Vacuum pumps are used in the dilute brine dechlorination industry

Nowadays, in many industries, it is necessary to dechlorination, Familiar ones such as dilute brine dechlorination.

When it comes to dilute brine dichlorination, it has to mention the ionic membrane electrolytic production caustic soda technology. Now the ionic membrane electrolytic production caustic soda technology is becoming more and more mature, and the removal of free chlorine in dilute brine and processing into qualified dilute brine is an essential process in the production of ionic membrane caustic soda.

1. Sources and hazards of free chlorine in dilute brine

Generally speaking, the free chlorine contained in the dilute brine flowing out of the groove of ionic membrane electrolytic production caustic soda will exist in the form of dissolved chlorine gas, and the dissolved amount is related to the temperature and concentration of the dilute brine and the partial pressure of the chlorine above the solution. Free chlorine exists in the dilute brine, which will corrode the equipment and pipelines of the brine refining system, hinder the generation, flocculation and precipitation of Mg(OH)2 and CaCo3 in the brine refining process, reduce the sedimentation speed of particles, and affect the clarification effect of the brine. In the process of salting and refining, the environment is polluted due to the diffusion of chlorine gas. Free chlorine also corrodes the sintered carbon tube and causes the ion exchange chelating resin to be poisoned and invalidated.

2.Principle of removing free chlorine in dilute brine

Simply put, the presence of chlorine in dilute brine is chemically in a state of equilibrium, and dechlorination is to destroy the above-mentioned equilibrium relationship. Because the solubility of chlorine in water (including salt water) is very small. In the production practice of the dilute brine solution, sufficient chloride is added to the dilute brine to eliminate the dissolution of free chlorine in the dilute brine and the reaction balance proceeds in the reverse direction until the chemical balance and phase balance are destroyed. Removal of free chlorine in dilute brine, all free chlorine cannot be completely removed, the remaining free chlorine needs to be added with reducing substances for chemical reaction, so as to completely remove free chlorine.

3.emoval method of free chlorine in light brine

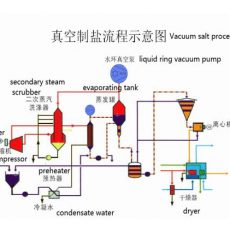

There are many common dechlorination methods, such as vacuum dechlorination (decompression method).

Dechlorination by reduced pressure is to inject an appropriate amount of hydrochloric acid into dilute brine, and to remove chlorine gas and recycle it while maintaining a high vacuum.

A common choice is to use a liquid ring vacuum pump, which generates a vacuum through the high-speed operation of the liquid ring and impeller in the liquid ring pump to suck the gas (including water vapor) in the dechlorination vacuum device, and the separated chlorine enters the chlorine gas manifold, The excess chlorine water is sent to the dilute brine tank for treatment. If vacuum dechlorination is combined with other auxiliary dechlorination methods, it has become an important method commonly used in the chlor-alkali industry to effectively remove free chlorine in dilute brine.

The vacuum pump provided by Shanghai EVP Vacuum Technology Co., Ltd. can meet the needs of different customers in different models/sizes of dechloination equipment. Among the several vacuum pumps that are selling well are:

1.2BE liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 246m3/h-9450m3/h.

2.2BV liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 27m3/h-500m3/h.

3.DLV two stage liquid ring vacuum pump, the ultimate vacuum is 33hpa, and the gas volume is 145m3/h-1,589m3/h

EVP Vacuum has extensive experience in the vacuum dechloination, and can customize to meet customer’s needs, providing special materials, such as titanium materials.

If you have product needs, please feel free to contact us. According to the specific information you provide, we will design the most appropriate scheme for you. For example, this is a selection for one of our customers, the required technical parameters:

Medium: H2O vapor and little inert gas.

Intake temperature: 40 ℃

Working liquid temperature: 35 ℃

Voltage: 380V 50Hz, 3Ph.

Pumping speed: 55 Nm3/hr

Operating vacuum: 150 Torr,

If you have any questions, please feel free to contact us and look forward to your consultation.

Copyright: EVP Vacuum Solutions

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)