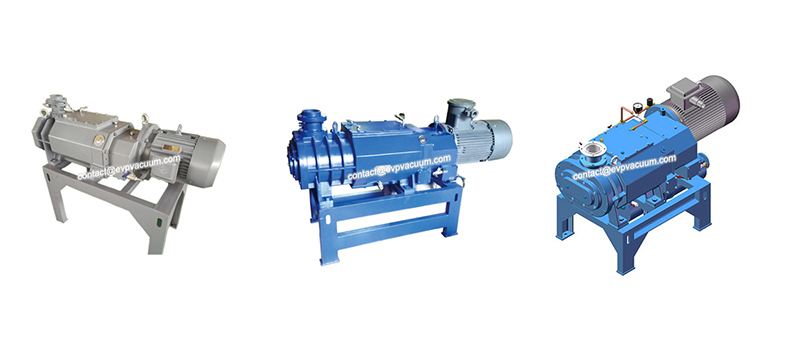

dry screw vacuum pump wear causes

Next, EVP vacuum pump manufacturer will introduce the causes of screw vacuum pump wear?

1、 If there are fillers such as calcium carbonate and glass fiber, the wear of screw and barrel can be accelerated.

2、 Temperature scale:

(1) everyone has an ambitious temperature scale for plastic processing. The processing temperature of the barrel shall be controlled so that it is close to the temperature range.

(2) in the shrinkage and homogenization part, if the melting state of the plastic is disordered and uneven, the wear will increase.

(3.) when granular plastics enter the barrel from the hopper, they will first reach the feed section. Dry friction is inevitable in the feed section. When these plastics lack heat and melt unevenly, it is easy to form the inner wall of the cylinder and the outer wear of the screw increases.

3、 The speed shall be adjusted properly:

(1.) because some plastics are reinforced, such as fiberglass, minerals or other fillers. Compared with molten plastics, these materials have greater friction on metal materials.

(2) when dry screw vacuum pump manufacturers introduce injection molding, if high-speed conversion is used to increase the shear force of plastic, the reinforced material will also produce corresponding tearing fibers. The torn fiber has a sharp end, which greatly increases the wear force.

(3) when inorganic minerals slide at high speed on the metal surface, their scraping effect is not small. So the speed should not be too high.

4、 When the screw is rolling in the barrel, the conflict between the material and the barrel causes the working appearance of the screw and the barrel to wear gradually.

(1) the diameter of screw decreases and the diameter of inner hole increases. In this way, with the gradual wear of screw and barrel, the diameter gap between screw and barrel increases gradually.

(2) since the resistance of the head and the deflector in front of the barrel has not changed, the leakage flow of the extruded material is increased, that is, the material flow is increased from the diameter gap to the feed direction.

(3) the production of plastic machinery is reduced, which in turn causes the material to stay in the barrel longer, leading to material differentiation. In the case of polyethylene, the corrosion of screw and barrel is enhanced by hydrogen chloride gas generated by differentiation.

5、 Due to the fact that the material is not uniformly plasticized or mixed with metal foreign matters, the screw rolling torque is suddenly added, which exceeds the strength limit of the screw.