pipe is called the prevacuum pipe valve. The pipe between the outlet of main pump and the inlet of the backing pump is called the fore pipe. The valve on this pipe is called the fore pipe valve, and the flexible pipe is set to isolate the vibration of the backing pump.

The basic content of the vacuum system design: according to the vacuum requirements of the vessel, select the appropriate vacuum system design, select and match the pump calculation; determine the conduit, valve, trap, vacuum measuring components, etc., for reasonable configuration. Finally, draw the vacuum system assembly drawing and parts drawing.

Tags : vacuum unit, diffusion pump ,vacuum parts ,vacuum valve

Edited by Jinny Zhang / EVP vacuum solution

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)