Dry screw vacuum pump working principle

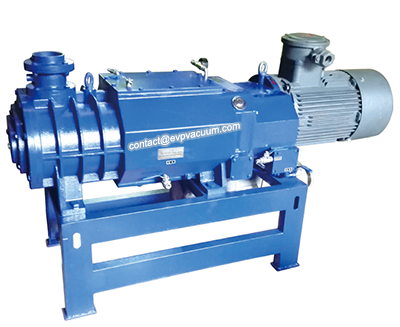

Dry screw pump is a new type of vacuum pump, which is mainly developed to replace the traditional water ring vacuum pump, oil ring vacuum pump and other pump. Because of its unique design principle, can do no oil no water, can do corrosion resistant coating, excellent seal design, in addition to a little more expensive, no matter from any aspect will be far more than the performance of the traditional vacuum pump. How to judge whether the dry screw vacuum pump is qualified can be judged from the following aspects:

1. Ultimate vacuum:

Of course, the lower the ultimate vacuum, the better. Currently, domestic products are generally around 5Pa, while imported ones are around 1Pa.

2, vibration and noise: the vibration must be small, noise must be less than 80 db.

3, if there is easy to use in the corrosive environment, it is best to ask the manufacturer for a bit of the same coating sample, take the factory to put the medium solvent test, each manufacturer used coating or coating ratio is not the same, its performance of course will also have a big difference.

4, sealing: this is also very important, but also can only from the manufacturer’s recommendation to understand, the most direct or access to the system after medium measurement is not leaking.

Basically is the above points to judge, the first and second points determine the level of vacuum pump machining and design technology, which will really affect the service life of the vacuum pump, the third and fourth points will also affect its life, but also need to be proved by experiments. Generally speaking at present screw pump because of the high cost, it is recommended to choose imports, Europe, America and South Korea is relatively expensive, Taiwan is actually a good choice.

Dry screw vacuum pump is a very high technical content of science and technology products, mainly used in vacuum process of high purity, high vacuum degree, can adapt to bad working condition, have the ability to extract condensate, the particulate gas, especially suitable for clean environment, and easy to do the anti-corrosion treatment, especially suitable for electronic, chemical industry, biological medicine, metal processing, food processing and other fields.

1. There is no medium in the working chamber, so a clean vacuum can be obtained

2. Anti-corrosion coating is provided on the surface of working cavity and screw rotor, which can adapt to harsh working conditions

3, the gas in the vacuum pump is not compressed, suitable for extraction of condensable gas

4, a single vacuum pump can be pumped from the atmosphere to 1Pa, the vacuum system can be greatly simplified.

5. The water temperature has little influence on the vacuum, saving more than 90% water and even no water consumption.

6, no oil consumption, no leakage

7, no friction between the rotating parts, can run at high speed, small machine size

8. Simple structure and easy maintenance.

9. The pumped gas is directly discharged from the vacuum pump body, which does not pollute water and has no environmental protection pressure, making gas recovery more convenient.

10. Oil-free unit can be formed with roots vacuum pump and molecular pump

Similar to screw compressor, screw dry vacuum pump can be divided into suction, compression and exhaust three processes. As the rotor rotates, each pair of teeth meshing with each other successively completes the same cycle of work.

The positive rotor rotates counterclockwise and the negative screw rotates clockwise. The upper end of the rotor in the figure is the suction section, and the lower end is the exhaust end.

Turn on the end face is the exhaust end face. Here, the Yang rotor rotates in a clockwise direction and the Yin rotor in a counterclockwise direction. The upper end of the rotor in the figure is the suction section, and the lower end is the exhaust end.

Screw vacuum pump exhaust process, the volume between the teeth and exhaust port after the connection, that is the start of the exhaust process. With the decreasing of the volume between the teeth, the gas with exhaust pressure is gradually discharged through the exhaust orifice.