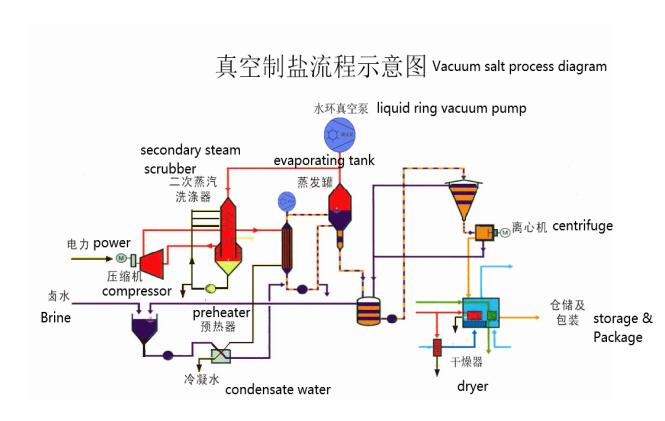

Liquid ring vacuum pump with jet pump in vacuum salt production application

Introduction

Vacuum evaporation salt production is also called “vacuum salt production”, which is a modern salt production process.

Salt is made using the principle that brine evaporates in the evaporation system at a state lower than the outside atmospheric pressure (negative pressure). There are two main processes, evaporation and crystallization, dehydration and drying. The process flow is different due to the different raw materials used, product use, and production energy use methods. China mostly uses vacuum evaporation, centrifugal dehydration, and boiling drying processes.

After the vacuum salt-making equipment is completed and put into production, people always try to increase the first-effect heating steam pressure and the ineffective vacuum to increase the effective temperature difference and increase the output. However, the nature of water vapor is that the temperature increases slowly, and the pressure increases quickly. This is limited to the relationship between the boiler capacity and the mechanical strength of the equipment, and the first-effect heating steam pressure cannot be increased indefinitely; generally, the first-effect steam pressure is controlled by 4kgf/cm~2 (Absolute pressure) around. Therefore, in actual production, for the increase of the total temperature difference, the main requirement is to increase the vacuum degree of the end effect.

Overview of vacuum salt production process

Due to the different production conditions and raw brine, the production process of vacuum salt production is not the same, but the basic production process is the same. The basic processes of salt production are: brine preparation and treatment process; Evaporation crystallization process; Dehydration process; Packaging and storage process; Heating process; Six major processes, such as transportation and auxiliary process.

1.Brine treatment process

According to different sources, brine in brine treatment process can be divided into natural brine and artificial brine. Hot brine has barium yellow brine, black brine, salt lake brine, oil and gas brine, etc; Artificial brine can be divided into calcium sulfate brine and sodium sulfate brine. Brine is not pure sodium chloride solution, brine also contains many other substances, such as iron, gypsum, mirabilite, magnesium, lead and other substances. They yo have a sound from the hair plug of the hulls, you are like a man to reduce food and health. The acid adheres to the scale, so that the production under the production capacity may affect the health of the body, so the brine steaming system ensures the health of the body.

2. Evaporation crystallization process

Evaporation crystallization process is the heat transfer and heat exchange between the purified brine after brine treatment and the back pressure steam from the power station. Because vacuum evaporation is used, the secondary steam of the former effect and the brine of the next effect can also conduct heat transfer, so as to carry out heat exchange. After brine boiling evaporation, the solvent evaporates in the form of secondary steam, and the solute crystallizes from the solution.

3.Dehydration and drying process.

As mentioned earlier, the material discharged from the evaporation and crystallization process of salt making is salt slurry. The water content of the salt slurry is between 20% and 40%. In the dehydration and drying process, the centrifuge is used to separate the salt slurry with 20% to 40% water content in its high-speed rotation to obtain the wet salt with 3% water content, and then the drying equipment is used to use the hot steam of the power station as the energy, The water in the wet salt is evaporated to obtain the dry salt with water content less than 0.3. Therefore, dehydration and drying is actually divided into centrifuge dehydration and drying two parts.

4.Packaging and storage process

The process of packaging and storage is to transport the finished salt by belt, send it to the package for packaging measurement, and then put the packaged finished salt into the warehouse. Packaging can be divided into large and small packages. Large packages are generally divided into kilos, and some large packages are 1000 kilos. Small package is the edible salt in bags and films that we see on the market. There are 400g, 500g and 1000g types. Storage is to deliver the packaged finished salt to the storage department. The storage department is responsible for the storage and storage of the finished salt and the storage and protection of the finished salt in the finished product warehouse.

5、 Heating process

Heating process is the use of boiler equipment to provide steam, or the use of back pressure steam after power generation to provide heat

6. Auxiliary process

The auxiliary system of salt production line includes water supply (circulating cooling water, once through water). Power supply, instrument, mechanical and electrical maintenance, laboratory testing and analysis.

The following is the flow chart of vacuum salt production