Corrosion resistant vacuum pump instructions

Corrosion resistant vacuum pump purpose and scope of use

The anti-corrosion vacuum pump is the second generation of improved type, which is specially used to pump or press corrosive gas without solid particles, so as to form vacuum or pressure in the container and meet the requirements of specific process flow. In the working process, this kind of pump compresses the gas under isothermal condition, so it is not easy to cause danger when it compresses or sucks flammable and explosive gas, so it is more widely used.

Anti corrosion vacuum pumps and compressors are widely used in machinery, petroleum, chemical industry, pharmaceutical, food, ceramics, sugar manufacturing, printing and dyeing, metallurgy, environmental protection and electronic industries with special requirements for corrosion.

Corrosion resistant vacuum pump working principle

This series of anti-corrosion vacuum pumps and compressors have carried out the third-generation anti-corrosion technology treatment for all the flow parts. The flow parts are lined with F4 (polytetrafluoroethylene) by special technology. The thickness of fluorine lining is about 12-15 times of the thickness of anti-corrosion spraying, which solves the problem of falling off easily in the current spraying anti-corrosion. At the same time, special material buffer layer is set in the new technology, which solves the problem of lining plate The pump is stuck because of the uneven thermal and cold expansion and the completely inconsistent expansion rate with the base casting. The service life and stability of this anti-corrosion treatment is much higher than that of traditional anti-corrosion treatment.

Corrosion resistant vacuum pump structure description

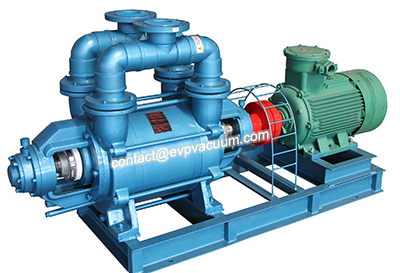

The pump is composed of pump body, front and rear end cover, impeller, shaft and other parts. The intake pipe and exhaust pipe are connected with the pump cavity through the suction hole and exhaust hole installed on the disc on the end cover. The impeller is fixed on the shaft with a key and installed eccentrically in the pump body. The total clearance at both ends of the pump is adjusted by the pad between the pump body and the disc. The clearance between the impeller and the front and rear discs is adjusted by the impeller driven by the shaft sleeve. The clearance at both ends is guaranteed to be uniform. The pump body, end cover, impeller, shaft and pipeline are all treated with special anti-corrosion technology.

Corrosion resistant vacuum pump equipment installation

Before installation, rotate the coupling by hand to ensure that there is no jamming or other damage in the pump. If the vacuum pump or compressor is normal, when the pump and motor are installed on the pump base, the concentricity between the motor shaft and the pump shaft shall be corrected, because if there is a small inclination between the motor shaft and the pump shaft, bearing heating and severe wear of parts will also be caused. The correction method is as follows: place the straight edge on the coupling in parallel, the straight edge shall be fully closed with the coupling circumference at any position of the whole circumference, without clearance, and when the axial clearance of the coupling is equal, the required concentricity is achieved, as shown in the figure: a filtering device shall be installed at the air inlet of the pump to prevent foreign matters from entering the pump cavity.