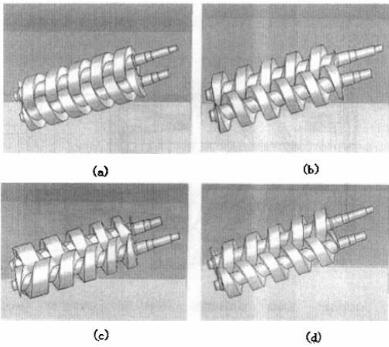

dry screw vacuum pumps several common rotors

At present, the main manufacturers of dry screw vacuum pump mostly adopt single-head equal pitch profile, and other symmetrical circular arc profile, single-head variable pitch trapezoidal thread profile, single-head equal pitch trapezoidal thread profile and equal pitch concave tooth profile.

(a) single head and equal pitch rectangle threaded rotor

(b) single head and other pitch trapezoidal threaded rotor

(c) single head variable pitch trapezoidal threaded rotor

(d) single head and equal pitch concave rotor

The profile of rectangular threaded rotor with single head and equal pitch is the earliest one. Because of the possibility of undercutting, i. e. interference between two stages of rotor, it is basically no longer used. Instead, the improved single-head equal pitch trapezoidal screw rotor, whose section shape is changed from rectangular to trapezoidal, solves the problem of interference, and is easy to process, so it is widely used by manufacturers.

Single-head variable pitch trapezoidal screw rotor and single-head equal pitch concave rotor are new types of rotor in recent years. They are improved on the basis of single-head equal pitch trapezoidal screw rotor. The main characteristics of the single-head variable pitch trapezoidal screw rotor are that the screw pitch varies according to the variable pitch coefficient from the suction end to the exhaust end, and the one end of the large lead corresponds to the suction port. Initially, the suction capacity is large, the closed cavity moving in the process of rotor rotation is smaller and smaller, the gas is compressed, with the role of internal compression, that is, while conveying side compression, so as to reduce the overall exhaust compression power consumption, and the occurrence of the exhaust surge phenomenon has been inhibited, is more stable pump work, can be reduced. Noise and exhaust vibration.

The concave surface of the first-class pitch rotor further uses the internal concave tooth surface method to remove all possible interference parts on the meshing tooth surface, which is the conjugate surface of the equal pitch helix with inward concave tooth surface. Multi-head bilateral symmetrical circular arc profile is a new type of profile in recent years. It is developed on the basis of twin screw compressor profile. The general rotor is four screw and the negative screw is six screws.

Each of the above-mentioned profiles has its own advantages and disadvantages, and should be selected according to the design requirements, manufacturing capacity, actual needs and other aspects. From the aspect of applicability, the two sides symmetrical circular arc line has the widest application. Because the line can complete the whole process of suction, compression and exhaust in one lead and reach a certain limit vacuum, it can effectively reduce the volume and mass of the pump, especially suitable for pumps with large pumping speed requirements. Single-head profile is suitable for medium and small-sized pumps because it needs multi-stage to reach a certain limit of vacuum, which inevitably increases the volume of the pump and occupies more space.

The drawback of multi-head screw profile is that the profile is complex and expensive to be processed, so it needs special cutting tools to be processed on the special machine tool; and the single-head trapezoidal profile is straight line because the intersection of each tooth surface in the axial section, so the straight-edged turning tool can be used in machining, but the variable pitch profile is processed on the NC lathe to ensure the accuracy. . The machining of single concave tooth profile is slightly more complicated than that of trapezoidal tooth profile, but it can be completed completely on general NC lathe, and casting can be used in mass production. In addition, the multi-head screw thread and the single-head variable pitch thread are not suitable for the removal of condensable gas due to internal compression during the exhaust process, but reduce the surge and noise of the exhaust port, and also reduce the power consumption.

(The article comes from the Internet. If reprinting is not allowed, please contact our company to delete it.)