Dry Screw Vacuum Pump in Acetone Recovery

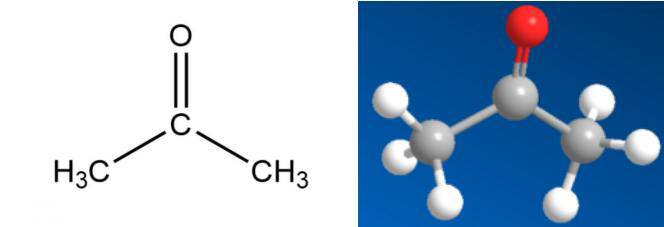

Acetone is an organic substance with a molecular formula of C3H6O. It is a colorless and transparent liquid with a special pungent odor. It is easily soluble in water and organic solvents such as methanol, ethanol, ether and chloroform. It is flammable, volatile, and chemically more active.

In industry, acetone is mainly used as a solvent in explosives, plastics, rubber, fiber, leather, grease, spray paint and other industries. It can also be used as a synthetic ketene, acetic anhydride, iodoform, polyisoprene rubber, and methacrylic acid. An important raw material for methyl ester, chloroform, epoxy resin and other substances.

In industrial production, the consumption of acetone is very large. In order to reduce costs, improve economic benefits, and reduce environmental pollution, acetone needs to be recycled.

At present, the most common methods of recovering acetone on the market are mainly membrane separation, combustion and condensation.

1.Membrane separation method

The membrane separation method is based on the difference in the ability of acetone and air in the mixed gas to permeate the membrane. It uses the selectivity of the membrane and the capillary condensation of the membrane micropores to enrich and separate the acetone gas in the exhaust gas. It was developed in recent years. new technology. Common membrane separation technologies include gas membrane separation, membrane-based absorption method and vapor permeation method. The membrane separation method has low energy consumption, large separation factor, good separation effect, simple operation, convenient control, large operation flexibility, and pure recovered materials; however, the initial one-time investment is large, and the selection of membranes is difficult.

2.Combustion method

The combustion method is also called the thermal destruction method, and it is also a commonly used method for treating organic waste gas. The combustion method is mainly divided into direct flame combustion method and catalytic combustion method. It uses direct oxidation and catalytic oxidation decomposition to destroy the organic molecules in the exhaust gas, so that it can generate low-toxic or non-toxic substances. So as to achieve the purpose of direct emission of volatile organic compounds. The combustion method has high purification efficiency, simple equipment structure and wide application range. However, during catalytic combustion, the cost of the catalyst is high and it is easy to cause catalyst poisoning; the economic benefit is small and it is easy to cause secondary pollution.

3.Condensation method

The condensation method uses the different vapor pressures of acetone gas to supersaturate the acetone by adjusting the pressure and temperature to cause condensation to separate the mixed gas of acetone and air to a greater extent, and the acetone is also recovered. The condensation method is simple to operate and does not produce any other components, so other separation operations are not required, and there is no secondary pollution. Condensation method to recover acetone technology has large processing batch flexibility, stable efficiency, and completely does not consume the steam of regenerated activated carbon.

With the development of the condensation method, vacuum pumps are playing an increasingly important role. The vacuum pump used in the acetone recovery process is the first choice for dry screw vacuum pumps. Dry screw vacuum pumps are technological products with very high technical content. They are mainly used in high-purity vacuum processes. The vacuum is extremely high and can adapt to harsh working conditions. The ability to extract condensable and particulate gas is particularly suitable for clean environments and easy to do anti-corrosion treatment. It is especially suitable for electronics, chemicals, biomedicine, metal processing, food processing and other fields.

The dry screw vacuum pump produced by Shanghai EVP Vacuum Technology Co., Ltd. uses a pair of screws to perform synchronous high-speed reverse rotation in the pump casing to produce suction and exhaust air suction equipment. The two screws are finely balanced. It is calibrated, supported by bearings and installed in the pump housing. There is a certain gap between the screw and the screw. Therefore, when the pump is working, there is no friction between each other, smooth operation, low noise, and the working chamber does not need lubricating oil, so it can be pumped Except for gas occasions containing a large amount of water vapor and a small amount of dust, the ultimate vacuum is higher, the power consumption is lower, and it has the advantages of energy saving and maintenance-free.

The type of screw pump commonly used in acetone recovery applications is LG-50/70/110, and the pumping speed is 50L/s, 70L/s, 110L/s.

EVP Vacuum has extensive experience in Acetone recovery, please feel free to contact sales team.

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)